Solar cell silicon wafer cleaning agent and solar cell silicon wafer cleaning method

A solar cell and silicon wafer cleaning agent technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of large silicon wafer thinning, poor uniformity, and low battery conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

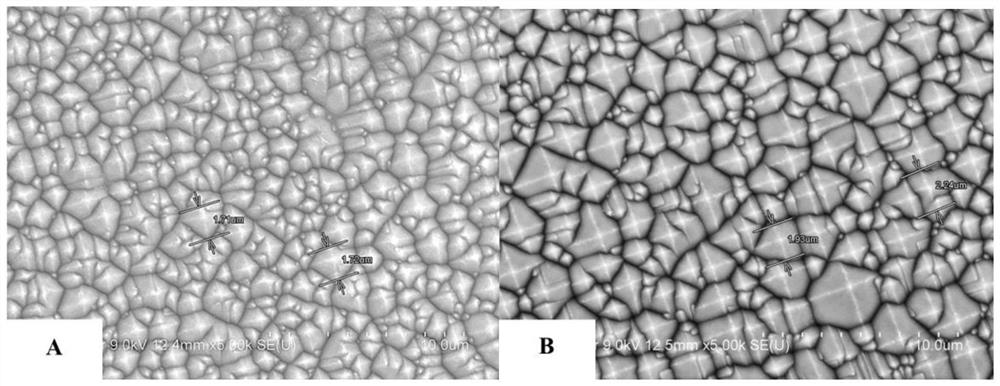

Image

Examples

Embodiment 1

[0039] 1. Prepare solar cell cleaning solution:

[0040] Take a 5L PP measuring cup, add 4.5L deionized water, then add 2g fatty alcohol polyoxyethylene ether, 3g sodium pyrophosphate, 5g sodium acetate, 0.5g protease, 1.5g lipase, 0.8g cellulase, 2.5g ethyl acetate Diaminetetraacetic acid and 5g of diethyltriaminepentaacetic acid were stirred evenly to prepare a cleaning agent; 250L of deionized water was added to the pre-cleaning tank, 2.5kg of sodium hydroxide was added to dissolve, and the temperature was raised to 45°C. Take 2.5L of the above-prepared cleaning agent and add it to the cleaning tank to get the cleaning solution.

[0041] 2. Solar cell wafer surface cleaning

[0042] The silicon wafers are added to the cleaning solution in batches of 400pcs (sheets) for 5 minutes, and then placed in a deionized water tank for rinsing. Each batch of wafers is cleaned.

[0043] 3. Monocrystalline silicon texturing

[0044] Add 350L of deionized water to the texturing tank,...

Embodiment 2

[0046] 1. Prepare solar cell cleaning solution:

[0047] Take a 5LPP measuring cup, add 4.5L deionized water, then add 1.0g fatty alcohol polyoxyethylene ether, 1.5g polyoxypropylene polyoxyethylene block copolymer, 10g sodium acetate, 1.0g lipase, 0.8g cellulase, 1.2g of amylase and 20g of diethyltriaminepentaacetic acid, stir evenly, and prepare a cleaning agent; add 250L of deionized water to the pre-cleaning tank, add 2.5kg of sodium hydroxide to dissolve, and heat up to 50°C. Add 2.5L of the above-prepared cleaning agent into the cleaning tank to obtain a cleaning solution.

[0048] 2. Solar cell wafer surface cleaning

[0049] The silicon wafers were added to the cleaning solution in batches of 400pcs for 5 minutes, then put into deionized water for rinsing, and then the cleaning solution was replenished. After each batch of cleaning, 30ml of cleaning agent was added. Wafer cleaning.

[0050] 3. Monocrystalline silicon texturing

[0051] Add 350L of deionized water t...

Embodiment 3

[0053] 1. Prepare solar cell cleaning solution:

[0054] Take a 5L PP measuring cup, add 4.5L deionized water, then add 1.4g fatty alcohol polyoxyethylene ether, 30g sodium pyrophosphate, 50g sodium acetate, 0.3g protease, 0.5g lipase, 0.3g cellulase, 15g ethyl acetate Diaminetetraacetic acid and 15g of diethyltriaminepentaacetic acid were stirred evenly to prepare a cleaning agent; 250L of deionized water was added to the pre-cleaning tank, 2.5kg of sodium hydroxide was added to dissolve, and the temperature was raised to 45°C. Take 2.5L of the above-prepared cleaning agent and add it to the cleaning tank to get the cleaning solution.

[0055] 2. Solar cell wafer surface cleaning

[0056] The silicon wafers are added to the cleaning solution in batches of 400pcs (sheets) for 5 minutes, and then placed in a deionized water tank for rinsing. Each batch of wafers is cleaned.

[0057] 3. Monocrystalline silicon texturing

[0058] Add 350L of deionized water to the texturing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com