Preparation method of photocatalytic film based on Mo-doped TaN as well as product and application of photocatalytic film based on Mo-doped TaN

A photocatalytic film and photocatalytic material technology, which is applied in the field of photocatalytic film preparation, can solve the problems of difficult recycling, large influence of process factors, and difficult shape control, etc., so as to improve TaN photocatalytic activity, repeatability and stability. Good controllability and the effect of improving light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

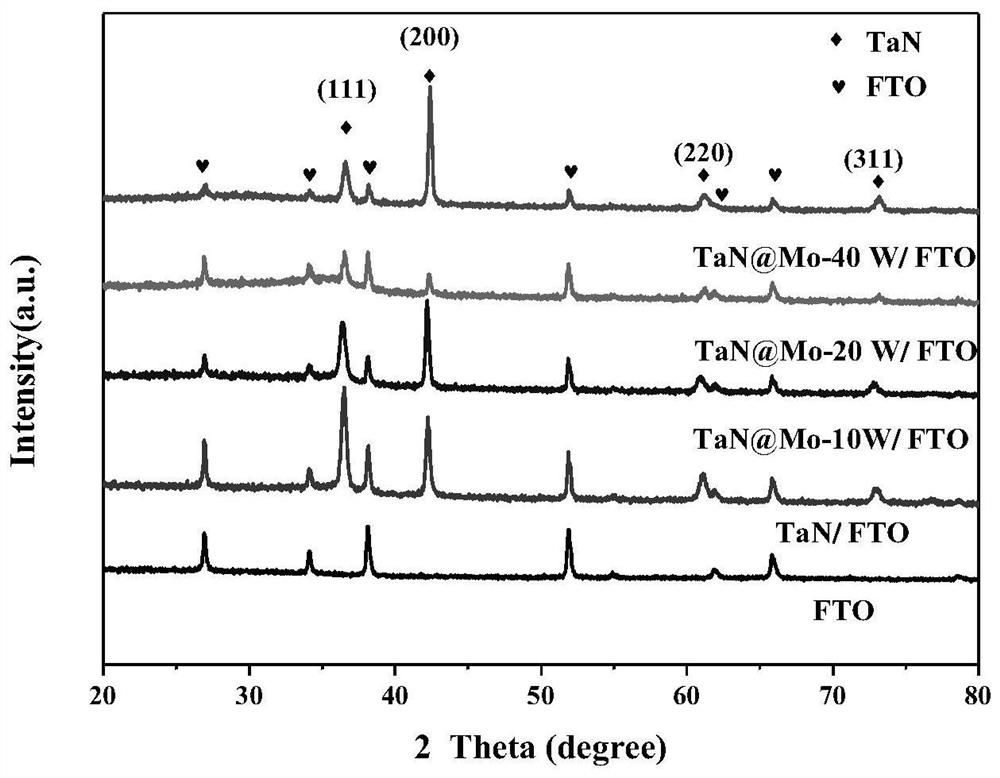

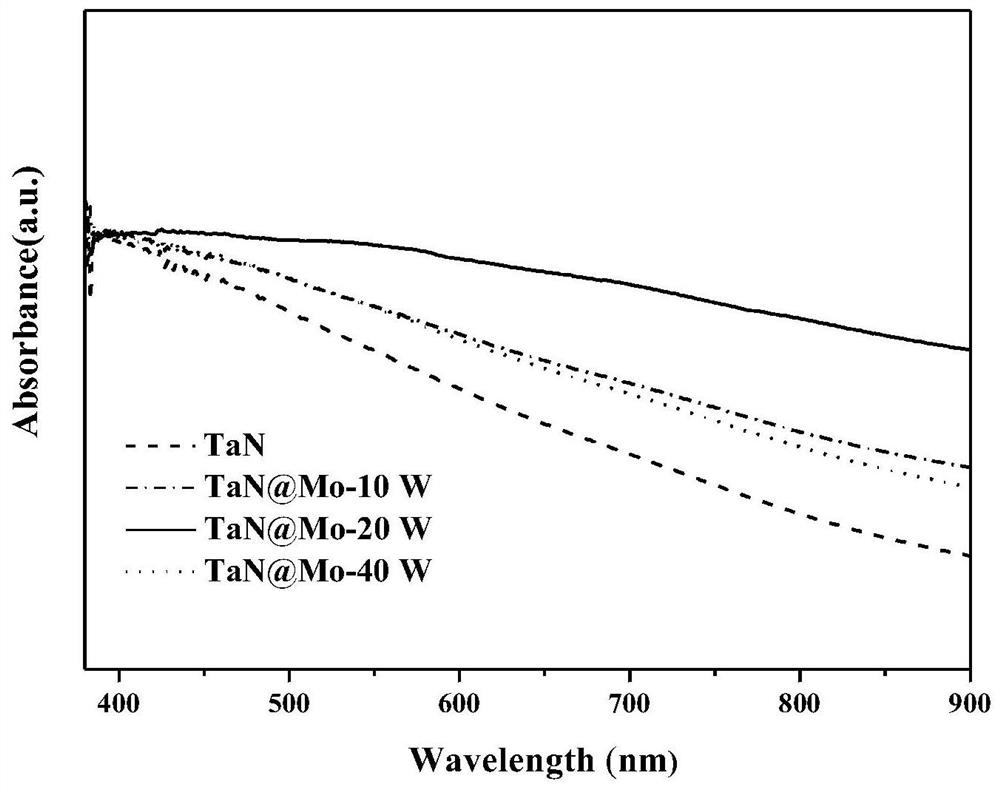

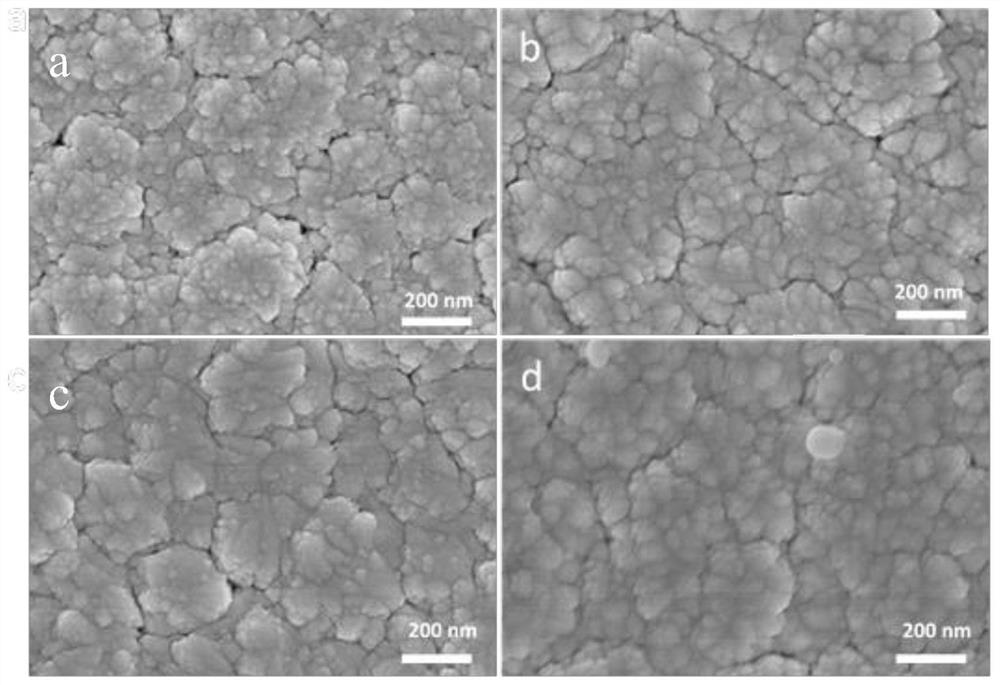

[0033] The specific process of the photocatalytic film based on Mo-doped TaN is:

[0034] a. The FTO transparent conductive film substrate was ultrasonically cleaned with acetone, ethanol and deionized water for 15 minutes respectively;

[0035] b. Dry the cleaned substrate, and use it as a substrate, put it on the substrate holder of the magnetron sputtering chamber, vacuumize the chamber and heat the substrate;

[0036] c. Using magnetron sputtering technology, argon and nitrogen with a purity of 99.999% are used as sputtering gas and reaction gas respectively under high temperature and high vacuum environment, and Mo with a thickness of about 200nm is prepared by double-target co-sputtering method Doped TaN film layer. Among them, the sputtering power of the tantalum target is 130W, and a DC sputtering source is used; the sputtering power of the molybdenum target is 10W, and a radio frequency sputtering source is used to prepare the photocatalytic film TaN@Mo-10W / FTO based...

Embodiment 2

[0039] The specific process of the photocatalytic film based on Mo-doped TaN is:

[0040] a. The FTO transparent conductive film substrate was ultrasonically cleaned with acetone, ethanol and deionized water for 15 minutes respectively;

[0041] b. Dry the cleaned substrate, and use it as a substrate, put it on the substrate holder of the magnetron sputtering chamber, vacuumize the chamber and heat the substrate;

[0042]c. Using magnetron sputtering technology, argon and nitrogen with a purity of 99.999% are used as sputtering gas and reaction gas respectively under high temperature and high vacuum environment, and Mo with a thickness of about 200nm is prepared by double-target co-sputtering method Doped TaN film layer. Among them, the sputtering power of the tantalum target is 130W, and a DC sputtering source is used; the sputtering power of the molybdenum target is 20W, and a radio frequency sputtering source is used to prepare the photocatalytic film TaN@Mo-20W / FTO based ...

Embodiment 3

[0045] The photocatalytic film based on Mo-doped TaN of the present invention, its specific process is:

[0046] a. The FTO transparent conductive film substrate was ultrasonically cleaned with acetone, ethanol and deionized water for 15 minutes respectively;

[0047] b. Dry the cleaned substrate, and use it as a substrate, put it on the substrate holder of the magnetron sputtering chamber, vacuumize the chamber and heat the substrate;

[0048] c. Using magnetron sputtering technology, argon and nitrogen with a purity of 99.999% are used as sputtering gas and reaction gas respectively under high temperature and high vacuum environment, and Mo with a thickness of about 200nm is prepared by double-target co-sputtering method Doped TaN film layer. Among them, the sputtering power of the tantalum target was 130W, and a DC sputtering source was used; the sputtering power of the molybdenum target was 40W, and a radio frequency sputtering source was used to prepare the photocatalyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com