Oil supplementing system of rotary motor and excavator

A technology of rotary motor and oil replenishment valve, which is applied in the direction of earth mover/shovel, construction, etc., and can solve the problems of increased oil return back pressure, reduced work efficiency, and increased fuel consumption of excavators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

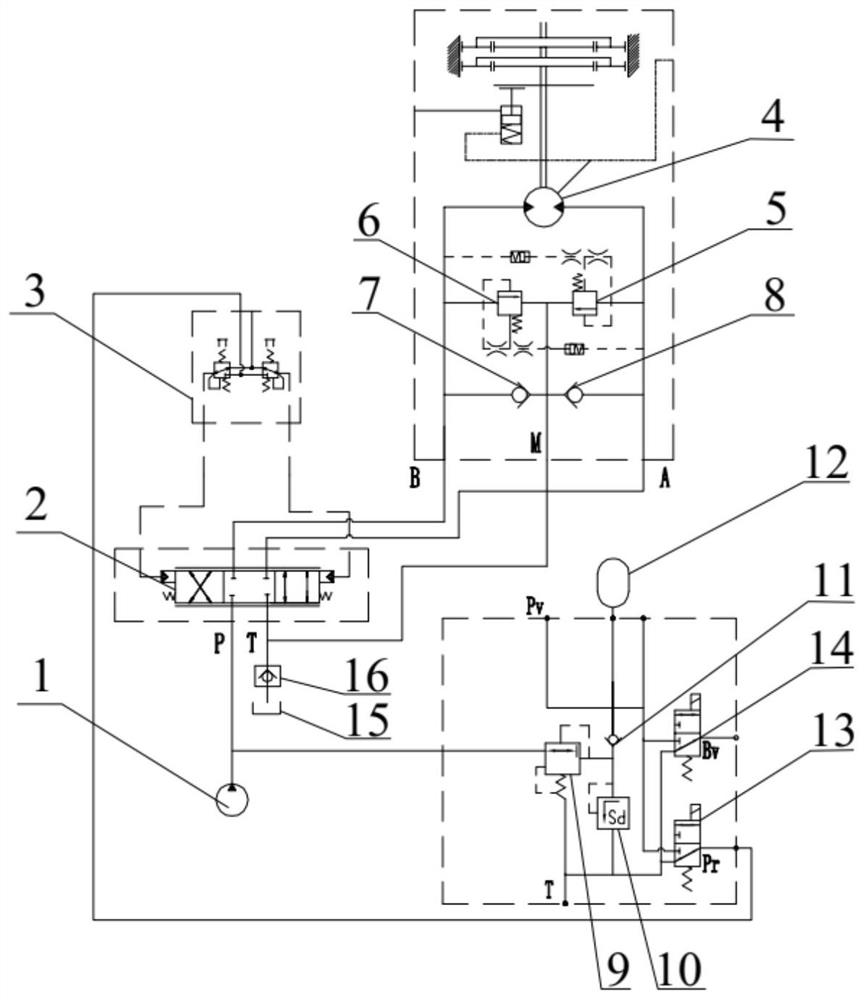

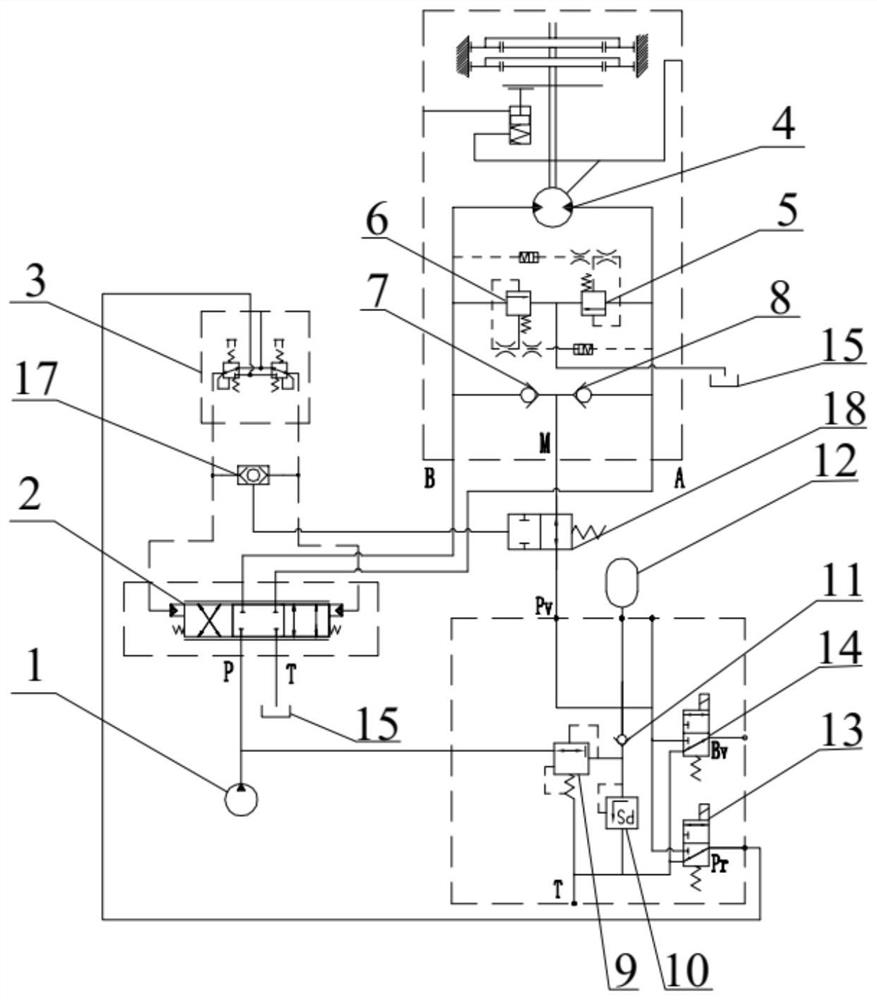

Embodiment 1

[0033] Such as figure 2 As shown, this embodiment provides an oil replenishment system for a rotary motor, including a main pump 1, a hydraulic control reversing valve 2, a pilot oil source valve, a pilot handle 3, a rotary motor 4, a shuttle valve 17 and an oil replenishment valve 18 , the oil outlet of the main pump 1 communicates with the oil inlet of the hydraulic control reversing valve 2, and the first and second working oil ports of the hydraulic control reversing valve 2 correspond to the two oil ports of the rotary motor 4 one by one The oil return port of the hydraulic control reversing valve 2 communicates with the oil tank 15 to form a rotary oil circuit. The main pump 1 supplies oil to the pilot oil source valve, and the oil outlet of the main pump 1 is also connected with the oil inlet of the pilot oil source valve, and one oil outlet of the pilot oil source valve is connected with the oil inlet of the pilot handle 3, and the pilot The two pilot oil outlets of ...

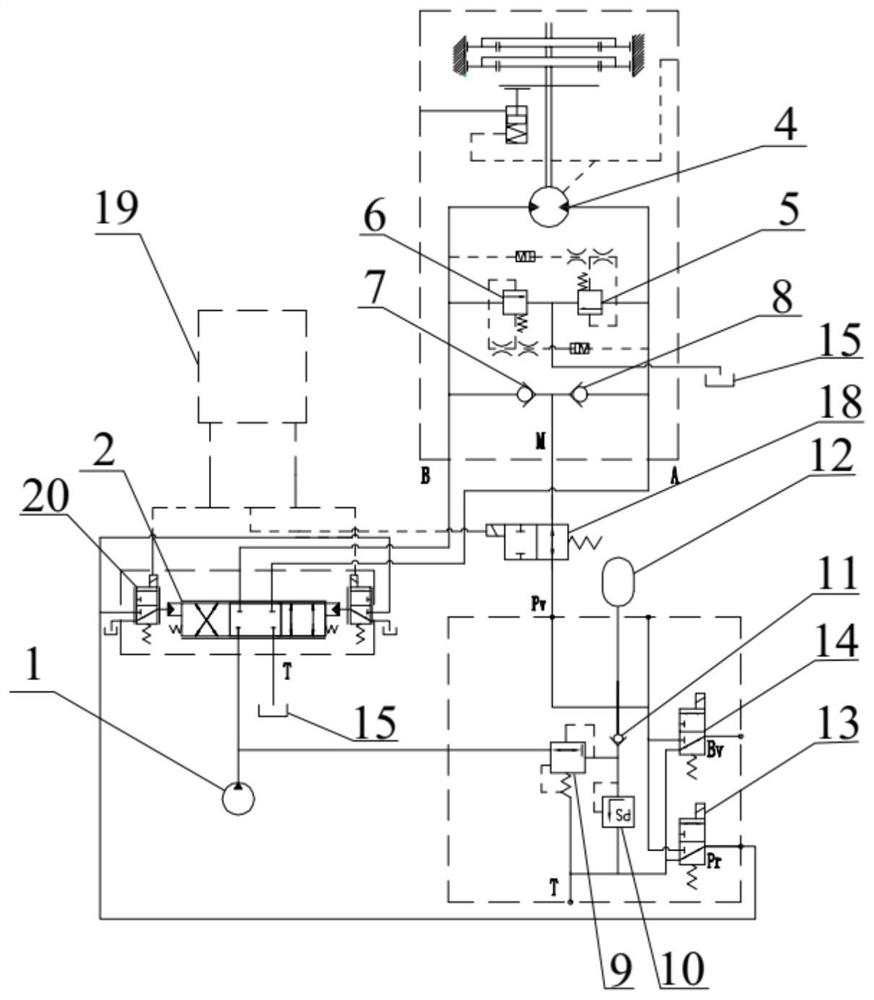

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is:

[0050] Such as image 3As shown, in the oil supply system of the rotary motor provided in this embodiment, the rotary reversing valve is an electro-hydraulic reversing valve, the control handle is an electric control handle 19, and the electric control handle 19 is electrically connected with the electro-hydraulic reversing valve for controlling The direction of the electro-hydraulic directional valve is changed, and the two liquid control ends of the electro-hydraulic directional valve are connected with an oil outlet of the pilot oil source valve. The electric control handle controls the opening of the electro-hydraulic directional valve, and the pilot oil in the pilot oil source valve enters the electro-hydraulic directional valve to push the spool of the electro-hydraulic directional valve to move, so that the hydraulic oil in the main pump 1 can be replaced by the electro-hydraulic directional valve. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com