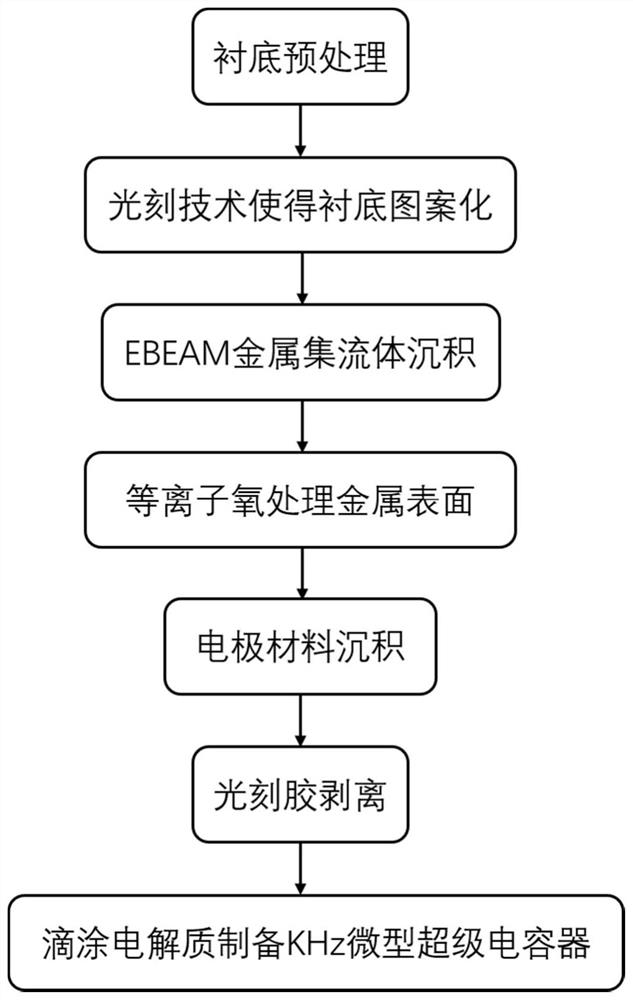

Preparation method of miniature supercapacitor capable of being used for kHZ alternating current linear filtering

A supercapacitor and linear filtering technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of low energy devices that can only be used for energy storage, to enhance adhesion and reduce charge Transmission impedance, the effect of increasing the characteristic frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Making SiO-based 2 Substrated PEDOT / PSS-based kHz planar micro-supercapacitors.

[0028] Step 1, for SiO 2 Substrate pretreatment.

[0029] Select SiO 2 The substrate, as the base of the whole device, was cleaned with deionized water, analytically pure acetone, and analytically pure ethanol in sequence, and then dried with nitrogen gas for later use.

[0030] Step 2, preparing a patterned substrate by photolithography.

[0031] 2a) The pretreated SiO 2 Put the sample on the glue-spinning machine, drip the positive glue AZ4620, rotate it at a speed of 4000r / s for 40s, then put it on the heating plate and dry it at 100°C for 120s to obtain a layer of AZ4620 photoresist with a thickness of 1.5μm , and then use the photolithography machine to make the structure photoresist-SiO 2 The sample was exposed for 4s to obtain a pattern with a microelectrode line width of 2 μm and a distance between electrodes of 5 μm;

[0032] 2b) The exposed photoresist SiO 2 Pu...

Embodiment 2

[0045] Embodiment 2: making a graphene-based kHz planar micro-supercapacitor based on a glass substrate.

[0046] Step 1, pretreating the glass substrate.

[0047] Select the glass substrate as the base of the overall device, and then use deionized water, analytically pure acetone, and analytically pure ethanol to ultrasonically clean several times, and then blow dry with nitrogen for later use;

[0048] Step 2, preparing a patterned substrate by photolithography.

[0049] 2.1) Put the pretreated glass sample on the glue machine, drip it with positive glue AZ6112, rotate it at a speed of 2000r / s for 40s, then put it on a heating plate and dry it at 100°C for 60s to obtain a glass with a thickness of 1.2μm. A layer of AZ6112 photoresist, and then use a photolithography machine to expose the sample with a photoresist-glass structure for 3s, and obtain a pattern with a microelectrode line width of 10 μm and a distance between electrodes of 20 μm.

[0050] 2.2) Put the exposed p...

Embodiment 3

[0063] Embodiment 3: Making a carbon nanotube CNT-based kHz planar micro-supercapacitor based on a PET substrate.

[0064] Step A, pretreating the PET substrate.

[0065] Select the PET substrate as the base of the overall device, and then use deionized water, analytically pure acetone, and analytically pure ethanol to ultrasonically clean each several times, then blow dry with nitrogen for later use;

[0066] In step B, a patterned substrate is prepared by photolithography.

[0067] In the first step, put the PET sample on the glue-spinning machine, drip it with negative glue AZ5214, rotate it at a speed of 4000r / s for 40s, then place it on a heating plate and dry it at 100°C for 120s to obtain a film with a thickness of 1.8μm. A layer of AZ5214 photoresist, and then use a photolithography machine to expose the structure of photoresist-PET for 5s, and obtain a pattern with a microelectrode line width of 50 μm and a distance between electrodes of 50 μm;

[0068] In the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com