Oligomer suitable for photocuring ink-jet ink and preparation method thereof

An inkjet ink and oligomer technology, which is applied in the field of photocurable inkjet ink oligomers and its preparation, can solve the problems of ink printing instability, poor fluidity, and insufficient cohesion, so as to ensure printing fluency , Excellent dilutability, low curing shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

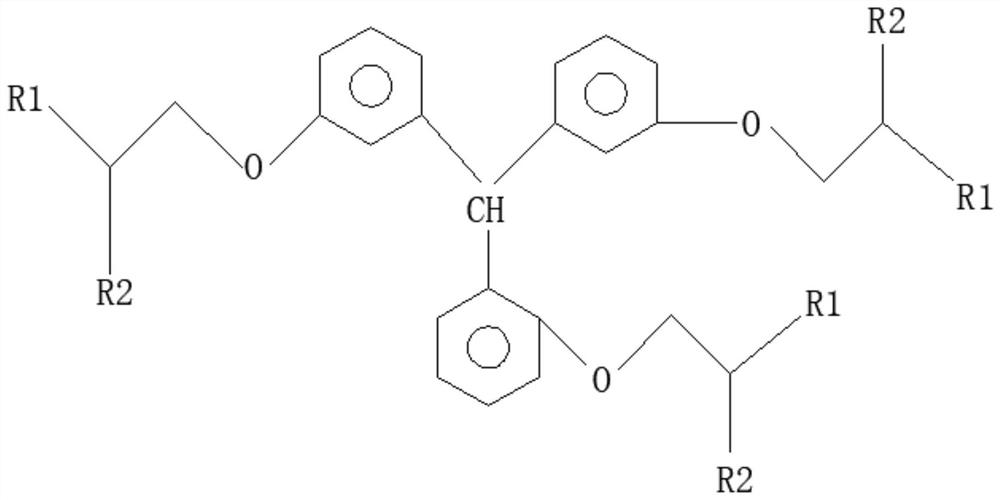

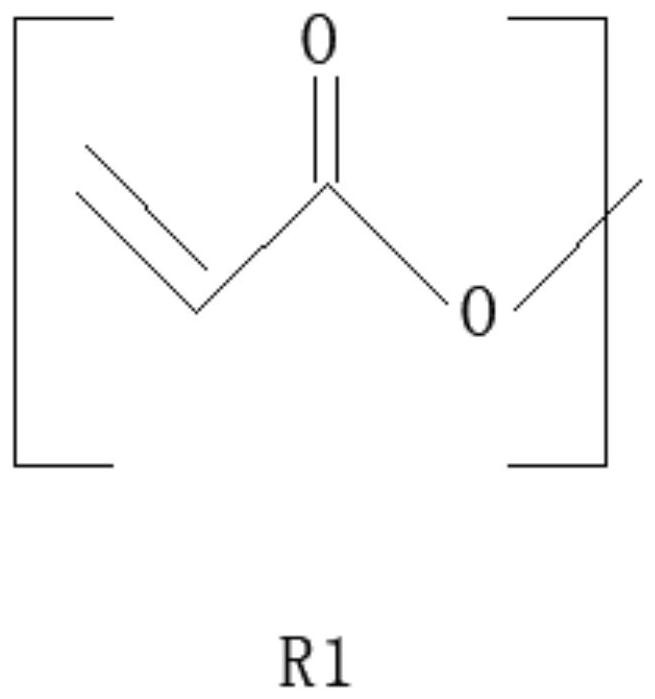

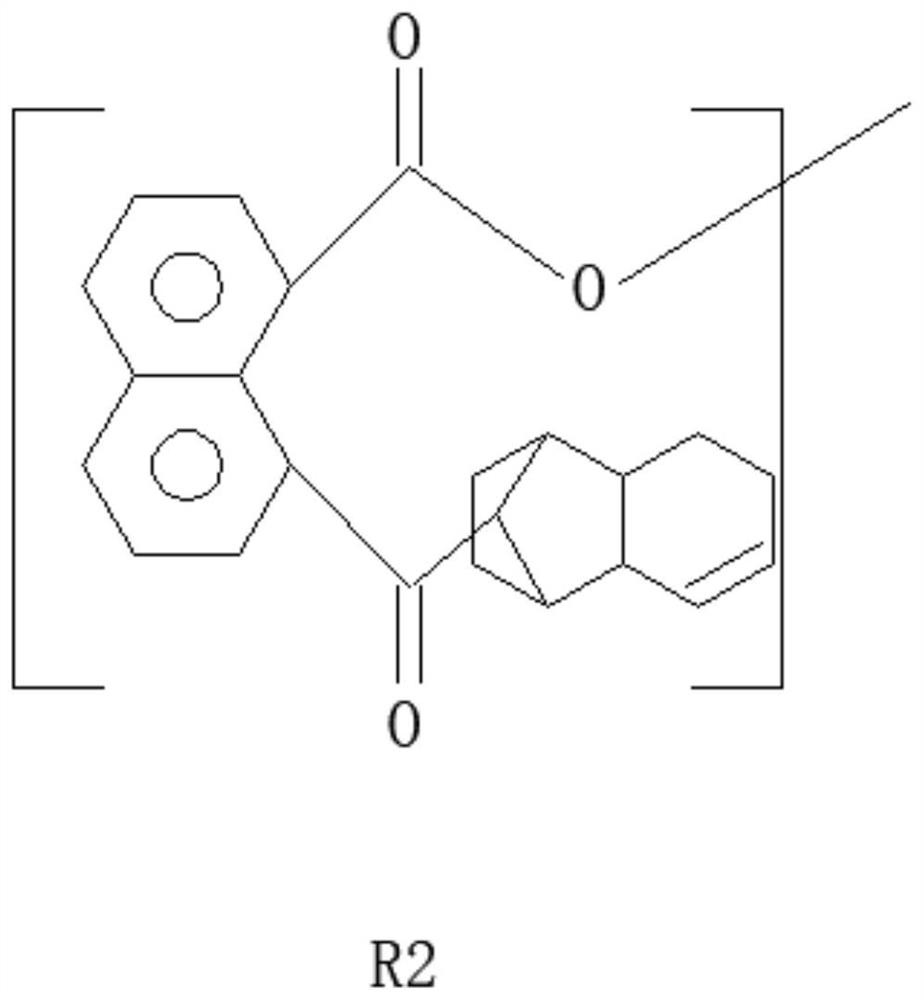

[0038] refer to Figure 1-3 , an oligomer suitable for photocurable inkjet inks, prepared from the following raw materials: trisphenolyl methane triglycidyl ether, acrylic acid, 1,8-naphthalene dicarboxylic anhydride, dicyclopentadiene, and synthetic auxiliary materials .

[0039] Synthetic auxiliary raw materials specifically include the following materials: hydroquinone, triphenylphosphine, trifluoromethanesulfonic acid, p-hydroxyanisole and ACMO monomer.

[0040] A method for preparing an oligomer suitable for light-curing inkjet inks, comprising the following steps:

[0041] S1: First add 460g of trisphenolyl methane triglycidyl ether, 0.6g of hydroquinone, and 3g of catalyst triphenylphosphine into a two-necked flask, then install a stirrer and a heating device, stir and heat to 85°C, and wait for the resin After liquefaction, slowly pour in 216g of acrylic acid while stirring, heat to 105°C and keep the temperature constant, and pass through protective gas for protecti...

Embodiment 2

[0048] An oligomer suitable for photocurable inkjet inks, mainly prepared from the following raw materials: trisphenolyl methane triglycidyl ether, acrylic acid, 1,8-naphthalene dicarboxylic anhydride, dicyclopentadiene and synthetic auxiliary materials Specifically, the following materials are included: hydroquinone, triphenylphosphine, trifluoromethanesulfonic acid, p-hydroxyanisole and ACMO monomer.

[0049] Synthetic auxiliary raw materials specifically include the following materials: hydroquinone, triphenylphosphine, trifluoromethanesulfonic acid, p-hydroxyanisole and ACMO monomer.

[0050] A method for preparing an oligomer suitable for light-curing inkjet inks, comprising the following steps:

[0051] S1: First add 460g of trisphenolyl methane triglycidyl ether, 0.6g of hydroquinone, and 3g of catalyst triphenylphosphine into a two-necked flask, then install a stirrer and a heating device, stir and heat to 85°C, and wait for the resin After liquefaction, pour 72g of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com