Plug flow reactor for petrochemical wastewater treatment

A petrochemical waste water and plug-flow technology, which is applied in natural water treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of poor environmental adaptability, low purification efficiency, and poor purification effect, and achieve stable, Guarantee the purification effect and improve the effect of purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

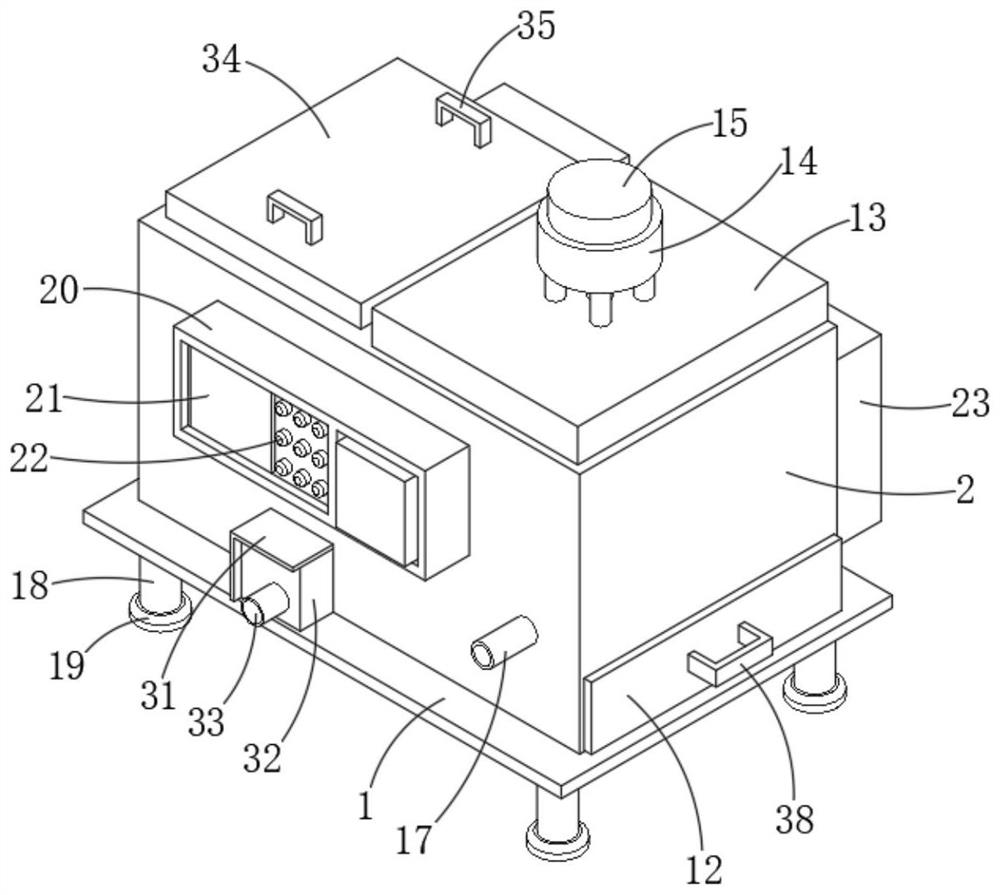

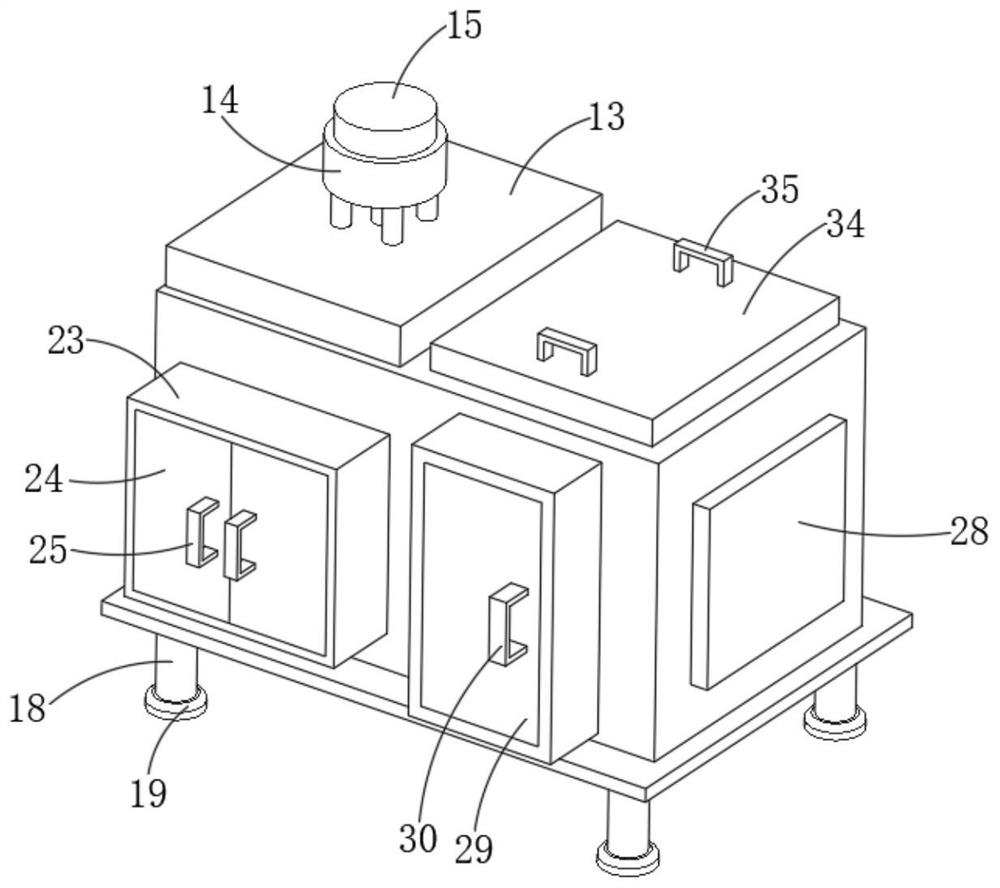

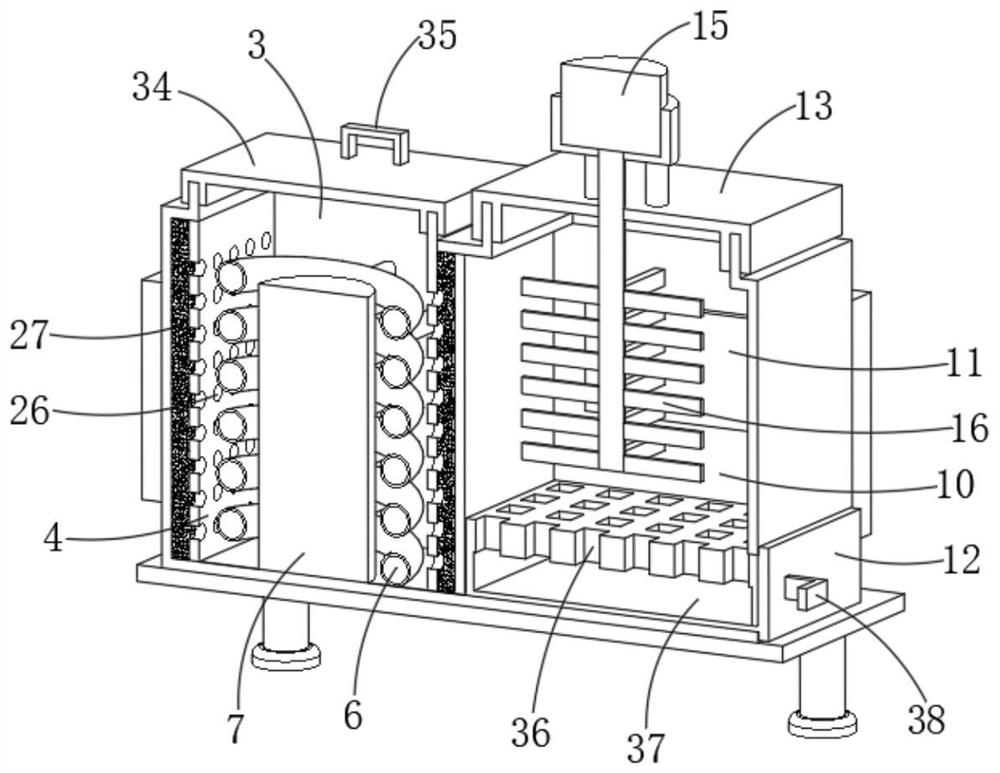

[0029] see Figure 1-6 , the present invention provides the following technical solutions: a plug-flow reactor for petrochemical wastewater treatment, comprising a bottom plate 1, a plug-flow pipeline 6 and a sedimentation tank 12, the upper surface of the bottom plate 1 is fixedly connected with a box body 2, and the inner bottom of the box body 2 One side of the wall is provided with a reaction box 3, the inner wall of the reaction box 3 is fixedly connected with an inner shell 4, the two sides of the inner wall of the inner shell 4 are fixedly connected with a support rod 5, and one end of the support rod 5 is fixedly connected with a push flow pipe 6, The shell 4 is fixedly connected with an electric heating column 7 near the inner bottom wall of the pushing flow pipeline 6, and the outer surface of the box body 2 near the reaction box 3 is fixedly connected with a feeding box 8, and the outer surface of the feeding box 8 is penetrated with a material pipe 9 and extends to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com