Golf club head

A golf club head and composite technology, which is applied to golf balls, golf clubs, sports accessories, etc., can solve the problems of high cost, high density, and heavy weight, and achieve reduced metal consumption, good plastic fluidity, and improved The effect of design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

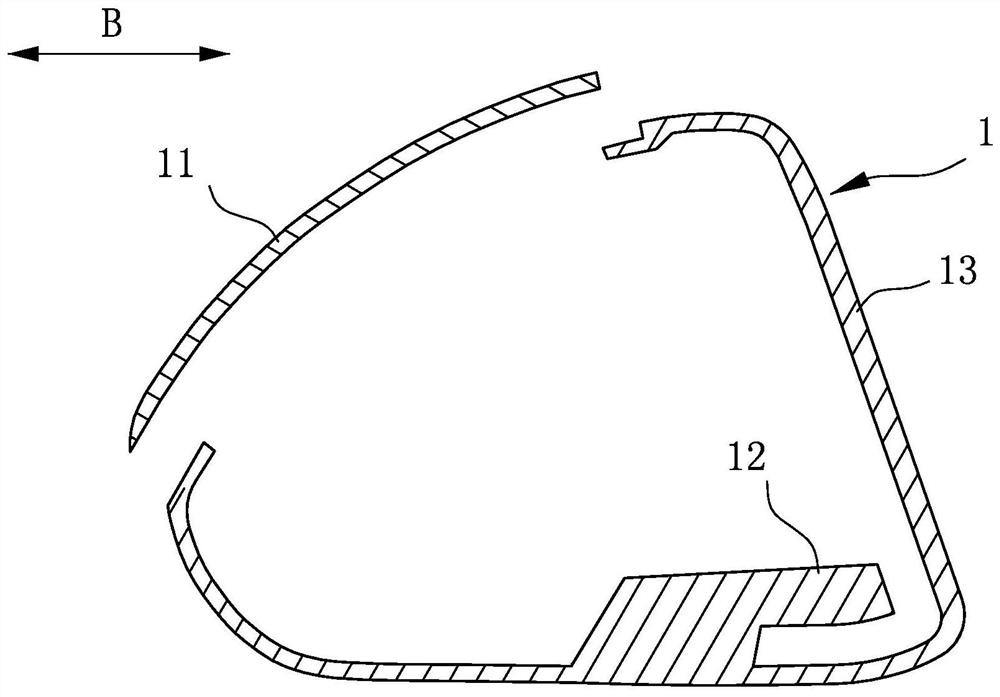

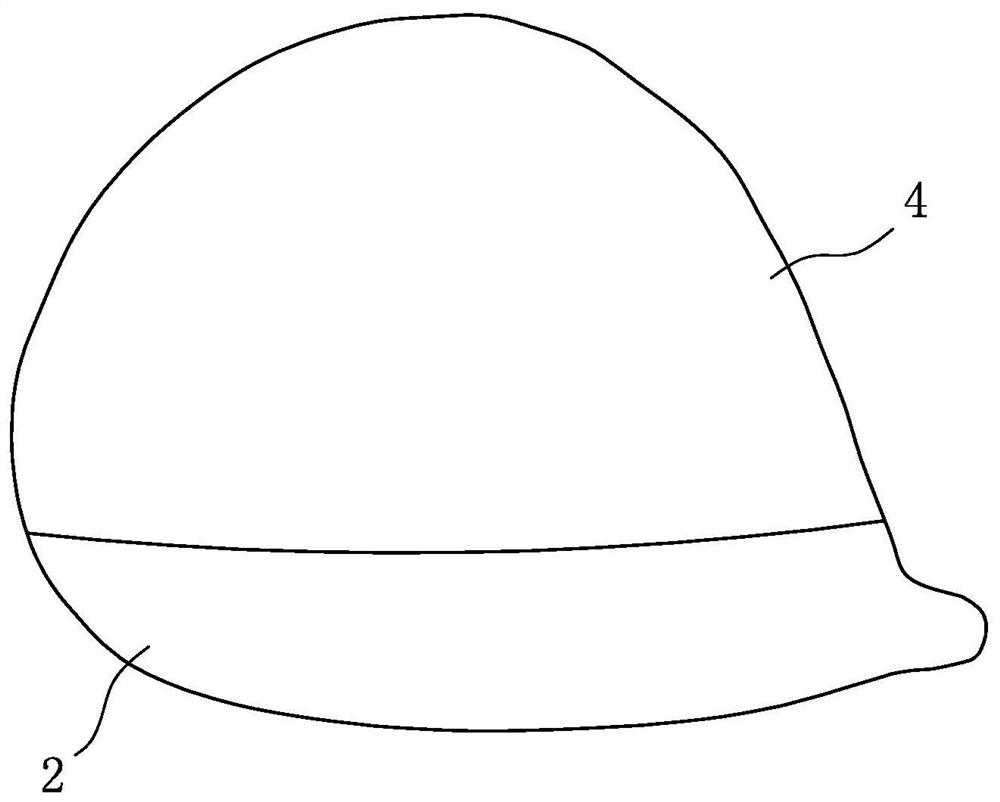

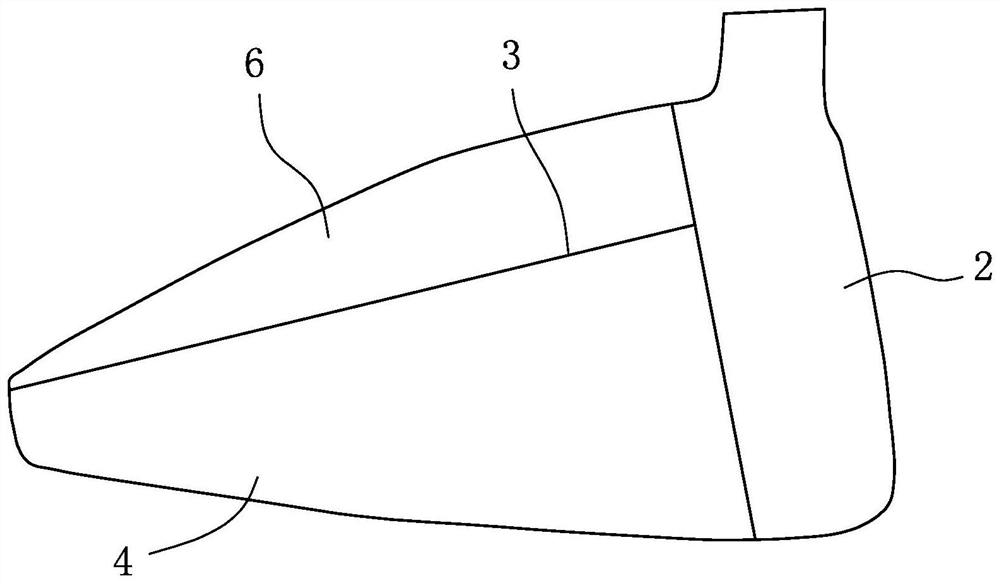

[0027] refer to figure 2 , image 3 ,and Figure 4 , is the first embodiment of the golf club head of the present invention, comprising a metal piece 2, a composite body 4 that connects the metal piece 2 and cooperates with the metal piece 2 to define an opening 3, and a composite body 4 fixed on the metal piece 2 The accessories 5 on the composite body 4, and a top cover 6 that connects the metal part 2 and the composite body 4 and closes the opening 3. In this first embodiment, the metal part 2 can be the hitting panel (CUP FACE) of a golf club head according to actual needs; 5, the plastic with high fluidity can be molded into arc-shaped and complex shapes, and the structural strength of the composite body 4 can be maintained by covering it with a carbon fiber plate with a high molding limit, and a single Shapes that carbon fiber panels cannot make. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com