On-site detection device for high-elasticity rubber asphalt composite crushed stone seal

A technology of rubber asphalt and gravel sealing layer, which can be used in measuring devices, sampling devices, and mechanical devices, etc., can solve problems such as deficiencies, and achieve the effect of protecting functionality, wide application range, and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

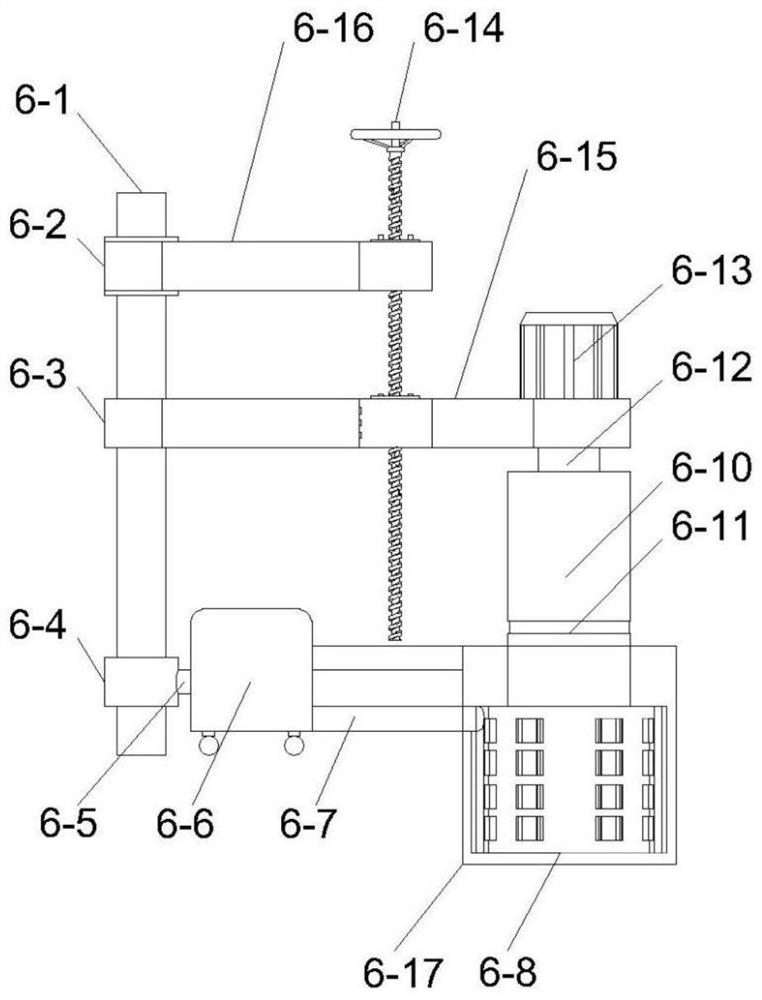

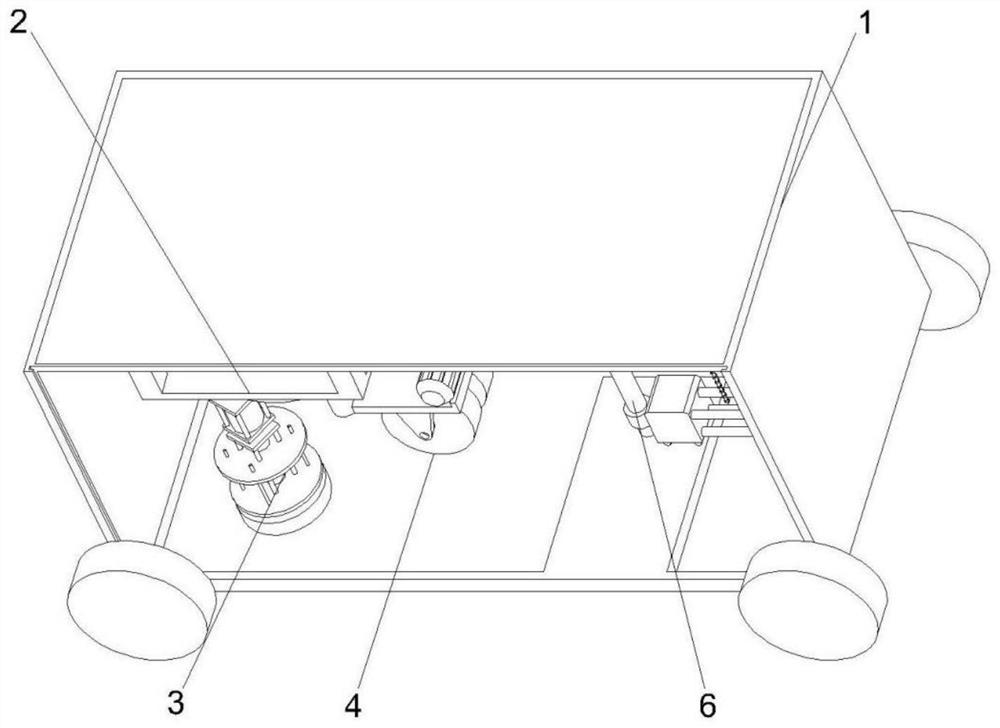

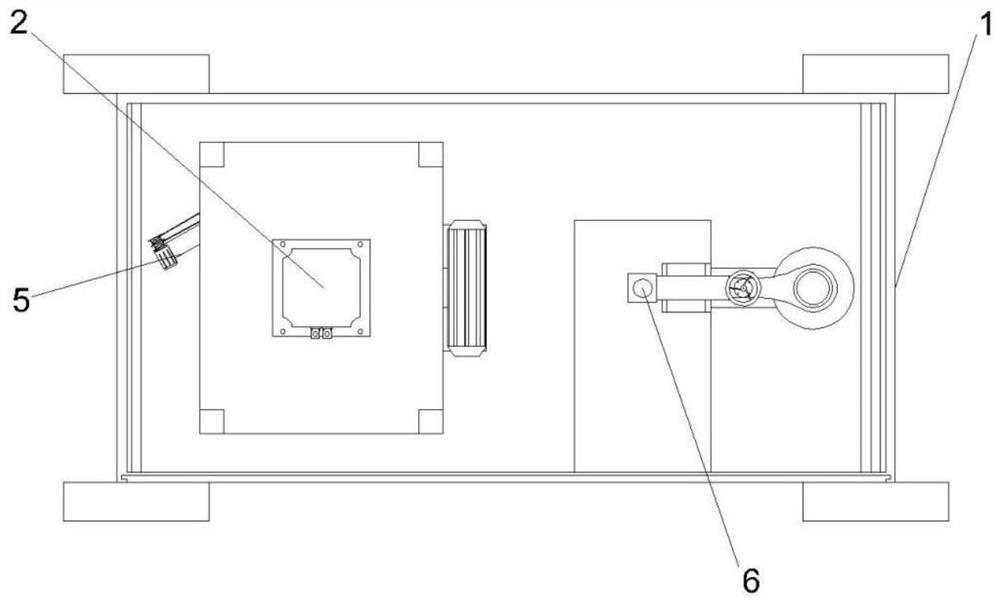

[0052] refer to Figure 1-16 , an on-site detection device for high-elastic rubber asphalt composite gravel seals, including a car body 1, an electric shaft 2, a water seepage meter 3, a rolling device 4, an improved pendulum friction meter 5 and a drill core sampling device 6, the electric first The rotating shaft 2, the water seepage meter 3, the rolling device 4, the improved pendulum friction meter 5 and the drill core sampling device 6 are located inside the car body 1, the electric first rotating shaft 2-32 is installed on the top of the car body 1, and the rolling device 4, The improved pendulum friction meter 5 and the water seepage meter 3 are installed at an angle of 120° around the electric rotating shaft 2, and the drill core sampling device 6 is located on the other side of the car body 1;

[0053] The improved pendulum tribometer 5 includes a pressure sensor 5-1, a first motor 5-2, a rope bucket 5-3, an improved pendulum tribometer base 5-4, a pendulum 5-5, an ex...

Embodiment 2

[0062] Such as Figure 1-16 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the car body 1 includes a box body 1-1, a road wheel 1-2, a first wheel shaft 1-3 and a load plate 1-4, and the box body 1-1 It is a cuboid, hollow inside, openable on the front, and an open structure at the bottom. Two pairs of walking wheels 1-2 are installed on both ends of the box body 1-1 through the first wheel shaft 1-3, and the bearing plate 1-4 is installed on the box body. Body 1-1 bottom.

[0063] In this embodiment, the setting of the walking wheels 1-2 can make the detection device more portable, and the front of the box body 1-1 is closed during transportation to protect the instrument, and can be opened during use to allow the operator to operate the instrument.

Embodiment 3

[0065] Such as Figure 1-16 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the electric rotating shaft 2 includes a servo motor 2-1, a suspension 2-2, a first rotating shaft 2-3, a first fixing sleeve 2-4, a sliding bearing Ring 2-5, slide bar 2-6 and lifting cylinder 2-7, servo motor 2-1 is installed on the suspension 2-2, the output end is connected to the first rotating shaft 2-3, suspension 2-2 is installed on the vehicle The top of the body 1, the second fixed sleeve 6-2 on the first rotating shaft 2-3, there are three sliding rods 2-6 connected around the first fixed sleeve 2-4 in a divergent manner, and the sliding rods 2-6 are in the Sliding on the bearing ring 2-5, a lifting cylinder 2-7 is installed at the bottom of each sliding rod 2-6, and rolling devices are respectively installed at the output ends of the three lifting cylinders 2-7 4. Improved pendulum friction instrument 5 and water seepage meter 3.

[0066] In this embodiment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com