Machining method for small-batch production of O-shaped sealing ring fixing pieces

A processing method and a technology of fixing pieces, which are applied in the field of special-shaped gasket processing and small size, can solve problems such as difficult clamping, difficulty in ensuring dimensional accuracy, and difficulty in clamping small-sized workpieces. pinch difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0025] A processing method for small-batch production of an "O" type sealing ring fixed piece, comprising the steps of:

[0026] a. Material selection, choose the material with the size of 100×60×40 corresponding to the grade;

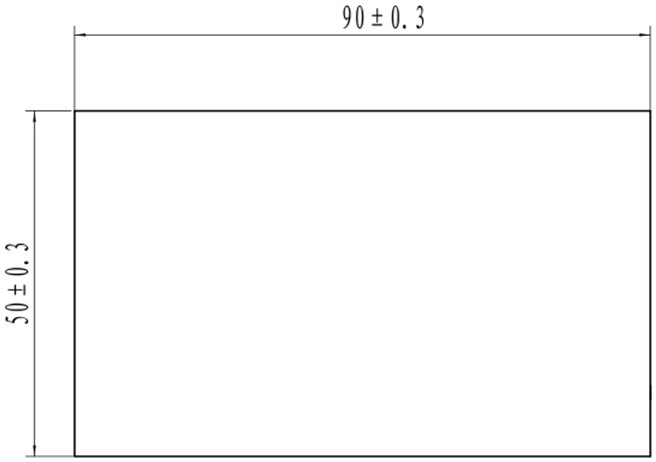

[0027] b. If figure 1 and figure 2 As shown, the selected material is milled on a milling machine to a size of 90±0.3×50±0.3×30±0.3 for use;

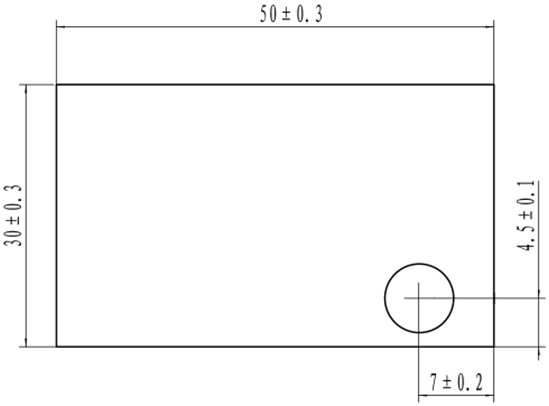

[0028] c. If image 3 and Figure 4 As shown, the milled material is drilled on the vertical machining center with a hole of φ7±0.2×90, and the guaranteed size is 7±0.2, 4.5±0.1;

[0029] d. If Figure 5 As shown, according to the size of the workpiece material to be processed, the material with the hole drilled in step c is subjected to slow wire cutting on the electric discharge CNC wire cutting machine for standby;

[0030] e. If Figure 6 and Figure 7 As shown, according to the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com