Soft package lithium ion cell packaging method

A packaging method and cell packaging technology, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of wrinkling and leakage in the sealing area, small quantity, high cost, etc., so as to save the customization cycle and the packaging method is simple , Reduce the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

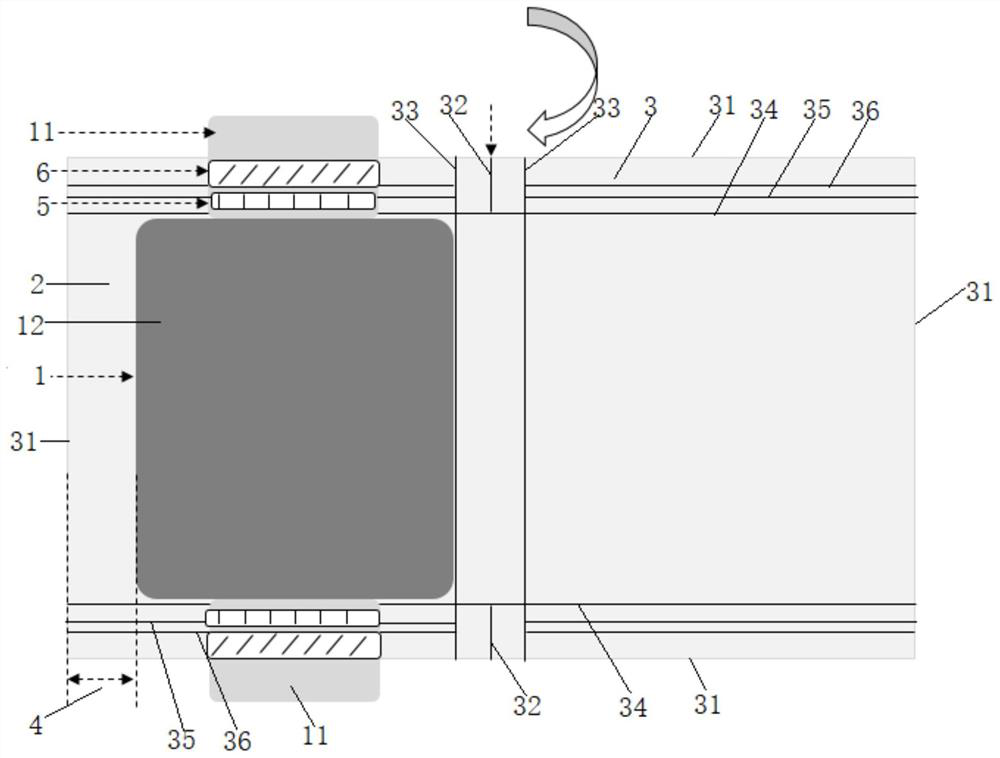

Image

Examples

Embodiment 1

[0042] A 10Ah soft-packed lithium-ion cell is used as the experimental sample cell, and 10 wound bare cells are used for the experiment at a time.

[0043] The specific steps of the experiment are as follows:

[0044] (1) Measure the size of the bare cell, that is, the length l 0 , width w 0 and thickness d 0 : Use a height gauge to measure the thickness of the wound bare cell at 11-12mm, and use an imager to measure the width of the bare cell at 61-62mm and the length of 120-122mm; (2) Cut the aluminum-plastic film: calculate the aluminum-plastic film Size (larger than the actual required size) and cut out the aluminum-plastic film that meets the size. Calculate the total length of the aluminum-plastic film according to the size of the bare cell L = 159 ~ 161mm and the total width W = 149 ~ 151mm, and then cut out the total length (3) Draw a line graph and copy it: select a standard plastic board or thin wood board as a drawing template, use a marker pen to draw edge line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com