An online detection system for the surface quality of aluminum alloy thin-walled parts during milling

A surface quality and detection system technology, applied in metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of difficult detection, missed detection of defective products, poor detection effect, etc., and achieve the effect of improving the detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

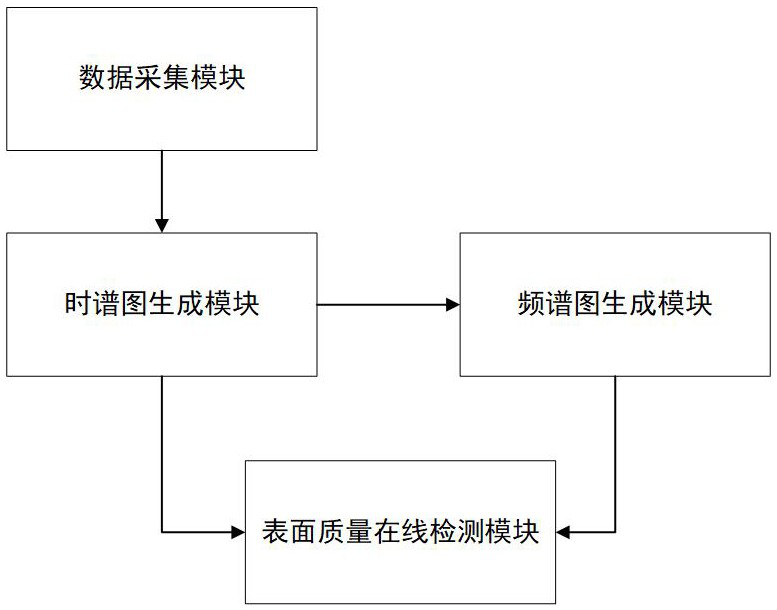

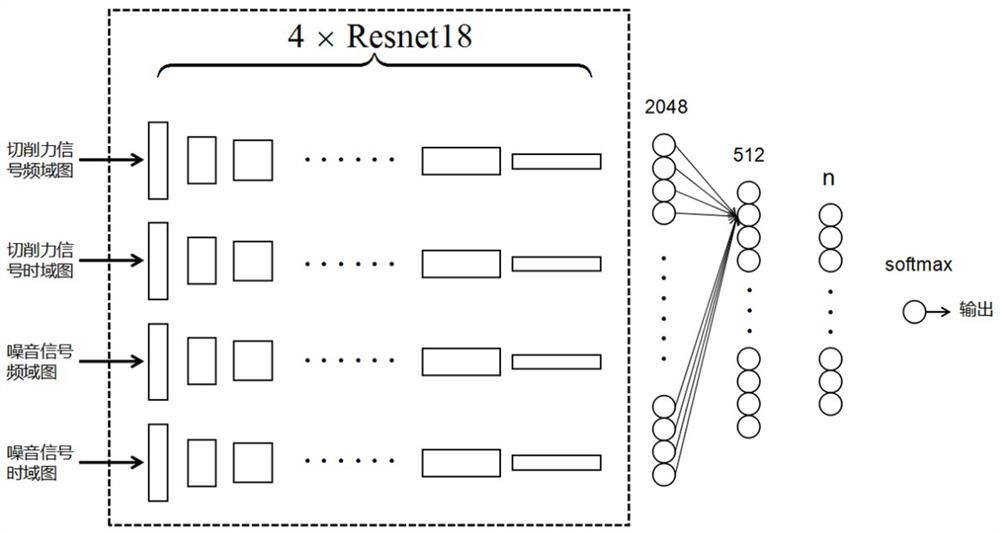

[0034] Such as figure 1 As shown, an online surface quality detection system for the milling process of aluminum alloy thin-walled parts provided by this embodiment includes a data acquisition module, a time-spectrum generation module, a spectrum generation module and an online surface quality detection module.

[0035] The data acquisition module is used to collect cutting force signals and noise signals in the milling process of aluminum alloy thin-walled parts; specifically, a cutting force tester is used to collect cutting force signals, an audio collector is used to collect noise signals, and the cutting force tester Both the cutting force tester and the audio collector are installed on the milling machine tool and can collect corresponding signals. According to the equipment installation on site, the cutting force tester and the audio collector are connected to the industrial computer in the field through the data transmission line. A software program that realizes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com