Metal frame structure and manufacturing method thereof

A technology of metal frame and manufacturing method, applied in the direction of building components, etc., can solve the problems of complex manufacturing process, large environmental pollution, low production efficiency, etc., and achieve the effect of high material cost, pollution reduction, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

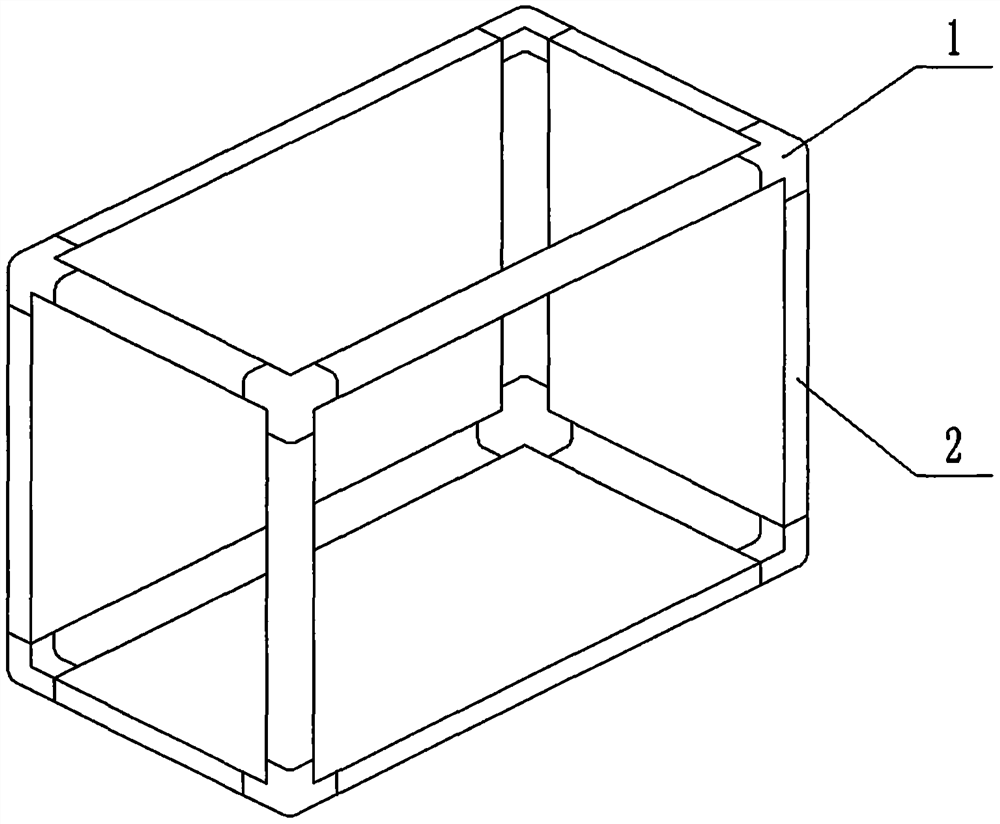

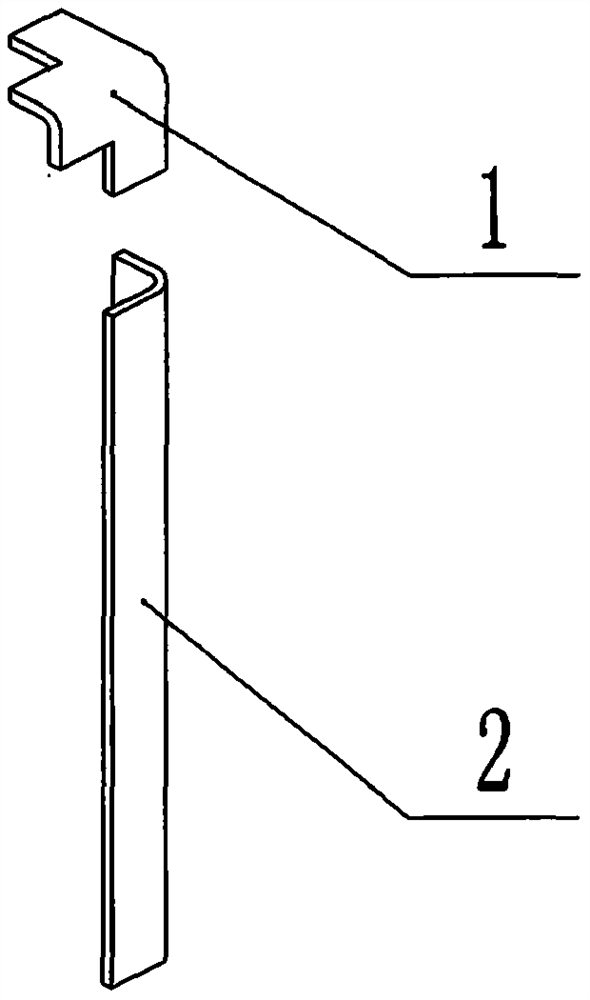

[0030] Such as Figure 1 to Figure 2 As shown, the shape of the present invention is a cuboid frame formed by butt joints of strip frame beams, including four upper frame beams, four lower frame beams and four vertical frame beams. The metal frame structure is assembled by butt joints of eight corner joints 1 and frame beams 2. The corner joints 1 are assembled at eight corner positions of the cuboid frame, and one corner joint 1 is respectively connected to adjacent and perpendicular Three frame beams 2 are fixedly connected. Vertex joint 1 is precision pressed or precision cast, with a vertice and three mutually perpendicular vertices, and three mutually perpendicular edges connected to the vertices, and the vertices and edges are arcs transition. The corner joint 1 is provided with an interface matched with the end of the frame beam 2 at the end of each edge. The corner joint 1 and the frame beam 2 are connected by inner surface welding. The frame beam 2 is a metal stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com