Two-phase driving flexible paw

A flexible and gripper technology, applied in the field of soft robots, can solve the problems of high cost and high noise, and achieve the effects of low cost, no noise, and increased thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

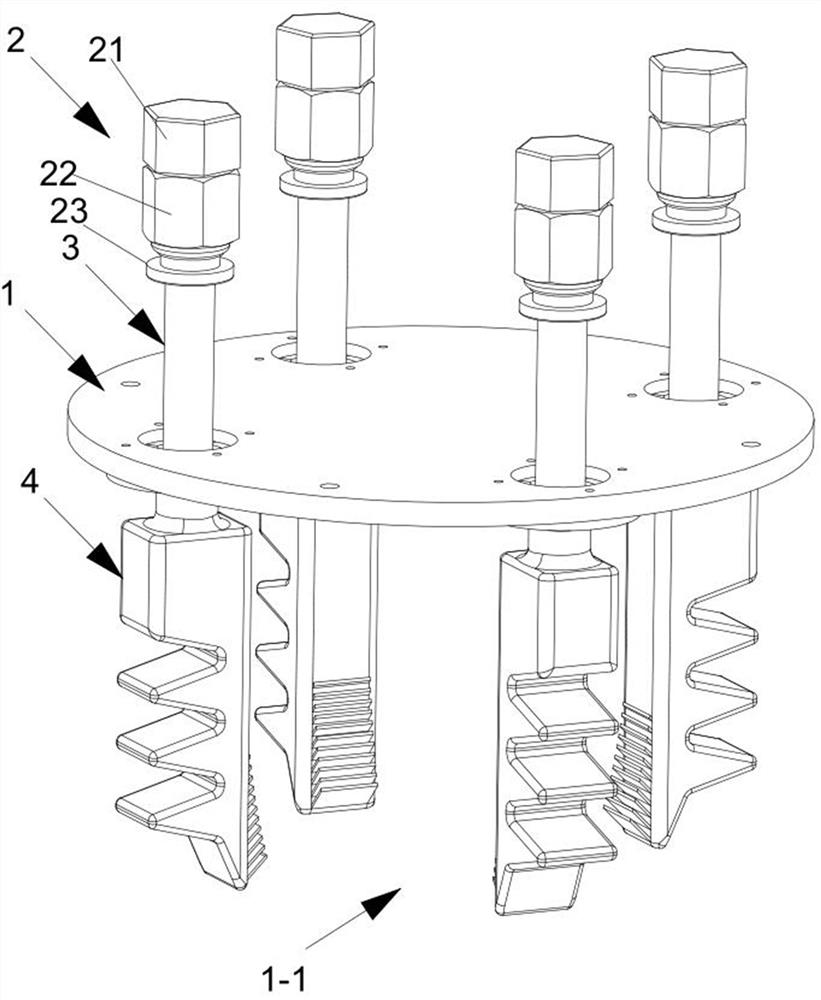

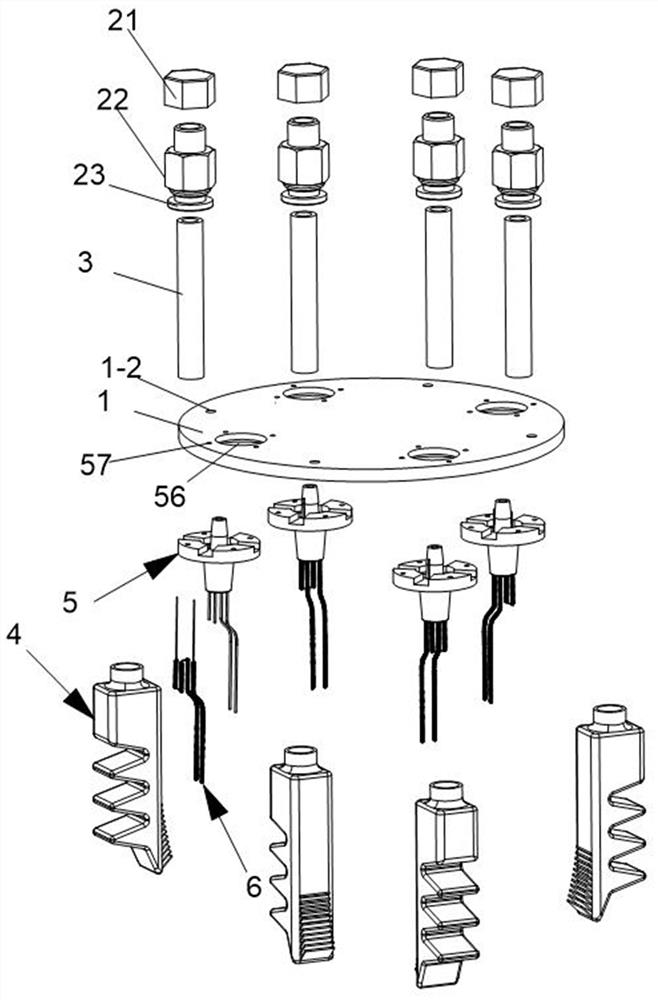

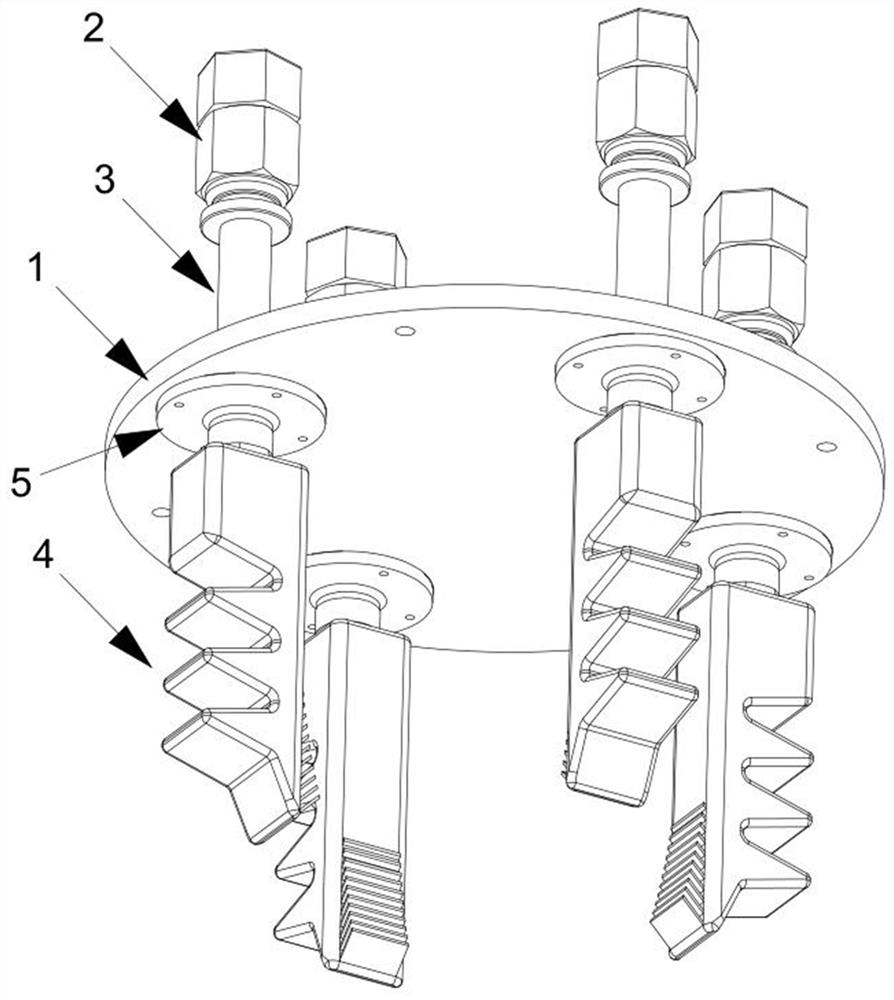

[0034] like Figure 1-Figure 6 As shown, a two-phase drive flexible gripper provided in this embodiment includes a gripper base 1, a sealing device 2, a trachea 3 and a hollow flexible gripper 4, and a gripper base 1 is provided below the gripper base 1. In the above-mentioned flexible clamping jaws 4, the upper part of each flexible clamping jaw 4 is communicated with the lower port of the air pipe 3 through a driving plug 5, and a sealing device 2 is connected to the upper port of each air pipe 3. , the lower part of the driving plug 5 is connected with a heating wire 6 inserted into the hollow of the flexible jaw 4, and the driving plug 5 is provided with a delivery hole 7 that communicates the hollow part of the flexible jaw 4 with the trachea 3. The flexible gripper 4 described above is filled with a low-boiling liquid of type HFE7000. The low boiling point liquid described in this example adopts HFE-7000, which is an electronic fluoride liquid product with no flash poin...

Embodiment 2

[0054] like Figure 14 As shown in the figure, for a two-phase drive flexible gripper provided in this embodiment, in order to prevent the material of the prism tooth shell 42 from being scalded after being added inside, the heating section 64 is covered with more than one spacer set at intervals. The heat ball 64-1, by covering the heating section 64 with a plurality of heat insulation balls 64-1, can prevent the material of the prism tooth shell 42 from being scalded after being added inside, thereby damaging the jaws and reducing the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com