Preparation method and application of ultrathin fiber slice

A technology of ultra-thin slices and fibers, which is applied in the preparation of test samples, material analysis using radiation, material analysis using wave/particle radiation, etc. It can solve the problems of flexible fiber sample preparation difficulties and easily damaged fiber structures, etc. Achieve the effect of not easy to peel off or pores, improve the contact interface, and increase the interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

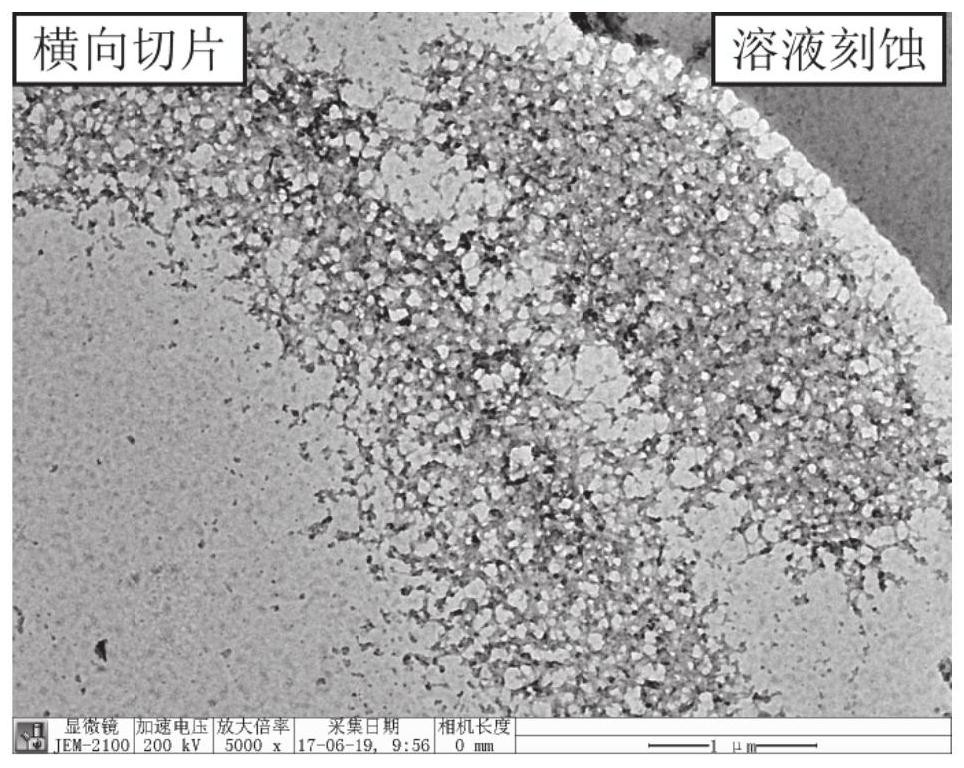

[0025] The first aspect of the present invention provides a method for preparing fiber ultra-thin slices, comprising the following steps: freeze-drying, embedding, trimming, slicing, solution etching, and drying.

[0026] In one or more embodiments of the present invention, the polyacrylonitrile fibers are preferably as-spun fibers, washed fibers, densified fibers, precursors, and pre-oxidized fibers.

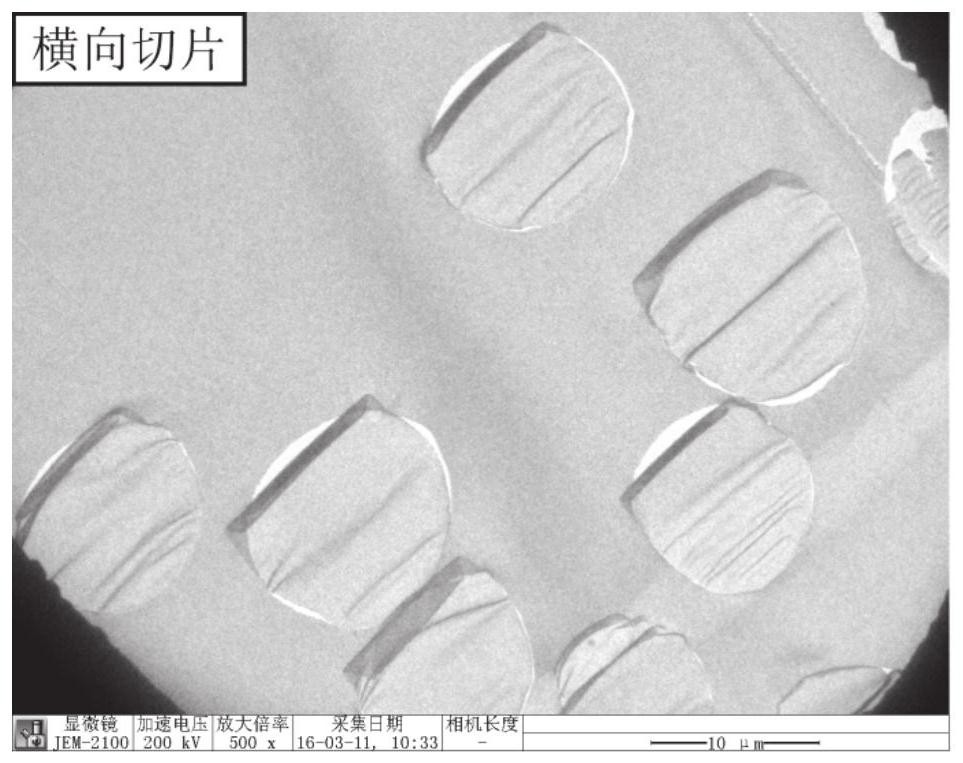

[0027] There are various types of fibers. Taking polyacrylonitrile fiber as an example, the internal organization of polyacrylonitrile primary fiber is a sheet structure, and the sheets are arranged perpendicular to the fiber axis, and there are many pores between the sheets; during the pre-drawing stage of the coagulation bath, The microfibril structure began to appear, and the microfibrils were arranged parallel to the fiber axis. After multi-stage drafting and densification, the microfibrils were arranged more closely, and the microfibrils were not arranged in parallel. Ther...

Embodiment 1

[0066] Such as figure 1 Shown, a kind of preparation method of fiber ultrathin section comprises the following steps:

[0067] (1) Pretreatment of fibers: some polyacrylonitrile fibers (as-spun fibers, washed fibers) contain dimethyl sulfoxide and water, which need to be freeze-dried. Drying fibers: put the fibers in liquid nitrogen for 10 minutes to make the fibers Quickly freeze, and then put the fiber into a special freeze dryer, and dry it under vacuum for 24 hours at -70°C to obtain a dry sample.

[0068] (2) Sample embedding: Cut the clean fibers into micro-segments of 2-4mm, add 3-4 drops of Epon812 epoxy resin to the embedding hole of the latex embedding plate, and use tweezers to vertically or Parallel to the long axis of the embedding hole, put it into the embedding hole, and then drop the resin until the embedding hole is full. The embedding plate was cured in a vacuum oven for 12 hours at 37°C, 12 hours at 45°C, and 48 hours at 60°C.

[0069] (3) Trimming: rough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com