Preparation method of nanocellulose reinforced collagen casing

A nanocellulose and collagen technology, which is applied in the field of preparation of nanocellulose reinforced collagen casings, can solve the problems of inability to take into account production cost, simple processing and required performance, poor water resistance and gas barrier properties of casings, and the like. The effect of broadening the application, improving the mechanical properties and reducing the loss of leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

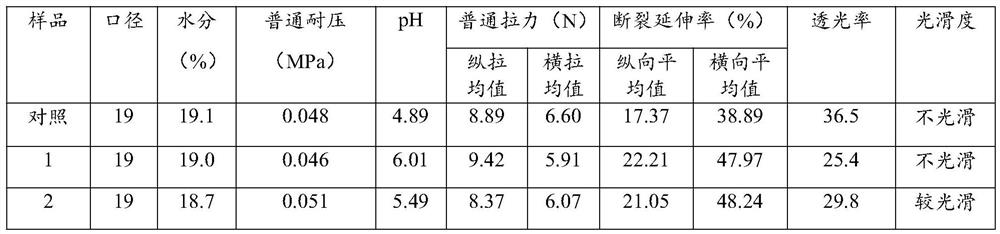

Embodiment 1

[0050] Preparation method of nano-cellulose reinforced collagen sausage casing:

[0051] (1) cleaning and splitting the inner layer of cowhide to obtain a second layer of skin;

[0052] (2) Soak the split skin with soda lime water, and adjust the pH to 12, and the treatment time is 2 hours. Cut 5kg of split leather into small pieces of 10cm×10cm, soak in distilled water every 2 hours until the pH is neutral, then take it out and drain to obtain neutral cowhide;

[0053] (3) Submerge the neutral cowhide piece in 0.03mol / L hydrochloric acid, and fully acid-swell it at 20°C for 24 hours; wherein, cowhide:hydrochloric acid=1:3 (W / V);

[0054] (4) Gently scrape the collagen fibers of the swollen cowhide piece with tweezers, configure it into a 0.5wt% collagen fiber suspension with distilled water, and then use hydrochloric acid to adjust the pH of the suspension to 2;

[0055] (5) Simultaneously, add the purified cotton linters to NaOH solution, basify at room temperature for 2 h...

Embodiment 2

[0060] Take 50kg of cow split hide, wash it in a pool, divide it into 10*10cm pieces, soak it with 90kg of soda lime for 1 day, and add 50kg of water after cleaning. Treat at room temperature for 6h to neutral. After cleaning, put it into hydrochloric acid with a concentration of 0.03mmol / L and carry out acidification treatment for 24 hours, and then chop it with a chopping machine.

[0061] Simultaneously, add the purified cotton linters to NaOH solution, alkalinize at room temperature for 2 hours, then add absolute ethanol and 35.5% sodium monochloroacetate, mix well, place in a water bath at 70°C for 5 hours, and wash with distilled water after the reaction. Neutral, then dispersed to a concentration of 1%, and then subjected to high-pressure homogenization, set the pressure of high-pressure homogenization to 1500 bar, and the number of homogenization times to 4 times.

[0062] Then the 1wt% CNF suspension was stirred in a magnetic stirrer, and added to the 1wt% collagen s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com