Lithium ion diaphragm containing lithium carbonate coating and preparation method of lithium ion diaphragm

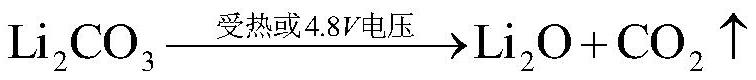

A technology of lithium carbonate and lithium ions, which is applied in the lithium ion diaphragm containing lithium carbonate coating and its preparation field, to achieve the effect of improving cycle life, large economic value and practical value, and increasing lithium ion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

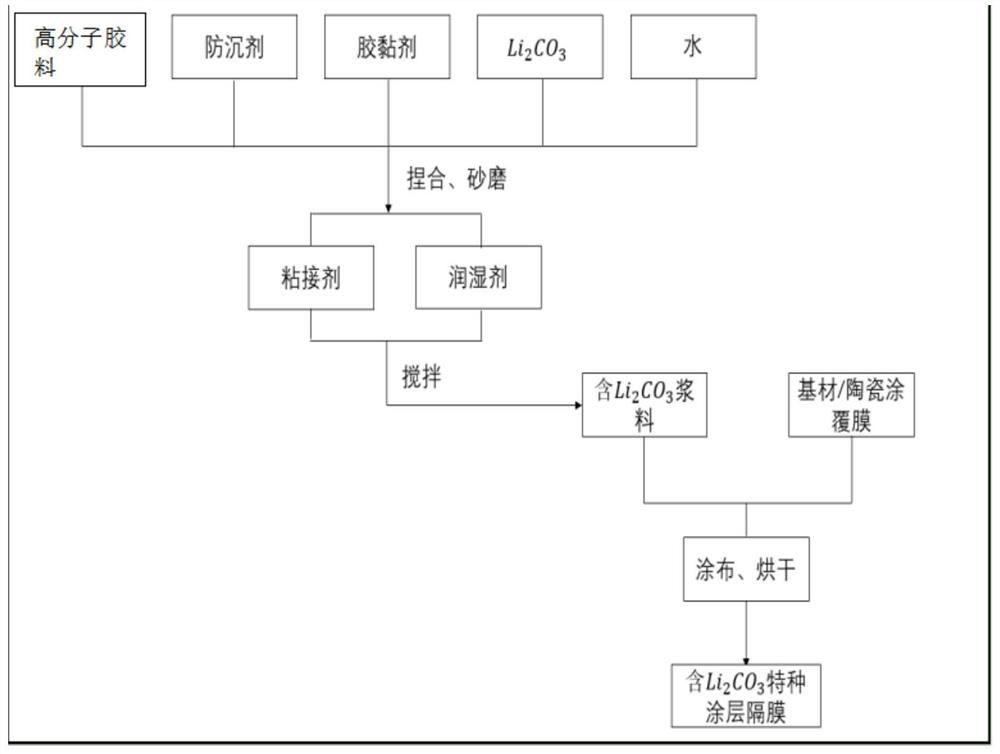

[0033] S1. Add the polymer rubber and lithium carbonate to the kneader for dry mixing and kneading. The stirring speed is controlled at 150r / min to obtain a mixed glue. Add anti-sedimentation agent, adhesive, and water to stir and moisten it, and suck it into the sand mill. Medium sand grinding for 1 hour, then continue to add binder and wetting agent to it and stir and mix for 10 minutes to obtain safety coating slurry.

[0034] S2. Coating the safety coating slurry on the surface of the base film;

[0035] S3. Dry the base film obtained in step S2. at 65° C. to obtain a lithium ion separator containing a lithium carbonate coating.

[0036] A kind of lithium ion membrane containing lithium carbonate coating mainly comprises: base film, the safety coating that is coated on the base film surface; Described safety coating mainly comprises mixed glue, auxiliary agent, water.

[0037] The addition amount of each raw material component in the safety coating is as follows: in perce...

Embodiment 2

[0051]S1. Add the polymer rubber and lithium carbonate to the kneader for dry mixing and kneading. The stirring speed is controlled at 150r / min to obtain a mixed glue. Add anti-sedimentation agent, adhesive, and water to stir and moisten it, and suck it into the sand mill. Medium sand grinding for 1 hour, then continue to add binder and wetting agent to it and stir and mix for 10 minutes to obtain safety coating slurry.

[0052] S2. Coating the safety coating slurry on the surface of the base film;

[0053] S3. Dry the base film obtained in step S2. at 65° C. to obtain a lithium ion separator containing a lithium carbonate coating.

[0054] A kind of lithium ion membrane containing lithium carbonate coating mainly comprises: base film, the safety coating that is coated on the base film surface; Described safety coating mainly comprises mixed glue, auxiliary agent, water.

[0055] The addition amount of each raw material component in the safety coating is as follows: in percen...

Embodiment 3

[0069] S1. Add the polymer rubber and lithium carbonate to the kneader for dry mixing and kneading. The stirring speed is controlled at 150r / min to obtain a mixed glue. Add anti-sedimentation agent, adhesive, and water to stir and moisten it, and suck it into the sand mill. Medium sand grinding for 1 hour, then continue to add binder and wetting agent to it and stir and mix for 10 minutes to obtain safety coating slurry.

[0070] S2. Coating the safety coating slurry on the surface of the base film;

[0071] S3. Dry the base film obtained in step S2. at 65° C. to obtain a lithium ion separator containing a lithium carbonate coating.

[0072] A kind of lithium ion membrane containing lithium carbonate coating mainly comprises: base film, the safety coating that is coated on the base film surface; Described safety coating mainly comprises mixed glue, auxiliary agent, water.

[0073] The addition amount of each raw material component in the safety coating is as follows: in perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com