Acoustic fluid micro pump based on micro electro mechanical technology

A micro-electromechanical and micro-pump technology, applied in the direction of pumps, mechanical equipment, machines/engines, etc., can solve the problems of limited application, additional products, unsustainability, etc., to achieve a wide range of applications, overcome complex structures, and efficiently pump Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

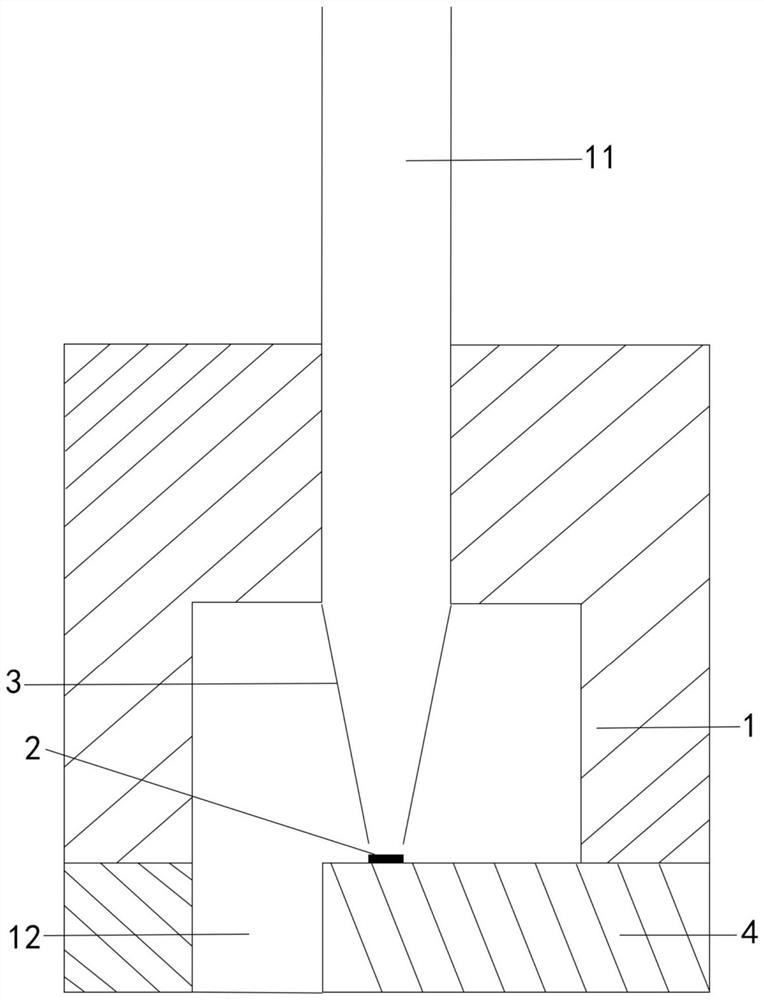

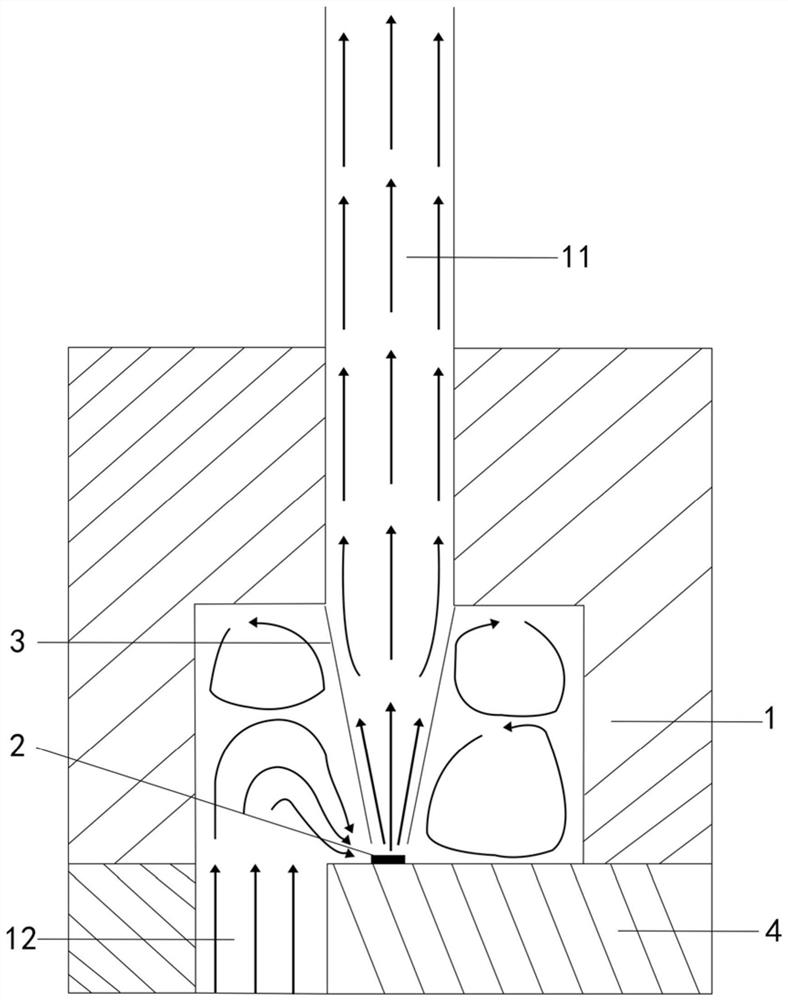

[0027] The present invention provides an acoustic fluid micropump based on microelectromechanical technology, including:

[0028] The pump chamber can be used for sample fixation and storage. There is an opening on the top of the cavity for a hard pipe to be inserted as an outlet, and an opening at the bottom of the cavity can be used as an inlet.

[0029] The resonator is arranged at the bottom of the pump cavity, can be connected with an external signal generator through a circuit board, and has a GHz-level resonance frequency.

[0030] The pipe is a two-dimensional axisymmetric thin-walled pipe, the top of which is connected to the outlet. When the driven liquid in the pipe is working, the force on the part in contact with the inner wall of the pipe hinders its upward propagation, which is easy to cause backflow And reduce the back pressure, so the inner diameter below the pipe can be gradually reduced to reduce the loss of body force, suppress backflow, increase the back ...

Embodiment 2

[0035] In order to make the miniaturization and simplification of the present invention more prominent, the inventor made further improvements on the basis of Embodiment 1.

[0036] The resonator can be connected to the micro-miniature antenna through the circuit board, and the resonator can be driven to work by means of wireless power supply, which can realize the same function as the first embodiment, and can get rid of the shackles of wired connection, making it a portable portable micro-pump , the scope of application is wider and unrestricted.

[0037] The invention combines a GHz solid-package bulk acoustic wave resonator with a cavity with an intercepting pipeline to realize efficient pumping of liquid, and provides an acoustic fluid micropump based on microelectromechanical technology. The three-dimensional size of the pump body of the micropump is about 10 mm, which has the advantage of miniaturization; and there are no mechanical structures such as valves and membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com