Method for improving homogenizing efficiency of 7000 series aluminum alloy cast ingots

An aluminum alloy casting ingot and aluminum alloy technology, which is applied in the field of metal materials, can solve problems such as increasing production costs, prolonging heat preservation time, and cracking during thermal processing, and achieves the effects of avoiding overburning, shortening time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0033] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

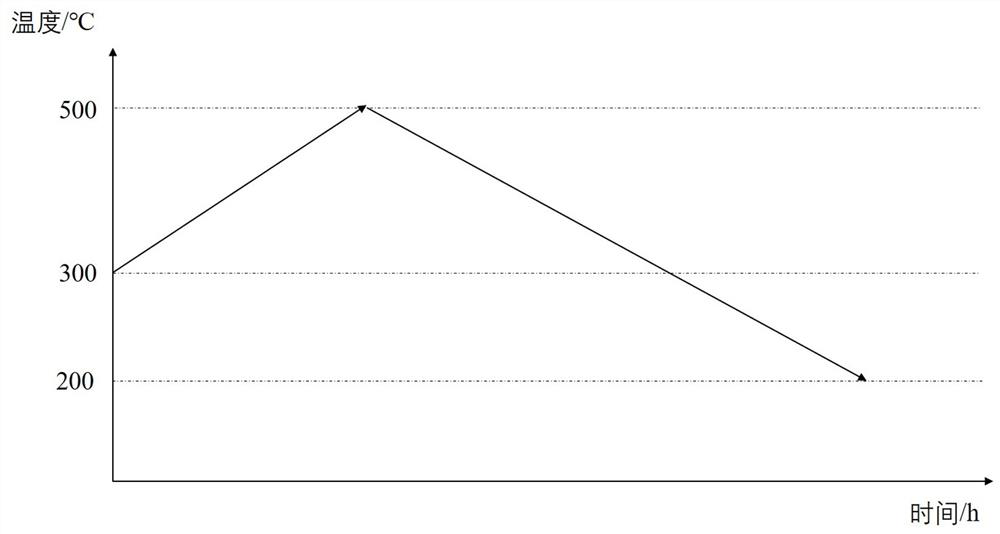

[0035]Select a 7085 aluminum alloy flat ingot with a thickness of 300mm. When the temperature of the heat treatment furnace reaches 300°C, put it into the ingot, and linearly raise the temperature to 500°C at a heating rate of 20°C / h, and then linearly increase the temperature at a cooling rate of 20°C / h. Cool down to 200°C, cool down to 200°C and take out of the furnace, air cool to room temperature, and the total time of the ingot in the heat treatment furnace is 25h.

Embodiment 2

[0039] Select a 7050 aluminum alloy flat ingot with a thickness of 520mm. When the temperature of the heat treatment furnace reaches 300°C, put it into the ingot, and linearly raise the temperature to 500°C at a heating rate of 10°C / h, and then linearly increase the temperature at a cooling rate of 15°C / h. Cool down to 200°C, cool down to 200°C and leave the furnace, air cool to room temperature, and the total time of the ingot in the heat treatment furnace is 40h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com