Electrolyte of aluminum electrolytic capacitor, aluminum electrolytic capacitor and electronic device

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of electrochemistry, can solve problems such as valve opening, bulging, and failure of products, and achieve the effects of prolonging life, reducing internal air pressure, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

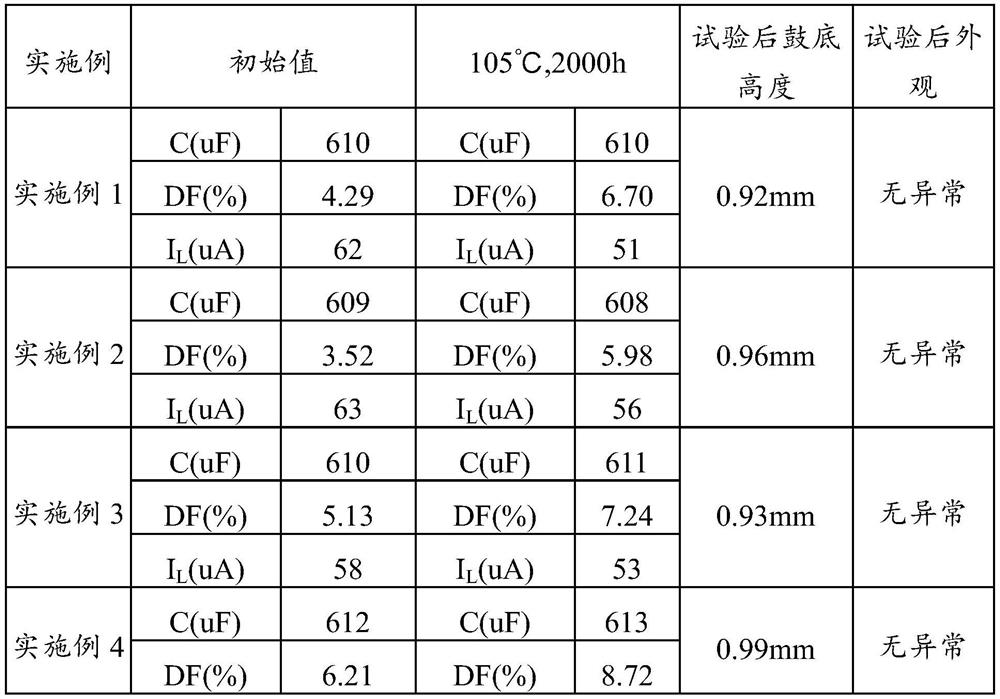

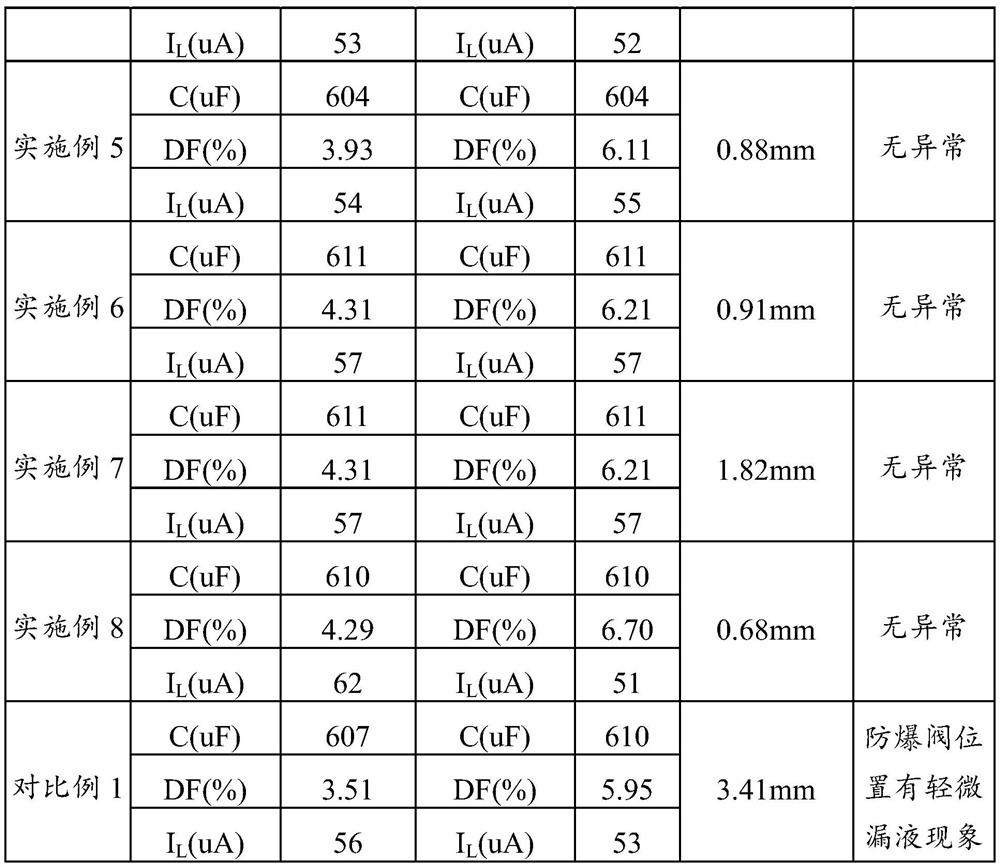

Examples

Embodiment 1

[0051] Formula: alcohol solvent (ethylene glycol) 55.9%, auxiliary solvent (diethylene glycol 18%, mannitol 2%) 20%, solute (boric acid 1%, ammonium hydrogen azelate 1%, ammonium benzoate 1%, 2,7-dibutyl ammonium suberate 3%, alkyl ammonium sebacate 8%, 11-vinyl-8-octadecenedioic acid 4.4%, butyl phosphate 0.1%) 18.5%, flash fire Voltage booster (polyvinyl alcohol 0.5%, SiO 2 Dispersion liquid 2.5%) 3%, corrosion inhibitor (ammonium hypophosphite) 0.1% and new hydrogen remover (2-methyl-2-(4-nitrobenzene)-1,3-dioxane ) 2.5%.

[0052] Preparation method: Add ethylene glycol into the reaction bottle to start heating, and under stirring conditions, add polyvinyl alcohol when heated to 145°C, and keep warm for 30 minutes; when the temperature drops to 140°C, add diethylene glycol, keep warm for 5 minutes; wait for the temperature to drop Add mannitol and boric acid at 130°C and keep warm for 20 minutes; then add 11-vinyl-8-octadecenedioic acid, butyl phosphate, ammonium hydrogen...

Embodiment 2

[0054] Formula: alcohol solvent (ethylene glycol) 63.9%, auxiliary solvent (diethylene glycol 10%, mannitol 2%) 12%, solute (boric acid 1%, 11-vinyl-8-octadecenedioic acid 4.4% , butyl phosphate 0.1%, ammonium dodecanoate 1%, ammonium benzoate 1%, 2,7-dibutyl ammonium suberate 3%, alkyl ammonium sebacate 8%) 18.5%, flash fire Voltage booster (polyvinyl alcohol 0.5%, SiO 2 Dispersion liquid 2.5%) 3%, corrosion inhibitor (ammonium hypophosphite) 0.1% and new hydrogen remover (2-methyl-2-(4-nitrobenzene)-1,3-dioxane ) 2.5%.

[0055]Preparation method: Add ethylene glycol into the reaction bottle to start heating, and under stirring conditions, add polyvinyl alcohol when heated to 145°C, and keep warm for 30 minutes; when the temperature drops to 140°C, add diethylene glycol, keep warm for 5 minutes; wait for the temperature to drop Add mannitol and boric acid at 130°C and keep warm for 20 minutes; then add 11-vinyl-8-octadecenedioic acid, butyl phosphate, ammonium dodecanoate a...

Embodiment 3

[0057] Formula: alcohol solvent (ethylene glycol) 62.8%, auxiliary solvent (diethylene glycol 10%, mannitol 2%) 12%, solute (ammonium sebacate 3%, ammonium benzoate 1%, alkyl sebacic acid Ammonium 10%, 11-vinyl-8-octadecenedioic acid 4.9%, butyl phosphate 0.1%, ammonium pentaborate 2%) 21%, flash voltage booster (polyethylene glycol 1%, polyethylene Alcohol 0.5%) 1.5%, corrosion inhibitor (ammonium hypophosphite) 0.2% and new hydrogen remover (2-methyl-2-(4-nitrobenzene)-1,3-dioxane) 2.5%.

[0058] Preparation method: Add ethylene glycol, diethylene glycol and polyethylene glycol respectively into the reaction bottle, and start heating under stirring conditions, and add ammonium sebacate, ammonium benzoate and alkyl ammonium sebacate when heating to 80°C , 11-vinyl-8-octadecenedioic acid, and butyl phosphate are fully dissolved, continue to add polyvinyl alcohol and raise the temperature to 140°C, and keep warm for 30 minutes; then add ammonium pentaborate, ammonium hypophosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com