Ground fracture stratum tunnel deformation joint anti-seepage device and construction method

A technology of anti-seepage devices and deformation joints, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as failure of anti-seepage structures, limited deformation of rubber waterstops, and pull damage of rubber waterstops. Effect of erosion, significant tensile deformation properties, good crack self-sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

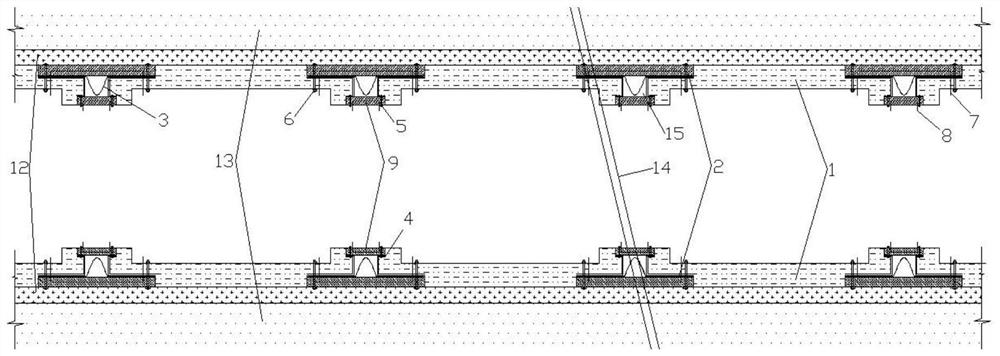

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] An anti-seepage device for deformation joints of tunnels in ground fissures, including an asphalt concrete cover plate 12 arranged on the outside of deformation joints 15, and the two ends of the asphalt concrete cover plate 12 are overlapped with the outside of the secondary lining 1 of the tunnel; A J-shaped steel plate 4 is pre-embedded in the secondary lining 1 on both sides of the lower part of the cover plate 1; a U-shaped waterstop 3 is provided between the bottom surface of the asphalt concrete cover plate 2 and the secondary lining 1 of the tunnel; the inner side of the deformation joint 15 An asphalt concrete cover plate 2 9 is provided, and both ends of the asphalt concrete cover plate 2 9 are overlapped with the inner side of the secondary lining 1 of the tunnel.

[0049] The primary lining 12 is located on the periphery of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com