Process method for improving abnormal conditions of tapping and roughing slag

A technology of abnormal conditions and process methods, applied in the field of iron and steel smelting, can solve the problems of poor purity of molten steel, etc., and achieve the effect of improving the quality of casting slabs, improving the ability, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

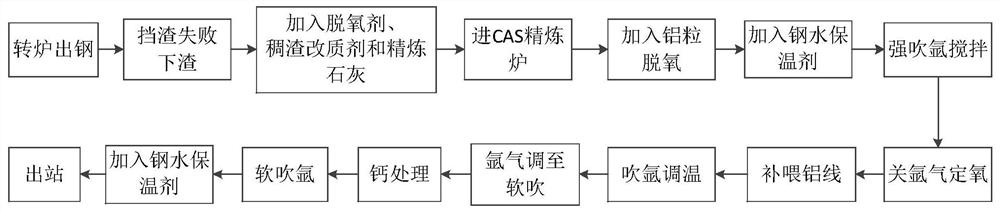

[0023] Please combine figure 1 As shown, for converter blowing-ladle argon blowing-continuous casting pouring process route, the present invention provides a process method to improve the abnormal situation of tapping slag, after adding aluminum particles and other deoxidizing materials after converter tapping, and then The molten steel heat preservation agent is added to promote the continuous melting of the top slag during the argon blowing process, reduce the viscosity of the top slag, improve the deoxidation and modification effect of the top slag, increase the stirring intensity and prolong the stirring time, and fully remove the molten steel inclusions.

[0024] Specifically include the following steps:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com