Multi-copy processing production line with modularized vertical continuous online gold stamping mechanisms

A modular, production line technology, applied in printing presses, rotary presses, printing and other directions, can solve the waste of labor and site turnover and cost timeliness, it is difficult to achieve multiple online molding of products at one time, and it is impossible to use hot stamping once for office work. Forming and other problems, to achieve the effect of reducing the level of technicians, improving timeliness, and reducing site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. The following description of at least one exemplary embodiment is merely illustrative in nature and is in no way intended to limit the invention, its application, or uses.

[0035] In order to keep the following description of the embodiments of the present invention clear and concise, the present invention omits detailed descriptions of well-known functions and well-known components.

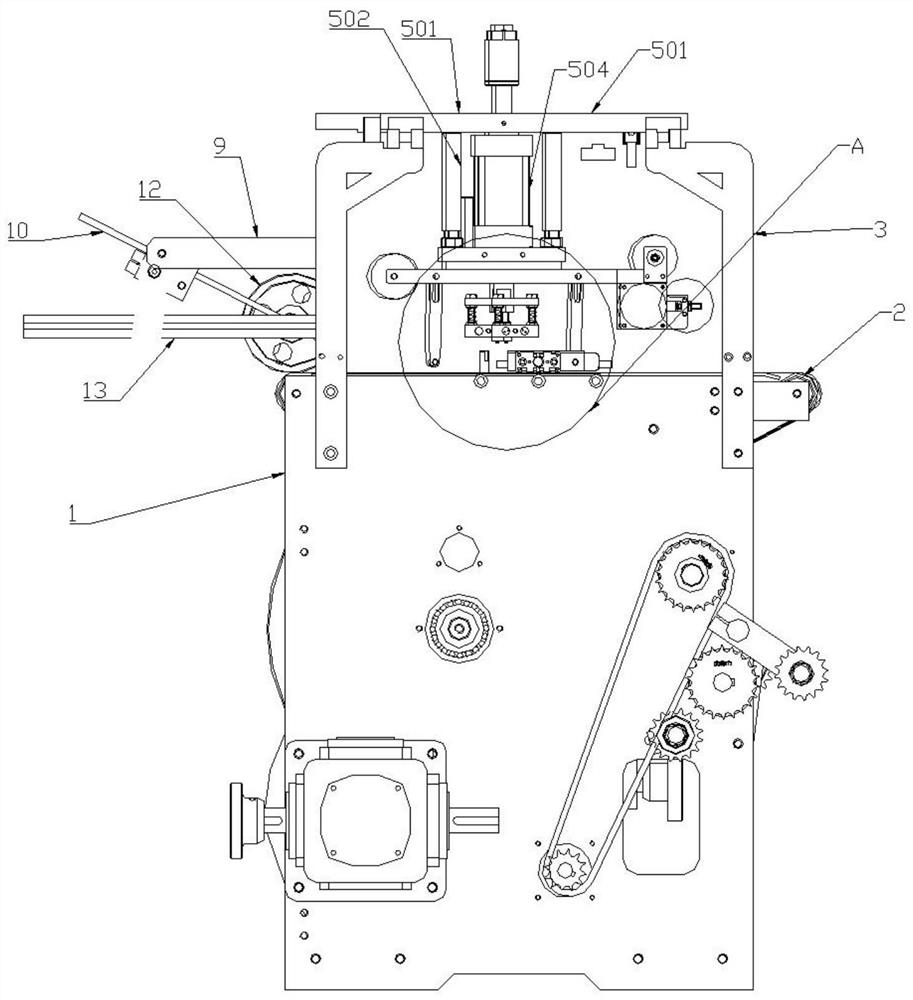

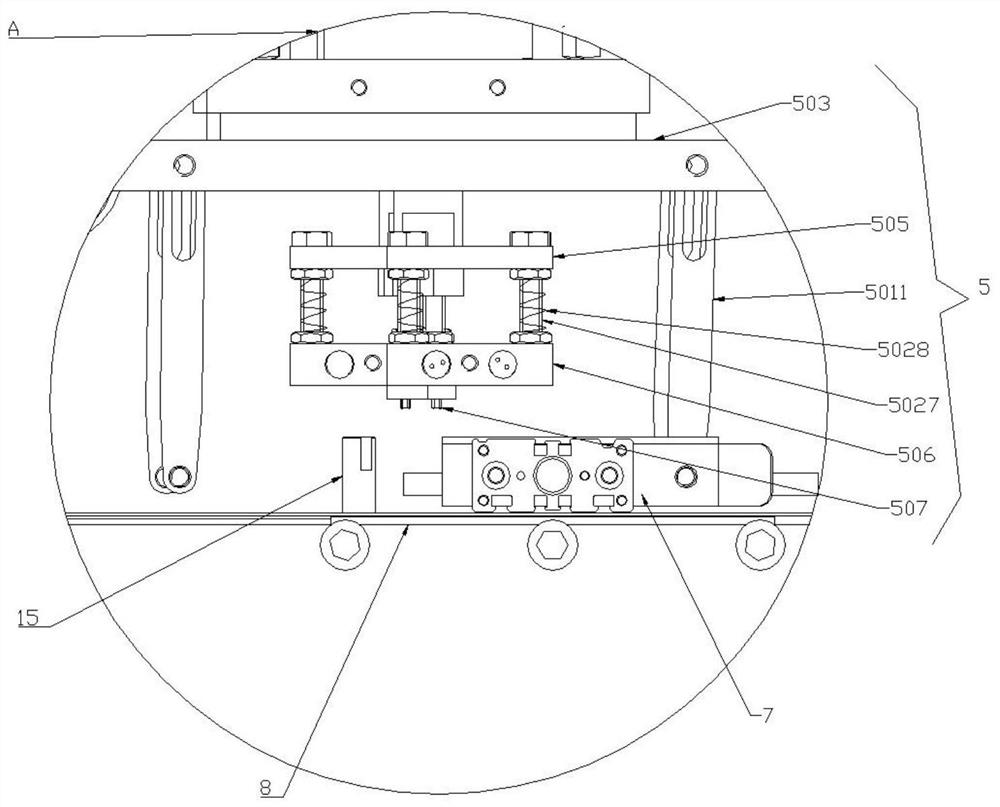

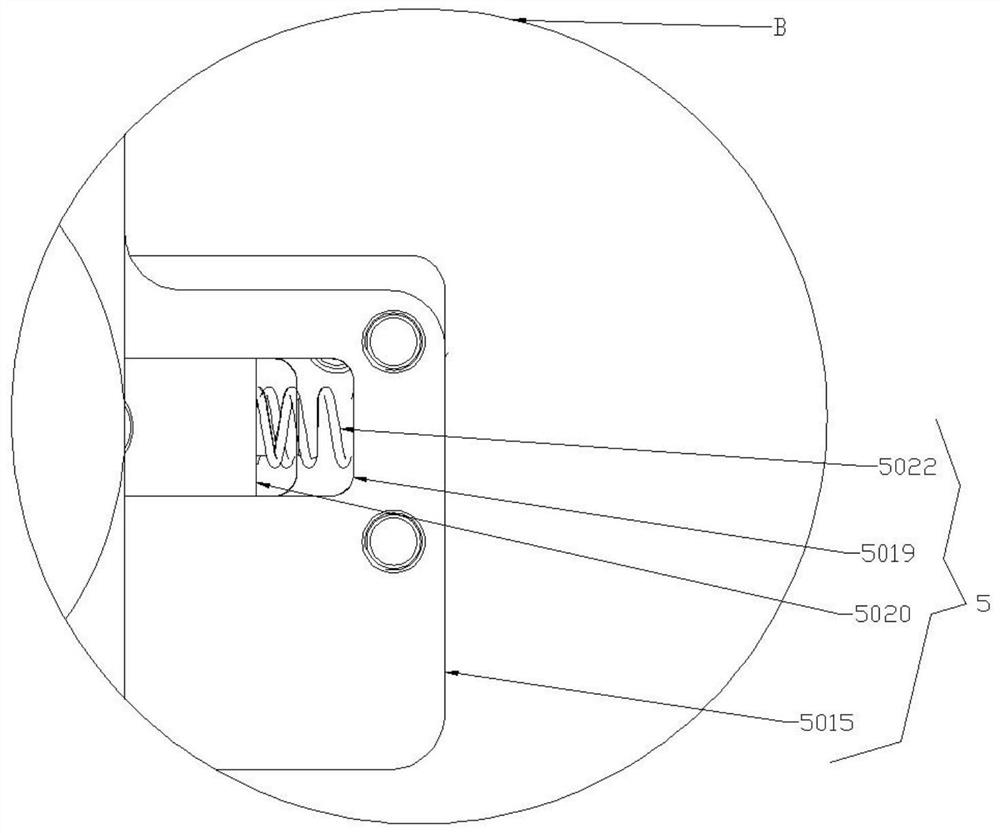

[0036] see Figure 1-10 As shown, in this embodiment, a multi-part processing production line with a modular vertical continuous on-line hot stamping mechanism is provided, including: a workbench 1, a conveyor belt 2 is installed on the upper side of the workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com