Body position frame for hip replacement and manufacturing method of body position frame

A technology for hip replacement and manufacturing method, applied in the directions of additive manufacturing, manufacturing tools, manufacturing auxiliary devices, etc., can solve the problems of limited adaptability of patients, inability to use for a long time, poor effect of auxiliary body position frame, etc., to eliminate discomfort, The effect of saving waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

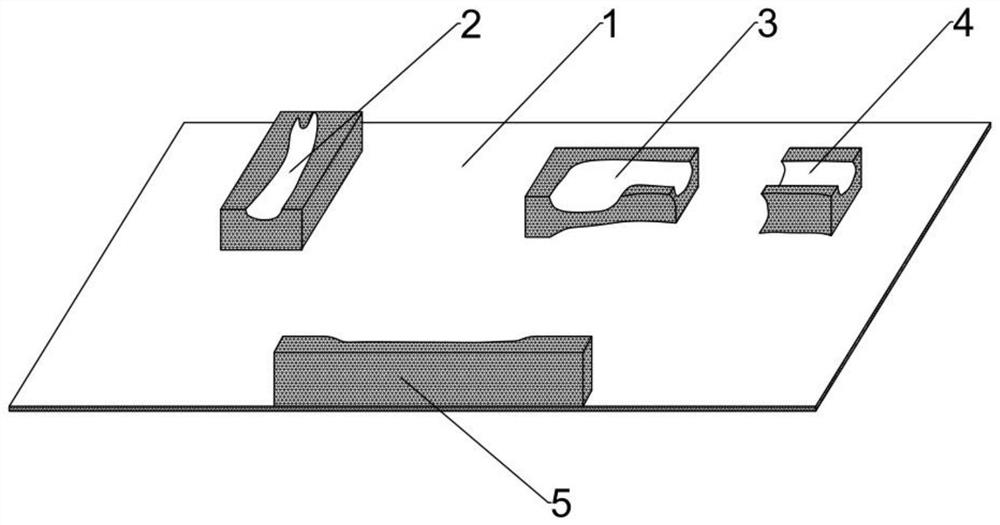

[0032] see figure 1 , figure 1 It is a structural schematic diagram of the posture frame for hip joint replacement in Example 1 of the present invention. The body posture frame for hip replacement in this embodiment includes a flexible base 1 with a width smaller than that of an operating bed and a hospital bed and protruding from the flexible base. 1 A plurality of bionic support modules on the upper surface, the upper surface and / or side wall of the bionic support modules are manufactured with bionic structures, and the bionic structures are processed according to the patient's standard body position information.

[0033] Specifically, the above-mentioned posture frame for hip joint replacement, the plurality of bionic support modules are used to support the standard lateral position, which includes an upper limb support module 2 and a back support module 5, and the upper limb support module 2 An upper limb bionic structure is manufactured on the upper surface, and a back b...

Embodiment 2

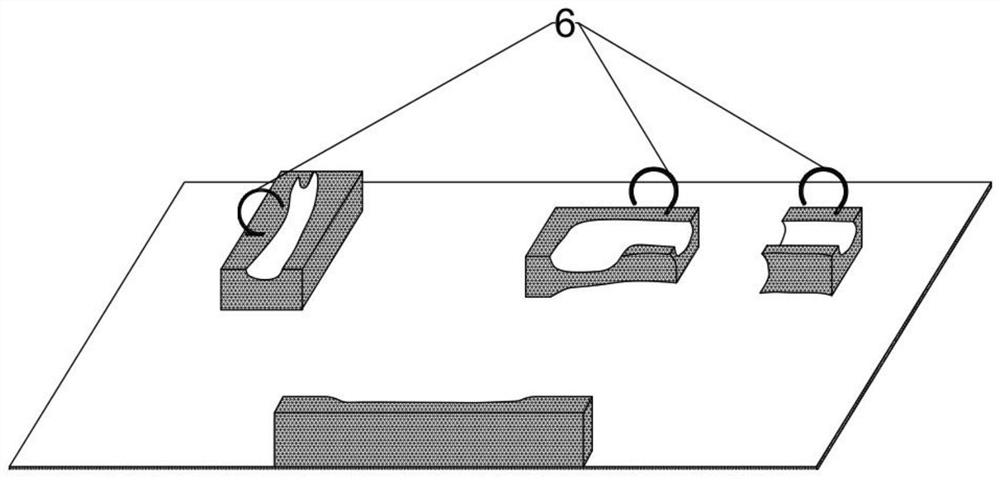

[0044] figure 2 It is the schematic diagram of the body position frame for hip replacement in this embodiment, and its scheme is actually a further improvement of the body position frame for hip replacement in Example 1. In this embodiment, in order to better restrain the patient's body position, The upper limb support module 2, the knee joint support module 3, and the calf or ankle support module 4 are all equipped with straps 6, which are used to assist in restraining human limbs.

[0045] The strap 6 in this embodiment is installed on the posture frame after the 3D printing is completed.

Embodiment 3

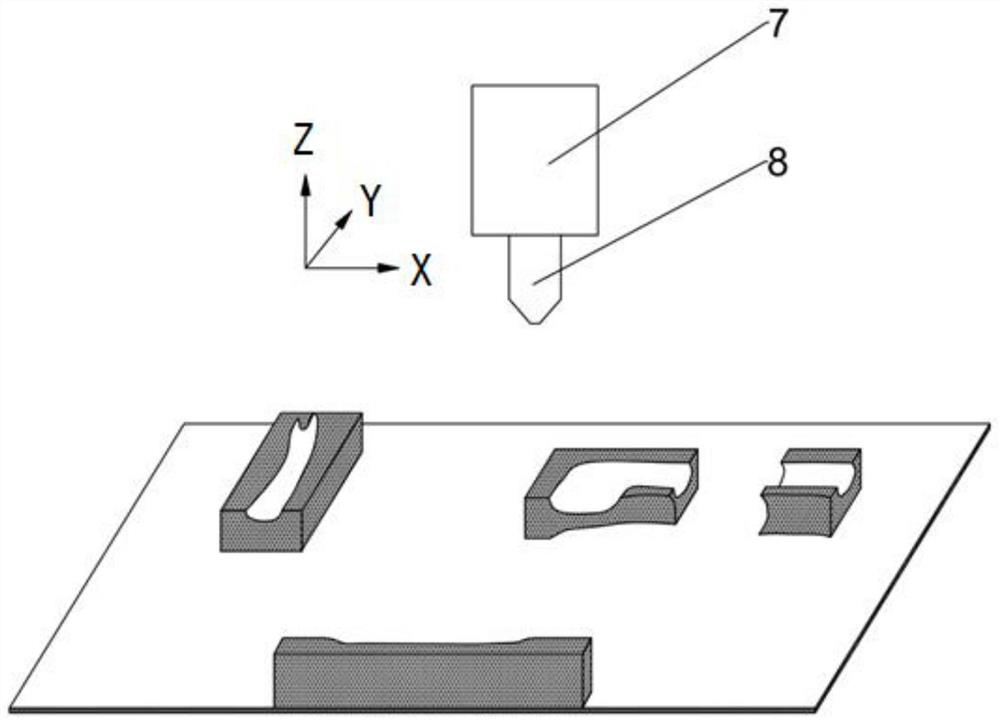

[0047] This embodiment is another design for the solution of growing multiple bionic support modules on the upper surface of the flexible substrate 1 by means of 3D printing in Example 1. Since FDM printing itself needs to design a substrate material, this solution directly select the existing flexible substrate 1 made of flexible breathable material as the printed substrate material, in this case, the process of printing the flexible substrate 1 layer by layer can be omitted in step 4, and it is not necessary in step 2 Add the 3D features of the flexible substrate 1 to the 3D digital model, where the flexible substrate 1 directly becomes the growth basis of the bionic support module. In this case, the material of the flexible substrate 1 may be different from the material of the bionic support module, but as long as The material of the flexible substrate 1 and the biomimetic support module can be easily fused (most commonly used polymer materials can be realized), which provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com