A forming method for realizing microstructure refinement of near β-type titanium alloy thin-walled structural parts

A technology of thin-walled structural parts and titanium alloys, applied in metal processing equipment and other directions, can solve the problems of difficult microstructure control and difficult control of forming stability, and achieve the effects of shortened development cycle, fine grain size and efficient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

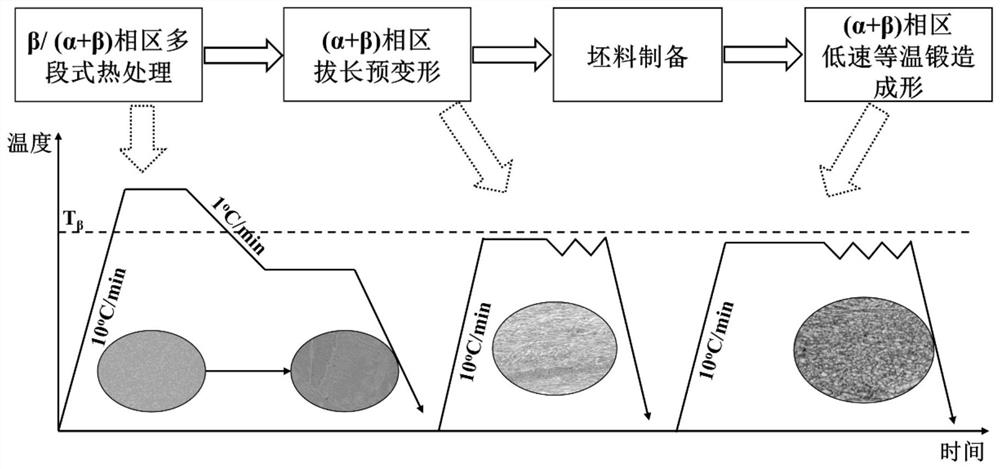

[0041] This embodiment is a forming method for realizing the microstructure of TB6 near β-type titanium alloy structural parts with wall thickness less than 0.8mm. The specific process is:

[0042] Step 1, multi-stage heat treatment in β / (α+β) phase region:

[0043] The TB6 titanium alloy bar with Φ90mm specification is used, and the phase transition temperature is 805°C. The TB6 titanium alloy bar was put into a vacuum heat treatment furnace for multi-stage heat treatment to obtain a lamellar structure. The cooling rate of the bar is furnace-cooled to 750 ° C, and the temperature is continued for 40 minutes; after the heat preservation, the bar is furnace-cooled to room temperature.

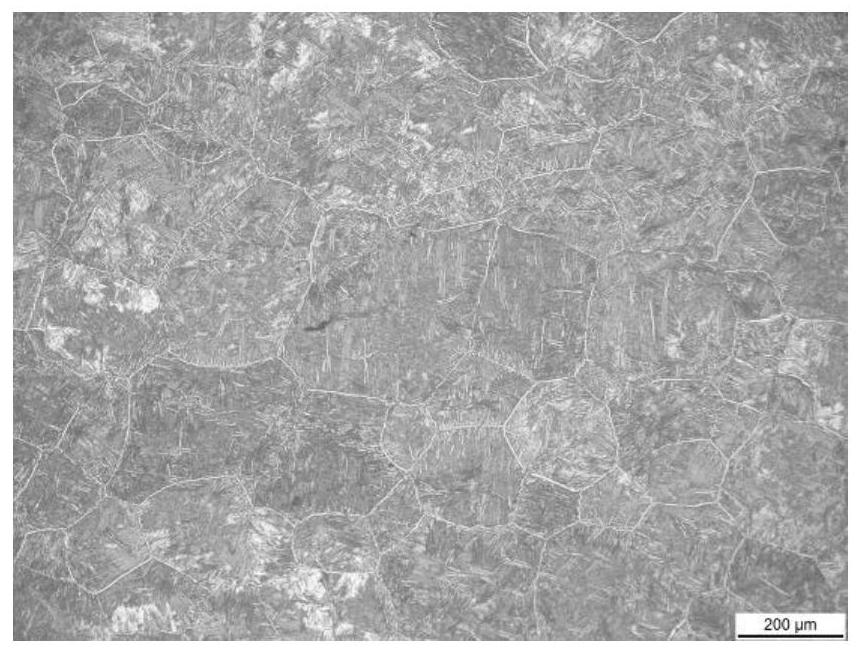

[0044] A TB6 titanium alloy bar that has undergone multi-stage heat treatment is obtained. Its microstructure is figure 2 As shown, the average β grain size is 213 μm, the average grain boundary α size is 2.5 μm, and the average thickness of the α sheet inside the β grain is 1 μm.

[0045] ...

Embodiment 2

[0061] This embodiment is a forming method for realizing the microstructure of Ti-55531 near β-type titanium alloy structural parts with a wall thickness of less than 0.8mm. The specific process is:

[0062] Step 1, multi-stage heat treatment in β / (α+β) phase region:

[0063] Ti-55531 titanium alloy bar with Φ90mm specification is used, and the phase transition temperature is 845℃. The Ti55531 titanium alloy bar was put into a vacuum heat treatment furnace for multi-stage heat treatment to obtain a lamellar structure. The cooling rate of the bar is furnace-cooled to 650 ℃, and the temperature is kept for 50 minutes; after the heat preservation, the bar is furnace-cooled to room temperature.

[0064] A Ti-55531 titanium alloy bar that has undergone multi-stage heat treatment is obtained. Its microstructure is Figure 5 As shown, the average β grain size is 225 μm, the average grain boundary α size is 2 μm, and the thickness of the α sheet inside the β grain is 0.8 μm.

[00...

Embodiment 3

[0081] This embodiment is a forming method for realizing the microstructure of Ti-7333 metastable β-type titanium alloy structural parts with wall thickness less than 0.8mm. The specific process is:

[0082] Step 1, multi-stage heat treatment in β / (α+β) phase region:

[0083] Ti-7333 titanium alloy bar with Φ90mm specification is used, and the phase transition temperature is 850℃. The Ti-7333 titanium alloy bar was put into a vacuum heat treatment furnace for multi-stage heat treatment to obtain a lamellar structure. The bar was furnace-cooled to 700°C at a cooling rate of min, and kept for 30 minutes under this condition; after the heat preservation, the bar was furnace-cooled to room temperature.

[0084] A Ti-7333 titanium alloy bar that has undergone multi-stage heat treatment is obtained. Its microstructure is Figure 7 As shown in the figure, the average β grain size is 230 μm, the average grain boundary α size is 2.1 μm, and the average thickness of the α sheet insid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com