A welding method for realizing T-joint between ultra-thin plate and small-diameter bar

A welding method and small-diameter technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of large resistance difference, difficulty in repeatedly obtaining joints, offset, etc., and achieve the effect of avoiding overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

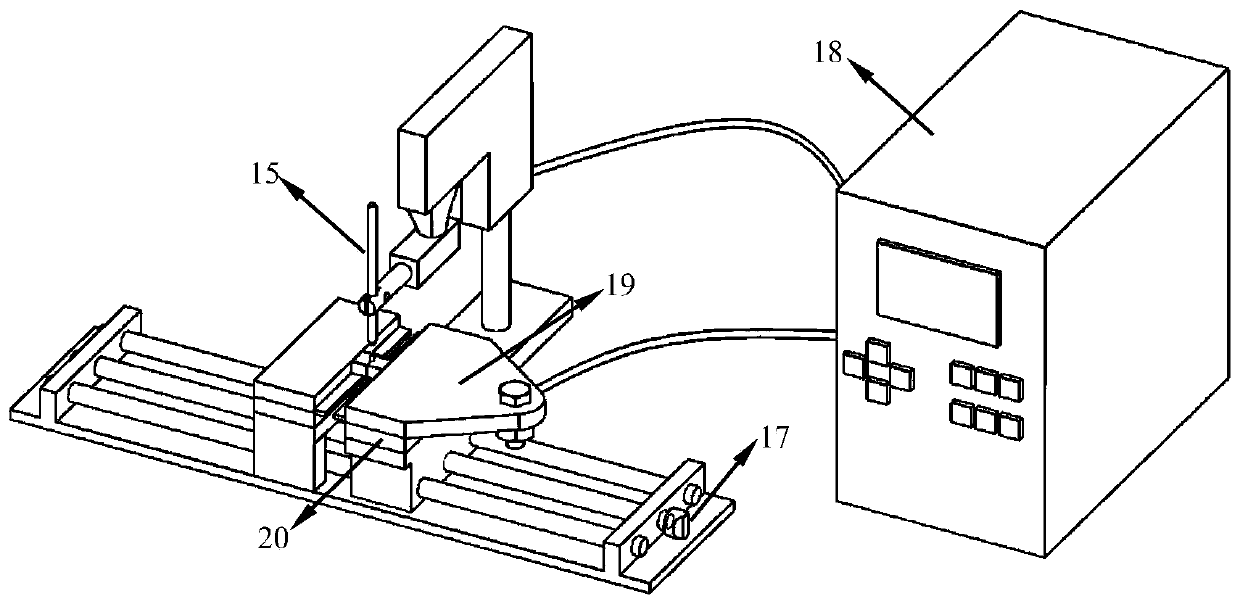

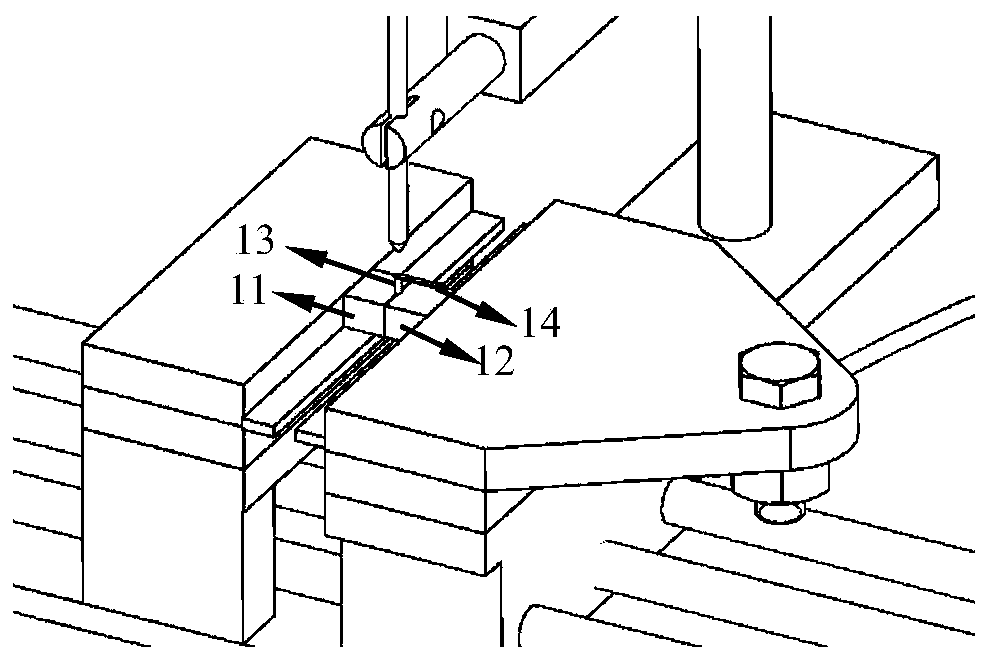

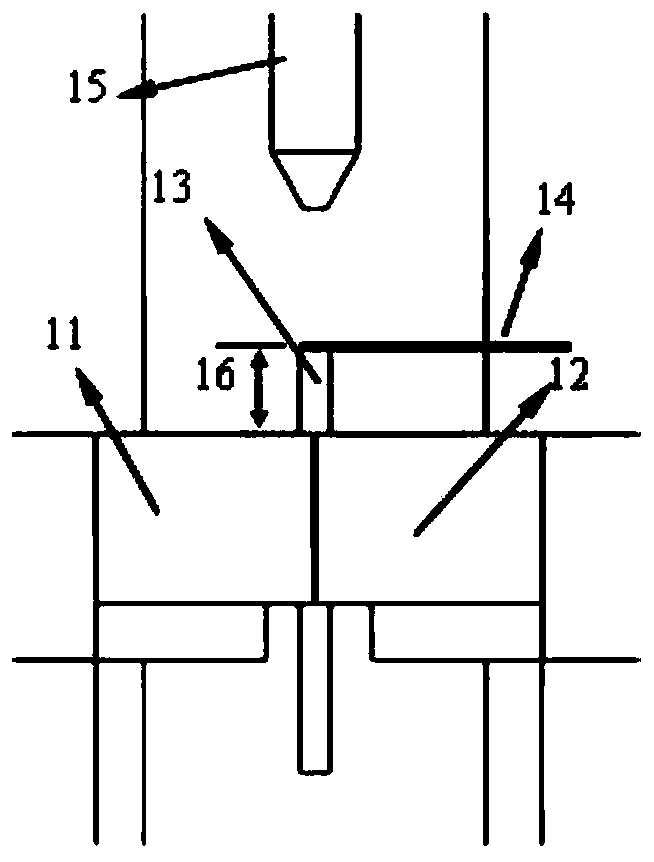

[0028] The invention relates to a welding method for realizing a T-shaped connection between an ultra-thin plate and a small-diameter bar, figure 1 It is a welding device of the present invention and an assembly schematic diagram, figure 2 for figure 1 Zoom in on part of the schematic, image 3 Schematic diagram for welding. The material of the small-diameter bar is pure molybdenum with a diameter of 1.2mm, and the material of the ultra-thin metal plate is 304 stainless steel with a thickness of 0.3mm. First, use 800-grit sandpaper to polish the end surface of the molybdenum rod to be welded evenly, and polish the stainless steel ultra-thin plate to be welded to remove the surface oxide layer. The molybdenum rods and stainless steel ultra-thin plates were cleaned in an ultrasonic cleaning pool with acetone, and dried after cleaning. Loosen the tightening knob (17), place the small-diameter rod (13) between the movable conductive block one (11) and the movable conductive b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com