Preparation method of 2D MOFs nanosheet-based lubricant

A base lubricant and nanosheet technology, which can be used in lubricating compositions, petroleum industry, etc., can solve the problem of high cost, and achieve the effects of low cost, easy operation and simple synthesis conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Zn(Bim)(OAc) Nanosheets

[0028] Grind 0.657g of zinc acetate dihydrate into powder and dissolve it in 30mL of base oil under ultrasonic conditions to obtain the oil phase, dissolve 2.124g of benzimidazole in 30mL of a mixed solution of 10mL of ethanol and 20mL of deionized water with a volume ratio of 1:2 to obtain an aqueous phase. Then the oil phase solution was added dropwise to the upper layer of the water phase to obtain a layered reaction solution, which was left to react at 25°C for 10 h. After the reaction, a white film was produced at the interface between the two phases, and the white film in the middle layer was obtained by filtration, dried in an air blast oven at 85°C for 17 hours, and the white powder was collected after grinding.

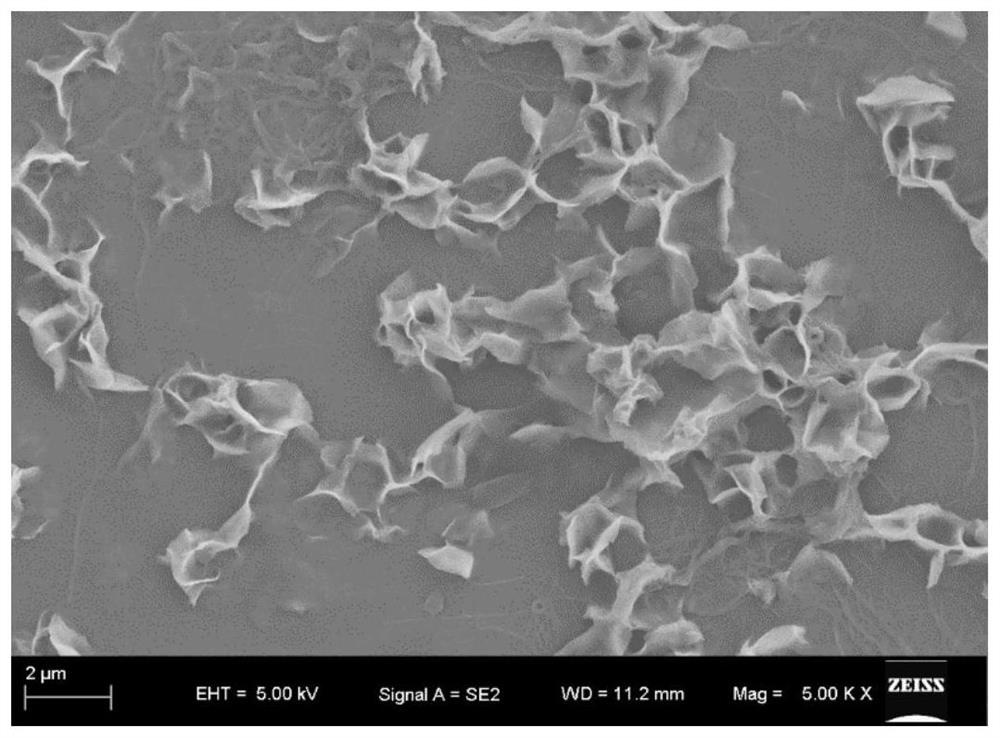

[0029] Such as figure 1 As shown in the SEM photos of the prepared Zn(Bim)(OAc) nanosheets, the thickness is about 3-4nm.

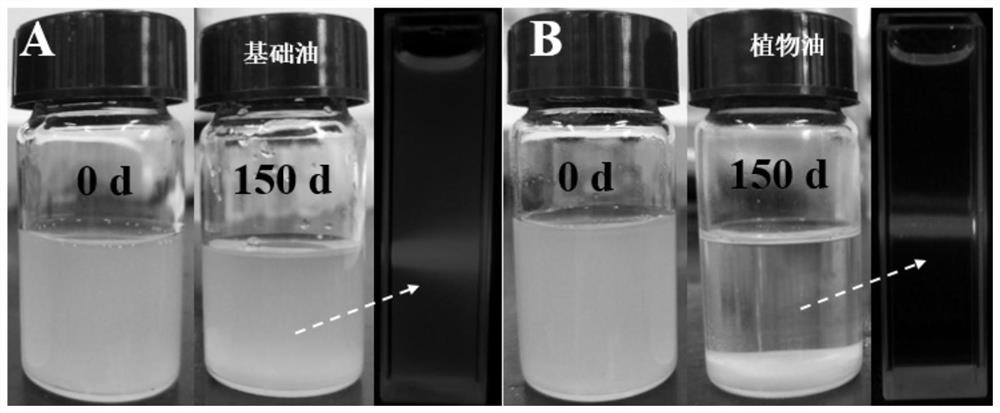

[0030] The Zn (Bim) (OAc) nanosheet that takes 0.08g is added in the 150SN base oil ...

Embodiment 2-3

[0033]Grind 0.657g of zinc acetate dihydrate into powder and dissolve it in 30mL of base oil under ultrasonic conditions to obtain the oil phase. The aqueous phase was obtained from 30 mL of the mixed solution. Then, the oil phase solution was added dropwise to the upper layer of the water phase to obtain a stratified reaction solution, which was allowed to stand at 25° C. for 10 h. After the reaction finishes, there is a white film at the two-phase interface, and the white film in the middle layer is obtained by filtration, dried in an air blast oven at 85°C for 17 hours, and the white powder is collected after grinding.

[0034] Prepare Zn(Bim)(OAc) nanosheet-based lubricant according to the method of Example 1.

[0035] The Zn(Bim)(OAc) nanosheet-based lubricants in Examples 2 and 3 can be stably dispersed in base oil for 100-120 days, but can only be stably dispersed in vegetable oil for 20-30 days.

Embodiment 4-6

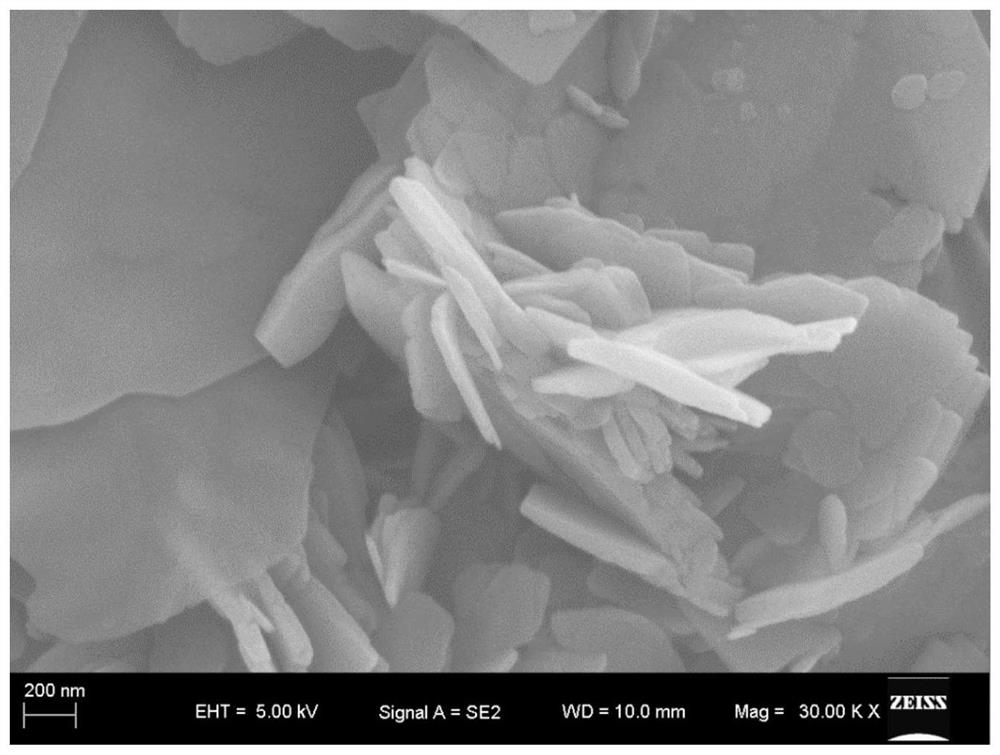

[0043] Preparation of 2D ZnBDC nanosheets

[0044] Grind 0.595g of zinc nitrate hexahydrate into powder and dissolve it in 30mL of base oil under ultrasonic conditions to obtain the oil phase, and decompose 1.992g of terephthalic acid in the volume ratio of N,N-dimethylformamide and deionized water respectively The aqueous phase was obtained from 30 mL of mixed solutions of 1:2, 1:3 and 1:6. Then the oil phase solution was added dropwise to the upper layer of the water phase to obtain a stratified reaction solution, which was allowed to stand at 25°C for 10 h. After the reaction, a white film was produced at the interface between the two phases. The white film in the middle layer was obtained by filtration, dried in a blast drying oven at 85°C for 17 hours, and the white powder 2D ZnBDC nanosheets were collected after grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com