Dimethyl carbonate azeotropic solvent composition, preparation method thereof, automobile low-temperature stoving varnish formula and application

A solvent composition, dimethyl carbonate technology, applied in the directions of detergent compositions, non-surface-active detergent compositions, cleaning composition solvents, etc., can solve the problem of paint film peeling, white skin peeling, and wrinkles on the surface of the paint film. or corrugation, etc., to achieve the effect of smooth paint film, good leveling and uniform color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a method for preparing the azeotropic solvent composition as described in any one of the above technical solutions, comprising the steps of:

[0061] 1) After mixing dimethyl carbonate and two or more compounds, an azeotropic solvent composition is obtained.

[0062] In the preparation method of the present invention, the specific preferred scheme of the raw material and the preferred numerical value of the number of added parts are consistent with the specific preferred scheme of the components in the aforementioned azeotropic solvent composition and the preferred numerical value of the added number of parts. This will not repeat them one by one.

[0063] In principle, the present invention has no particular limitation on the specific method and parameters of the mixing, and those skilled in the art can select and adjust according to production conditions, usage conditions and performance requirements. In order to better improve the ...

Embodiment 1

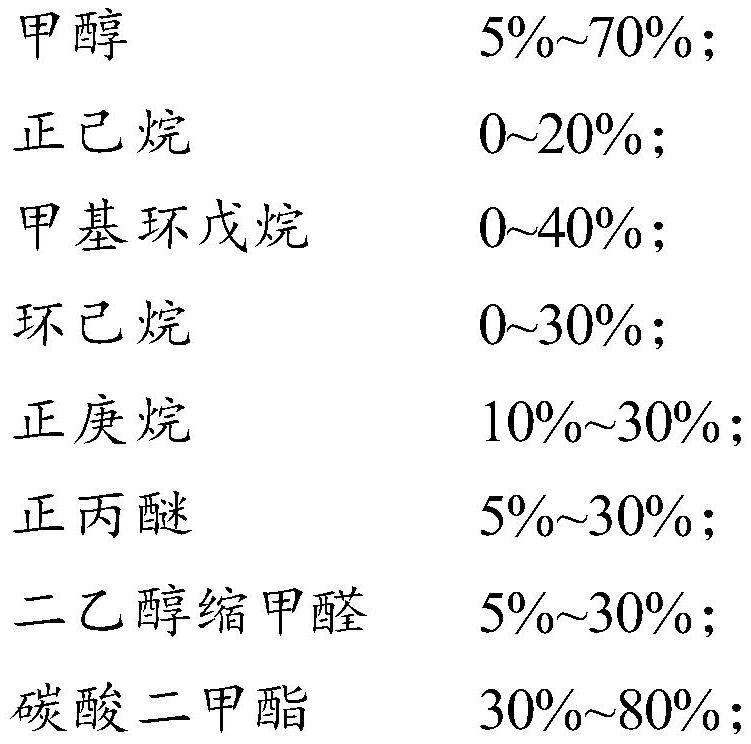

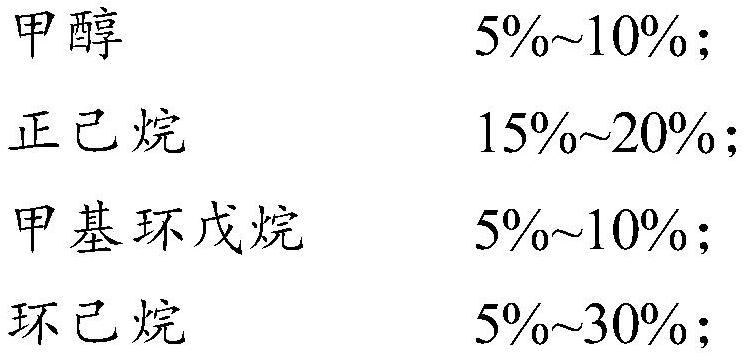

[0077] The azeotropic solvent composition for automotive low-temperature baking paint consists of the following component raw materials in mass percentages:

[0078] 5% methanol, 15% n-hexane, 5% methylcyclopentane, 5% cyclohexane, 5% diethanol formal, 15% n-heptane, 5% n-propyl ether, 45% dimethyl carbonate

[0079] Production method: Put the components in the steps into the stirring tank in sequence, dimethyl carbonate, n-propyl ether, n-heptane, cyclohexane, methylcyclopentane, n-hexane, and methanol, and Stir evenly in the stirred tank, the reactant has no stratification phenomenon, and is clear and transparent, without suspended matter and mechanical impurities. After standing for a period of time, it is the same as when it was just stirred uniformly. Low temperature baking solvent finished product.

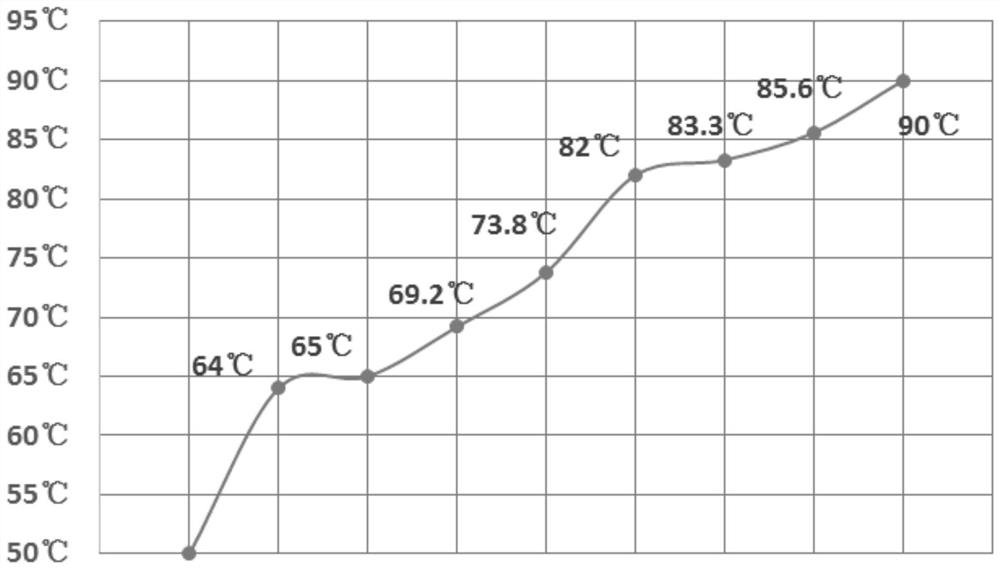

[0080] Performance testing was performed on the azeotropic solvent composition for low-temperature automotive paints prepared in Example 1 of the present invention.

[008...

Embodiment 2

[0089] The azeotropic solvent composition for automotive low-temperature baking paint consists of the following component raw materials in mass percentages:

[0090] 5% methanol, 5% n-hexane, 5% methylcyclopentane, 5% cyclohexane, 5% diethanol formal, 15% n-heptane, 5% n-propyl ether, 55% dimethyl carbonate

[0091] Production method: Put the components in the steps into the stirring tank in sequence, dimethyl carbonate, n-propyl ether, n-heptane, cyclohexane, methylcyclopentane, n-hexane, and methanol, and Stir evenly in the stirred tank, the reactant has no stratification phenomenon, and is clear and transparent, without suspended matter and mechanical impurities. After standing for a period of time, it is the same as when it was just stirred uniformly. Low temperature baking solvent finished product.

[0092] Performance testing was performed on the azeotropic solvent composition for automotive low-temperature baking varnish prepared in Example 2 of the present invention. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| azeotropic temperature | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com