Testing method and loading device for reinforced concrete bond-slip performance based on corrosion and fatigue load coupling influence

A reinforced concrete, bond-slip technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as low efficiency, easy slurry leakage, uncontrollable loading rate, etc., and achieve the effect of convenient operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The method for studying the bond-slip performance of ordinary deformed steel bars, corroded deformed steel bars and concrete based on beam end components of the present invention will be described in detail below in conjunction with the accompanying drawings.

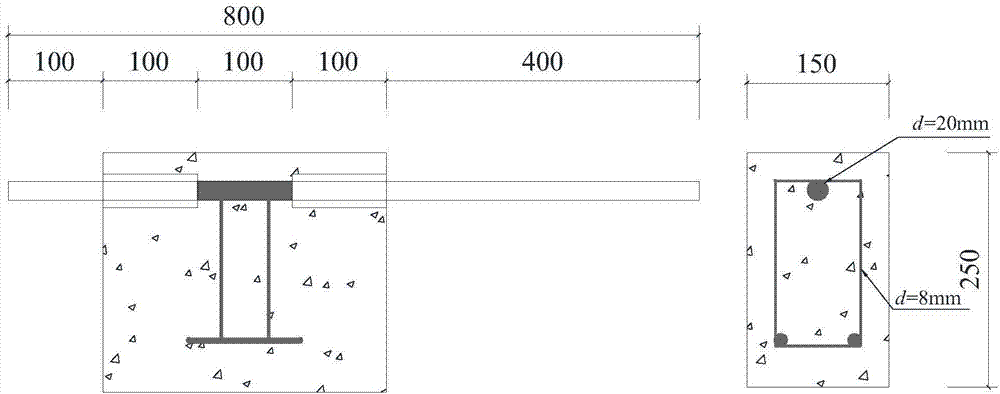

[0045] like figure 1 As shown, step 1: test block pouring

[0046] Make a wooden mold whose length, width and height are 300×150×250 mm, and punch holes at both ends of the wooden mold along the length direction. There are two round holes with a hole diameter of 25mm on the bottom side of the wooden formwork. The distance from the center of the hole to the bottom is determined by the thickness of the protective layer, and the distance to both sides is 75mm; there are four round holes with a hole diameter of 8mm on the top of the wooden formwork. The distances from the center to the sides and top are 30mm and 50mm, respectively. Place stirrups in the wooden formwork, and insert 20mm hot-rolled deformed steel bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com