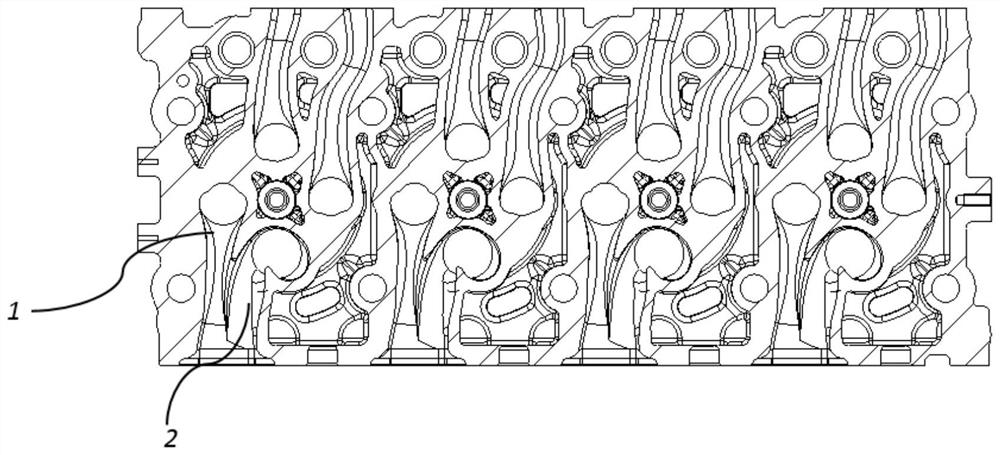

Air valve, air cylinder cover and engine

A cylinder head and engine technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of large gas flow loss, unfavorable engine fuel consumption, low flow coefficient of spiral air passage 2, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

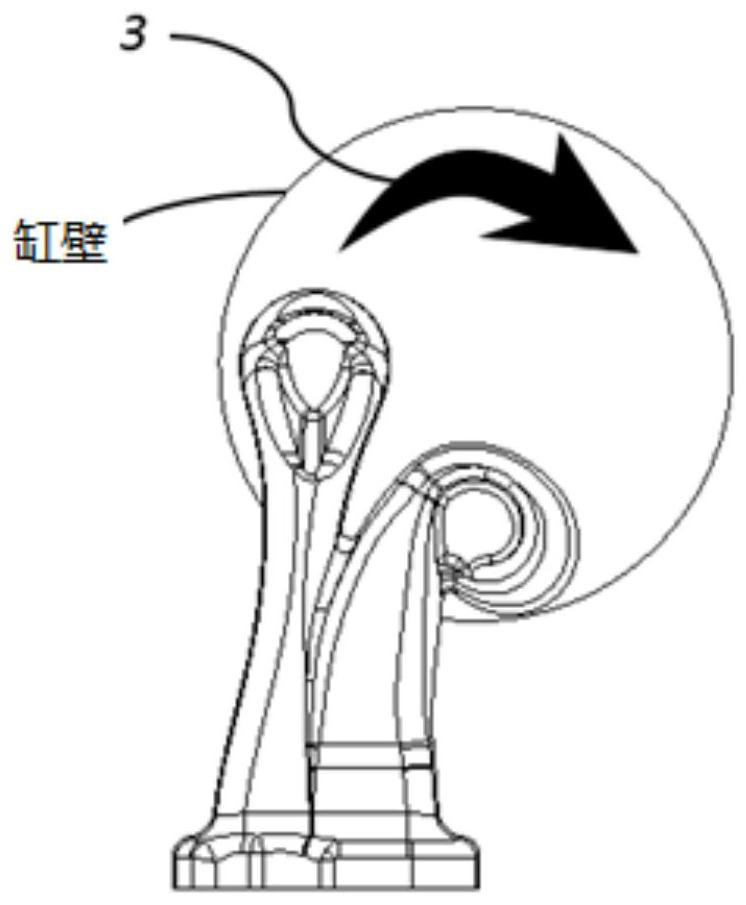

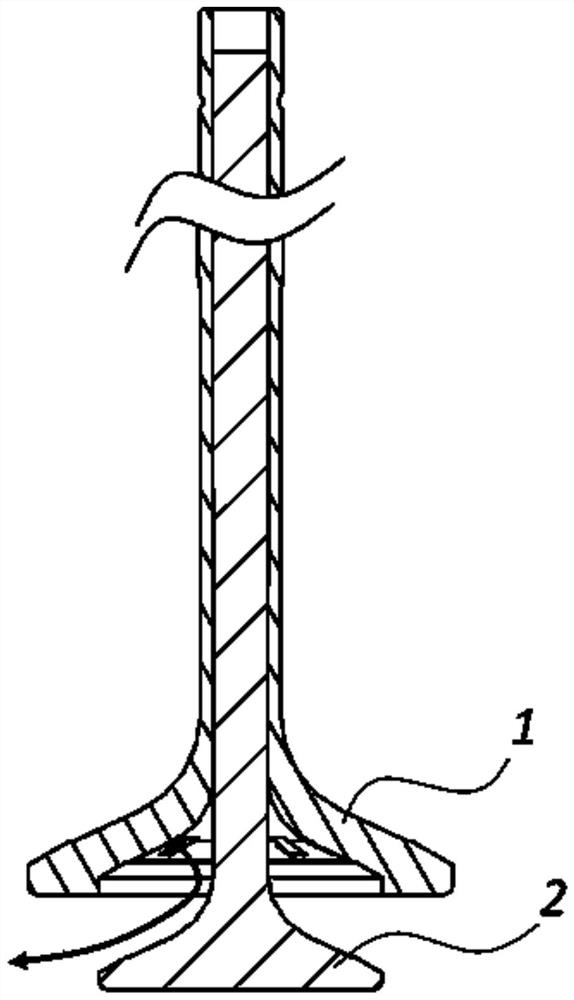

[0026] The embodiment of the invention discloses a valve, which rotates the air flow to form a vortex through the vortex generating hole on the vortex generating valve, and can cooperate with the spiral air channel to generate a spiral air flow with greater strength and a higher vortex ratio. Compared with the prior art In the method of generating vortex only through the spiral air channel, it can reduce the shape restriction on the spiral air channel, reduce the vortex ratio of the spiral air channel, improve the flow coefficient of the spiral air channel, and reduce the flow loss of gas during the intake process, which is beneficial to Reduce engine fuel consumption. The present invention also provides a cylinder head, which is beneficial to reduce the fuel consumption of the engine by using the above-mentioned valve. The present invention also provides an engine which uses the above-mentioned cylinder head and has low fuel consumption.

[0027] The following will clearly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com