Fly ash high-temperature melting treatment method and system, control device and storage medium

A technology of high-temperature melting and processing method, which is applied in the field of resource utilization of solid waste, which can solve the problems of long maintenance time, high requirements for melting temperature, and high energy consumption, and achieve the effects of improving efficiency, reducing energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

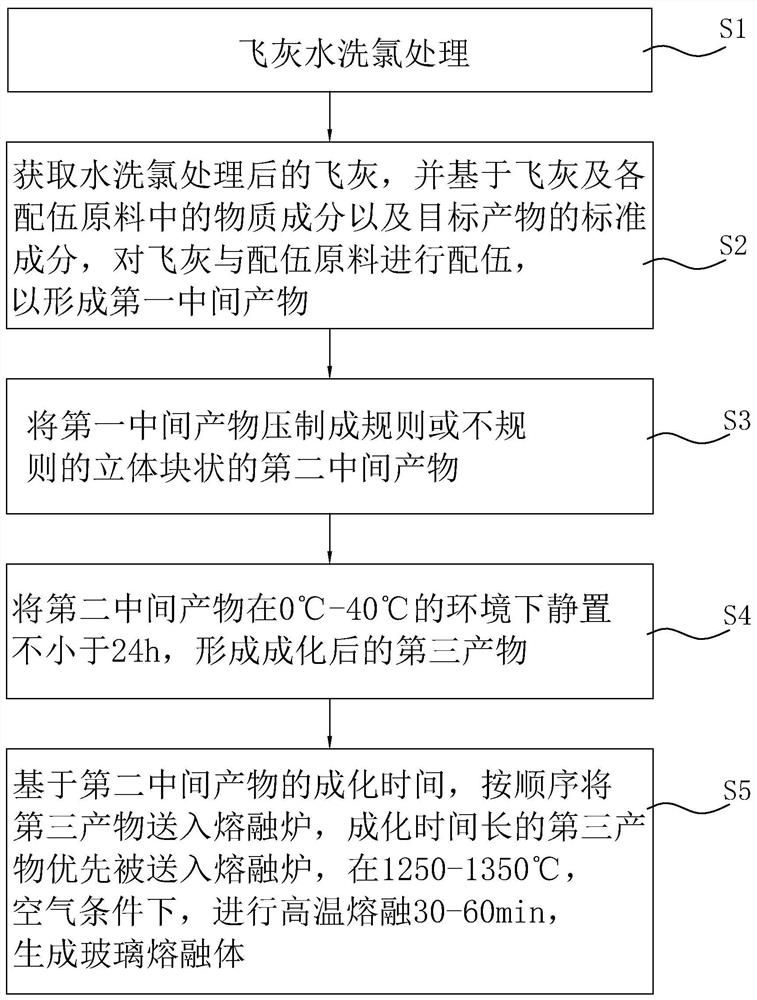

[0086] The application will be described in further detail below in conjunction with the accompanying drawings.

[0087] The embodiment of the present application provides a high-temperature melting treatment method for fly ash.

[0088] Such as figure 1 shown, including:

[0089] S1: Fly ash water elution chlorine treatment, specifically including:

[0090] S11: Analyze the chlorine content in the fly ash through multi-point and multi-frequency sampling analysis, that is, establish a multi-tank simultaneous ash discharge operation mechanism, and analyze the chlorine content of the fly ash to be processed every 4 hours;

[0091] S12: According to the analysis result in S11, determine the flow rate of washing water, and the water-cement ratio is controlled at 2-4:1;

[0092] S13: The fly ash is washed by a multi-stage countercurrent washing process, and the ash water washed in the next stage is separated from solid and liquid by dehydration and pressure filtration. Fresh wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com