Large vertical flue gas, air and pulverized coal pipeline array type flow measuring device

A flow measurement device and pulverized coal pipeline technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve problems such as frequent failures, complex design, manual dust removal, etc. Ash and clogging, solving measurement problems, and solving the effect of powder-laden airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

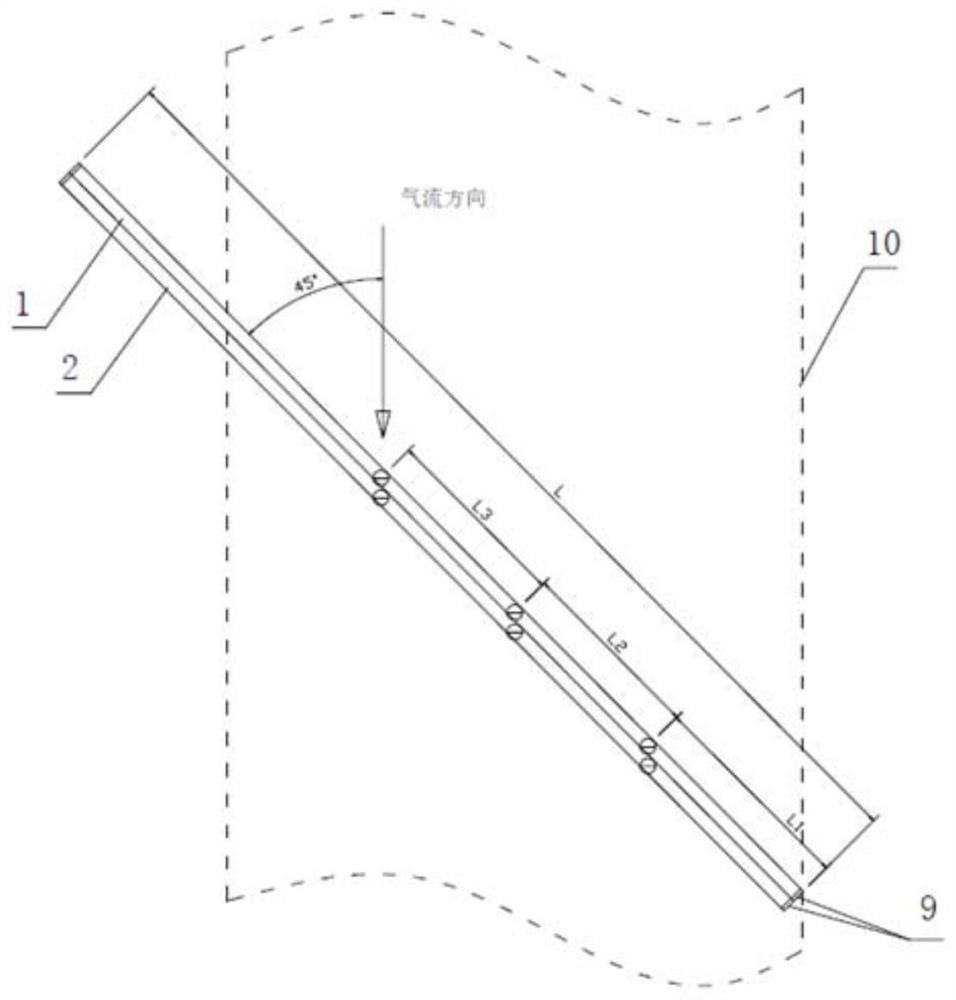

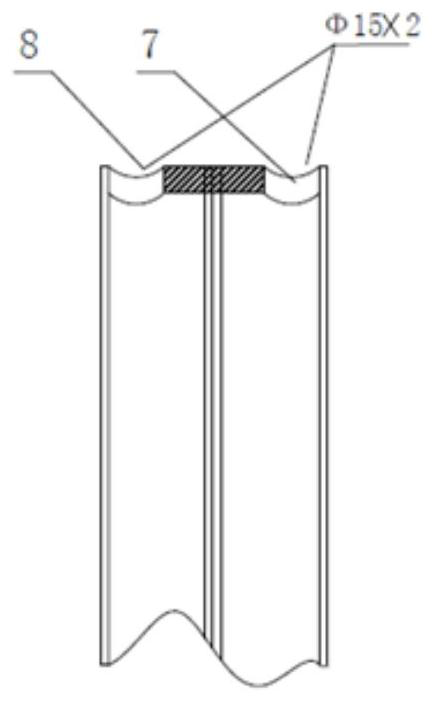

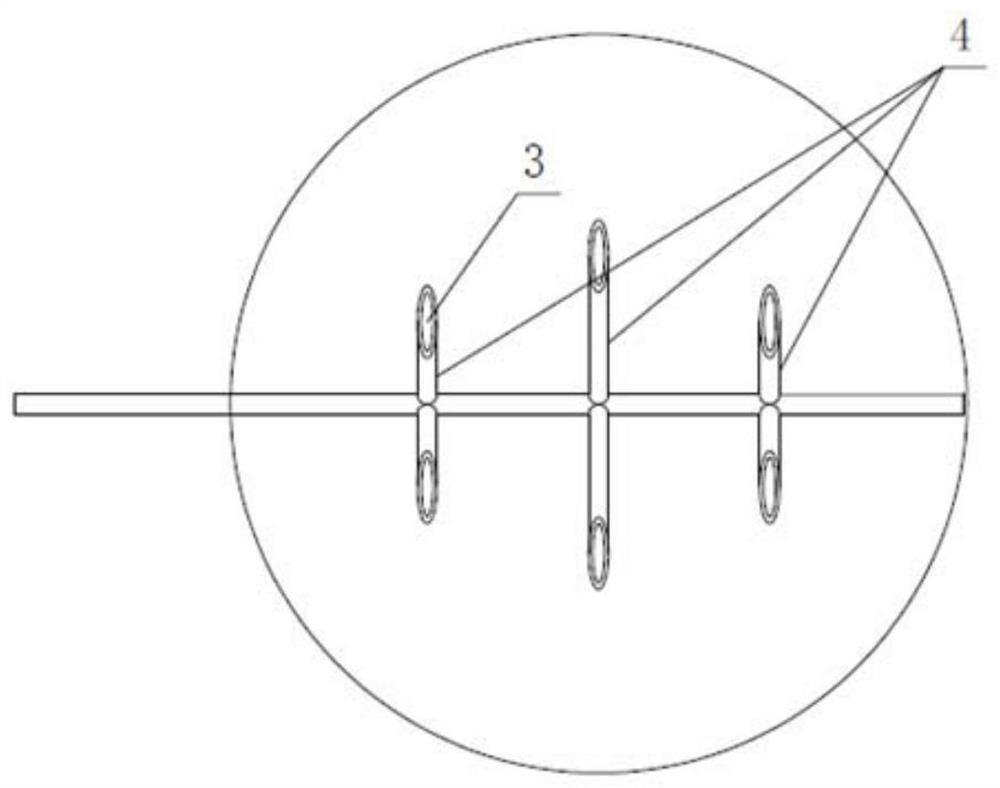

[0021] refer to Figure 1 to Figure 4 , the large-scale vertical flue gas pulverized coal pipeline array flow measuring device according to the present invention includes a dynamic pressure expansion buffer pipe 1, a static pressure expansion buffer pipe 2, a wedge type dynamic pressure sensor 3, a parallel static pressure sensor 4, a dynamic pressure transmission Pressure pipe 5, static pressure transmission pipe 6, dynamic pressure sampling hole 7, static pressure sampling hole 8 and ash release sealing plug 9; the front end of dynamic pressure expansion buffer pipe 1 and the upper end of static pressure expansion buffer pipe 2 are obliquely inserted into In the smoke wind pulverized coal pipeline 10, the lower end of the dynamic pressure expansion buffer pipe 1 and the lower end of the static pressure expansion buffer pipe 2 are closed, and each wedge type dynamic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com