Special anti-freezing plastic composite pipe

A technology of composite pipes and plastics, applied in the direction of pipes, rigid pipes, pipe components, etc., which can solve the problems of easy freezing, increased cost, and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

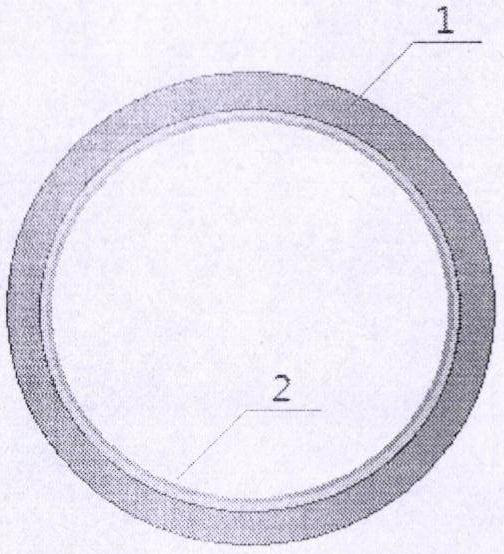

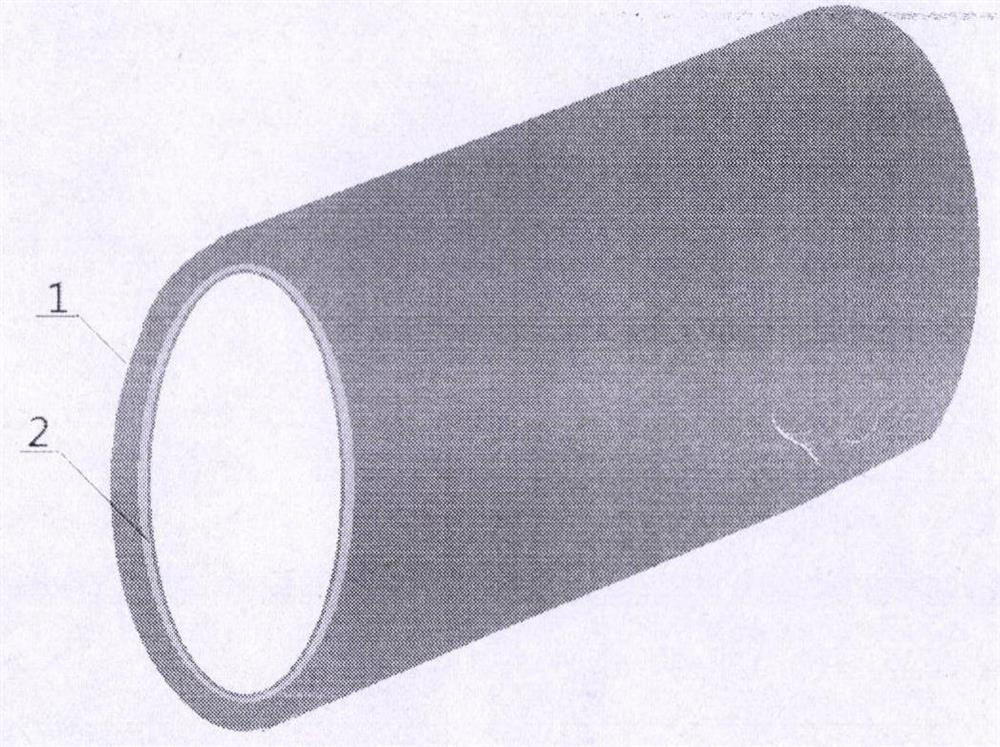

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. When the equipment is installed, the plastic hot-melt composite pipe of the required length is cut off, and the inner liner is gently expanded to the inner wall at the upper nozzle of the pipe to be tightly attached to it, and the upper expansion ring is pressed into the nozzle to make the inner lining The pipe and the hot melt pipe are integrated at the expansion ring, and then the upper nozzle is connected to the upper equipment through the thermal fuse. When the pipe is emptied, the water in the upper equipment is drained first, and then the air is passed through the expansion ring. The ventilation gap is input into the interlayer between the outer pipe wall and the inner liner, making it easier for the inner liner to shrink together. At the lower nozzle of the pipe, gently expand the inner liner to the inner wall to closely adhere to it, and then conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com