Manufacturing process of ethylene propylene diene monomer waterproof coiled material

A technology of EPDM rubber and waterproof membrane, applied in the field of waterproof membrane manufacturing, can solve the problems of affecting the processing efficiency of equipment, increasing the processing cost of equipment, loss of raw material temperature, etc., to prevent heat leakage, quick disassembly and installation , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

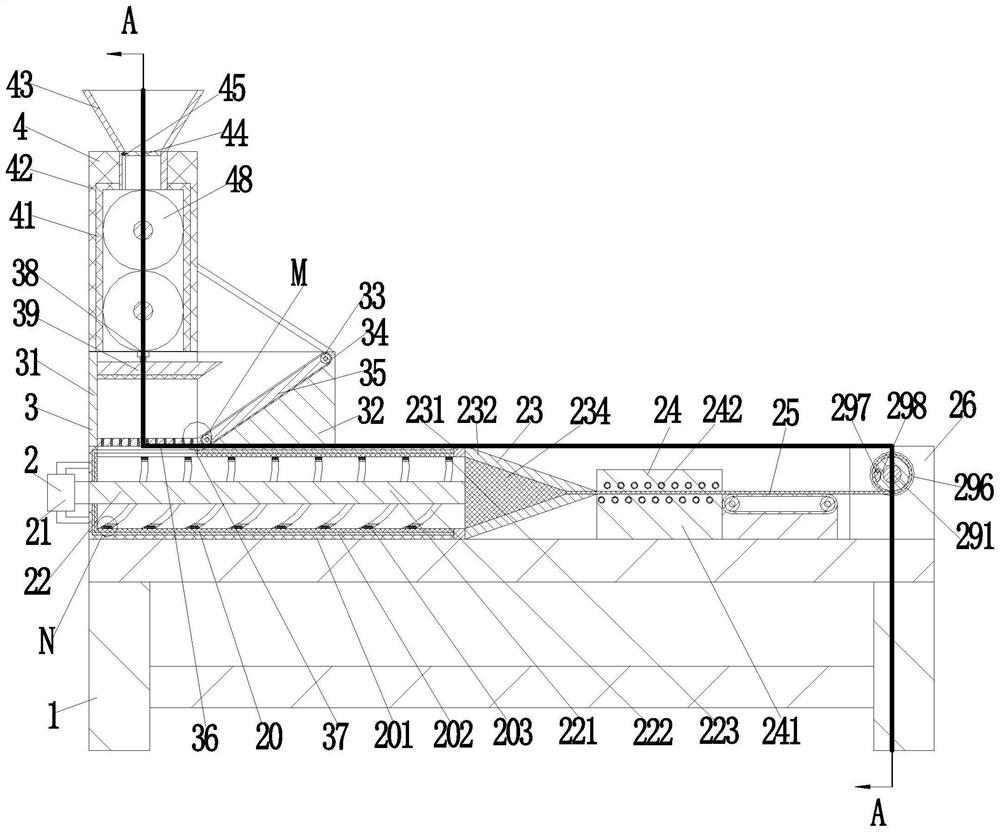

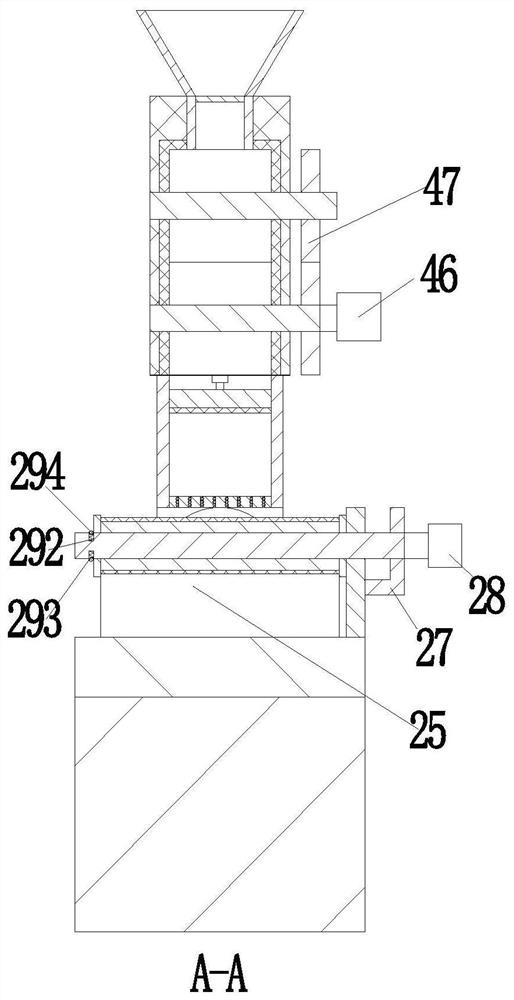

[0035] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

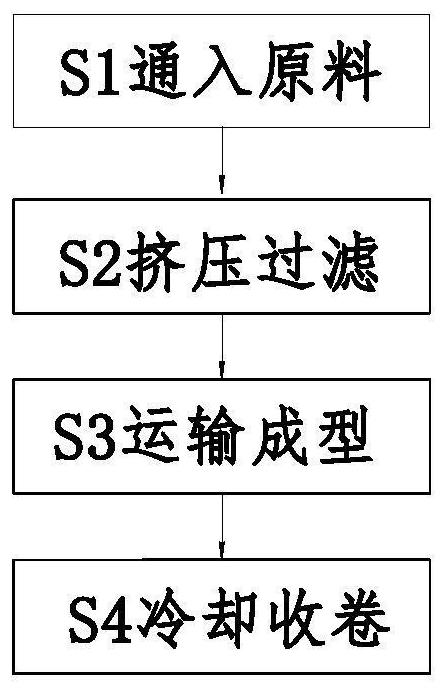

[0036] A kind of EPDM waterproof membrane manufacturing process, it uses a kind of EPDM waterproof membrane manufacturing equipment, this EPDM waterproof membrane manufacturing equipment includes workbench 1, extruding device 2, Pretreatment device 3 and heating device 4, the concrete method when adopting above-mentioned EPDM waterproof membrane manufacturing equipment to manufacture EPDM waterproof membrane is as follows:

[0037] S1, feeding raw materials: passing the raw materials into the heating cylinder 41 through the feeding funnel 43 for heating and stirring;

[0038] S2. Squeeze and filter: transport the heated and stirred raw materials to the left side of the guide tank 32 through the guide tank 32. At this time, the electric cylinder 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com