Ceramic vapor chamber structure provided with fins and based on tape casting method and manufacturing method of ceramic vapor chamber structure

A production method and technology of soaking plates, which are applied in heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as poor heat soaking performance and poor thermal conductivity, and achieve improved working fluid reflux capacity, Optimize the packaging structure and enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

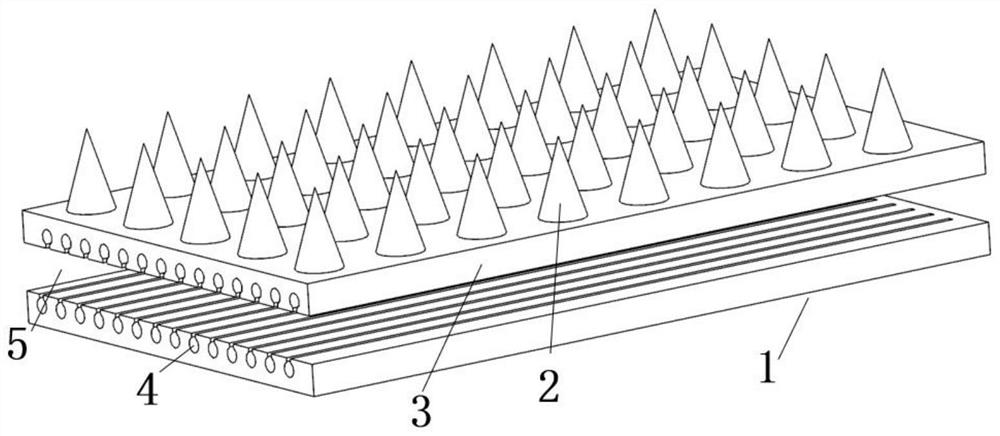

[0040] Such as Figure 1 ~ 5 As shown, a ceramic heated plate structure having fins with fins, including a heated plate, fins 2, and a working fluid, a heating plate comprising upper plate 3 and a lower plate body 1, a plate body There is a chamber between the 3 and the lower plate body 1, and the intermediate forming chamber is easy to evacuate and inject the dielectric fluid. The hot plate is designed as a quadrilateral, circular or trapezoid according to the required heat transfer shape.

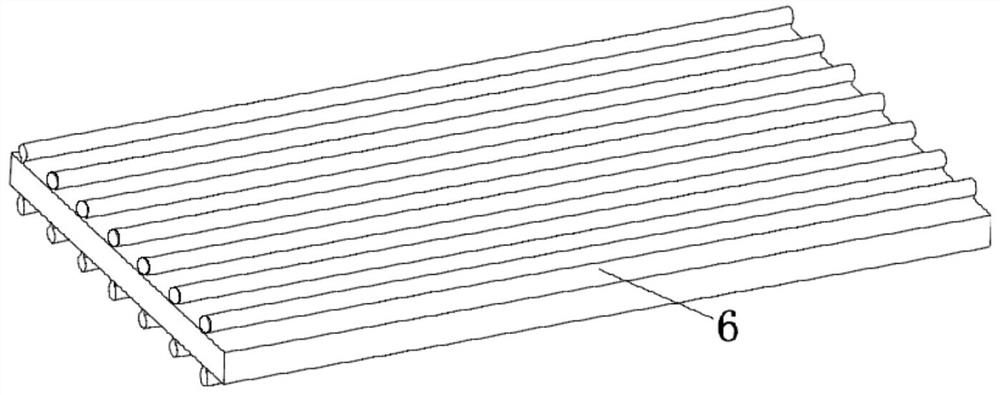

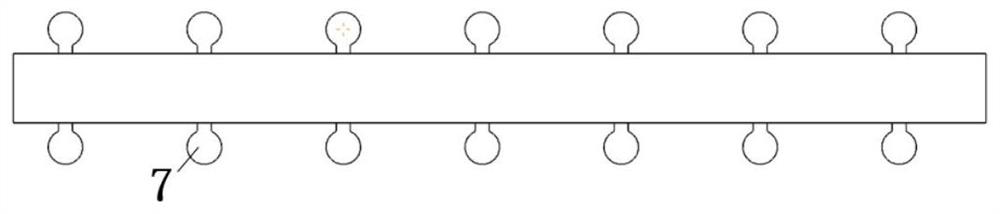

[0041] The upper plate body 3 body has a plurality of fins 2, and the specific fins 2 shape can process the regular geometrics, cylinders, cones, spirals, etc. of the wax mold, can be machined in the wax mold, can also be complex by machining and molding methods. The three-dimensional geometry is formed into a fin 2 inverse shape, and then wip the inversion of the inversion of the casting, and the fin 2 is obtained after solidification. Both the upper surface of the upper plate 3 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com