Nylon fiber

A technology of nylon fiber and fiber, which is applied in the field of nylon fiber, can solve the problems of high proportion of nylon, decrease of viscosity of copolymerized nylon, inability to obtain boiling water shrinkage, etc., and achieve the effect of high boiling water shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

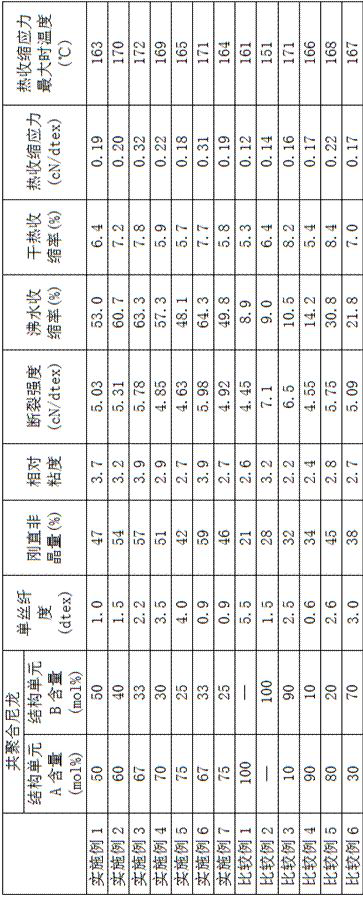

Embodiment 1

[0051] will contain the structural unit A[—NH(CH 2 ) 5 CO—]50mol% and structural unit B[—HN(CH 2 ) 6 NHCO (CH 2 ) 4 CO —] 50mol% polymer slices are dried to 300-400ppm, put into the spinning silo for spinning, the spinning temperature is 300°C, and the spinning speed is 3300m / min. After the mixed chips are melted and measured, the filaments are discharged from the spinneret, cooled and oiled, and coiled by one-step process of spinning and stretching. The stretching temperature is 28°C, the heat setting temperature is 170°C, and the elongation ratio is 1.65 times.

[0052] The monofilament fineness of the nylon fiber obtained by the above method is 1.0dtex, the breaking strength is 5.03cN / dtex, the boiling water shrinkage rate is 53.0%, the dry heat shrinkage rate is 6.4%, the thermal shrinkage stress is 0.19cN / dtex, and the temperature at the maximum thermal shrinkage stress is 163°C , the amount of rigid amorphous is 47%, and the viscosity is 3.7.

Embodiment 2

[0054] will contain the structural unit A[—NH(CH 2 ) 5 CO—]60mol% and structural unit B[—HN(CH 2 ) 6 NHCO (CH 2 ) 4 CO —] 40mol% polymer chips are dried to 300-400ppm, put into the spinning silo for spinning, the spinning temperature is 305°C, and the spinning speed is 3200m / min. After the mixed chips are melted and measured, the filaments are discharged from the spinneret, cooled and oiled, and coiled by one-step process of spinning and stretching. The stretching temperature is 20°C, the heat setting temperature is 165°C, and the elongation ratio is 1.58 times.

[0055] The monofilament fineness of the nylon fiber obtained by the above method is 1.5dtex, the breaking strength is 5.31cN / dtex, the boiling water shrinkage rate is 60.7%, the dry heat shrinkage rate is 7.2%, the thermal shrinkage stress is 0.20cN / dtex, and the temperature at the maximum thermal shrinkage stress is 170°C , the amount of rigid amorphous is 54%, and the viscosity is 3.2.

Embodiment 3

[0057] will contain the structural unit A[—NH(CH 2 ) 5 CO—]67mol% and structural unit B[—HN(CH 2 ) 6 NHCO (CH 2 ) 4 CO —] 33mol% polymer chips are dried to 300-400ppm, put into the spinning silo for spinning, the spinning temperature is 305°C, and the spinning speed is 3100m / min. After the mixed chips are melted and measured, the filaments are discharged from the spinneret, cooled and oiled, and coiled by one-step process of spinning and stretching. The stretching temperature is 20°C, the heat setting temperature is 160°C, and the elongation ratio is 1.54 times.

[0058] The monofilament fineness of the nylon fiber obtained by the above method is 2.2dtex, the breaking strength is 5.78cN / dtex, the boiling water shrinkage rate is 63.3%, the dry heat shrinkage rate is 7.8%, the thermal shrinkage stress is 0.32cN / dtex, and the temperature at the maximum thermal shrinkage stress is 172°C , the amount of rigid amorphous is 57%, and the viscosity is 3.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com