Z-type zinc sulfide/polyimide composite material and application thereof in degradation of tetracycline antibiotic wastewater

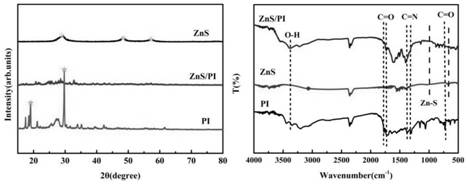

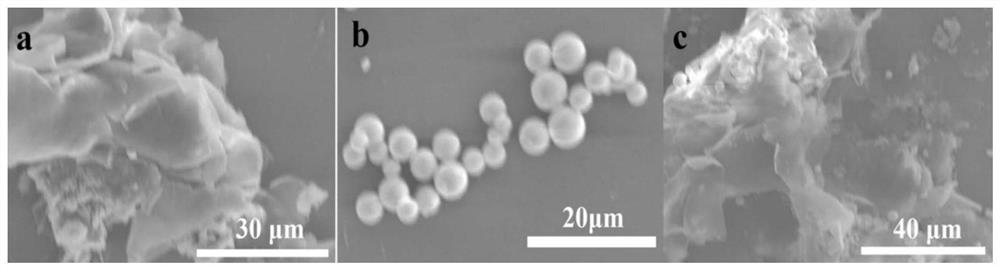

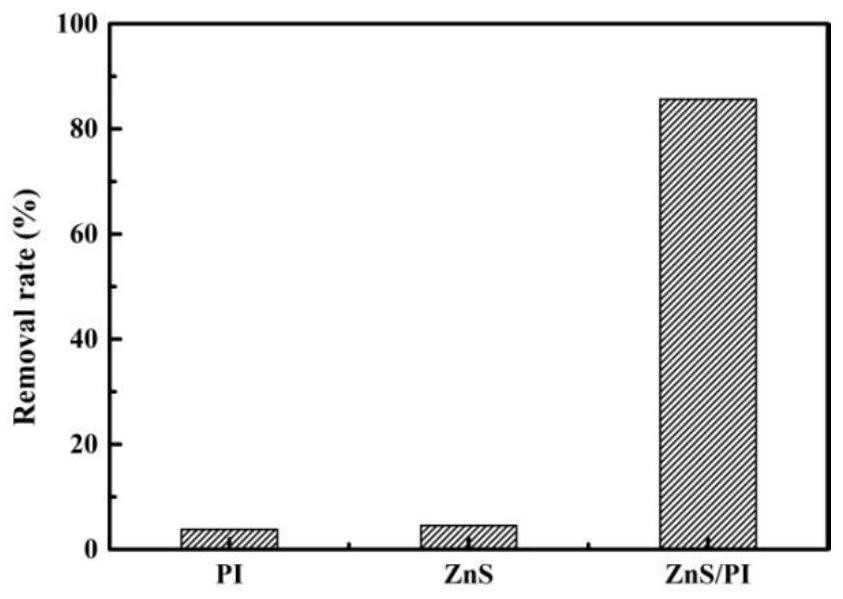

A composite material and mixed material technology, which is applied in the fields of special compound water treatment, organic compound/hydride/coordination complex catalyst, chemical/physical process, etc. problems such as low rate, to achieve the effects of excellent thermal stability and chemical stability, simple preparation process and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a composite degradable material, comprising the steps of:

[0030] 1) Take 2.520g of melamine and 4.360g of pyromellitic dianhydride as mixed raw materials, mix them uniformly in a crucible and grind them thoroughly to obtain mixed powder.

[0031] 2) Put the mixed powder obtained in step 1) into a muffle furnace for calcination, the temperature is set at 325°C, and the calcination time is 4 hours, so that the raw materials can fully react to obtain a calcined material.

[0032]3) The calcined material obtained in step 2) is completely ground into powder, washed with deionized water at 50°C to remove unreacted monomers, and dried in an oven at 60°C to remove excess water to obtain solid powder.

[0033] 4) Disperse the solid powder obtained in step 3) in 25 mL of deionized water, sonicate in a water bath for 4 hours, centrifuge, and then dry in an oven at 60°C to obtain the prepared PI material.

[0034] 5) Disperse 1.365g of zinc acetate dihydr...

Embodiment 2

[0040] A method for preparing a composite material, comprising the steps of:

[0041] 1) Take 2.520g of melamine and 4.360g of pyromellitic dianhydride as mixed raw materials, mix them uniformly in a crucible and grind them thoroughly to obtain mixed powder.

[0042] 2) Put the mixed powder obtained in step 1) into a muffle furnace for calcination, the temperature is set at 325°C, and the calcination time is 4 hours, so that the raw materials can fully react to obtain a calcined material.

[0043] 3) The calcined material obtained in step 2) is completely ground into powder, washed with deionized water at 50°C to remove unreacted monomers, and dried in an oven at 60°C to remove excess water to obtain solid powder.

[0044] 4) Disperse the solid powder obtained in step 3) in 25 mL of deionized water, sonicate in a water bath for 4 hours, centrifuge, and dry in an oven at 60°C to obtain the prepared PI material.

[0045] 5) Disperse 1.117g of zinc acetate dihydrate and 0.393g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com