Positive electrode material precursor and preparation method and application thereof

A positive electrode material and precursor technology, applied in the field of positive electrode material precursor and its preparation, can solve the problems of damage to the material structure, low capacity retention rate, and fragile positive electrode material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

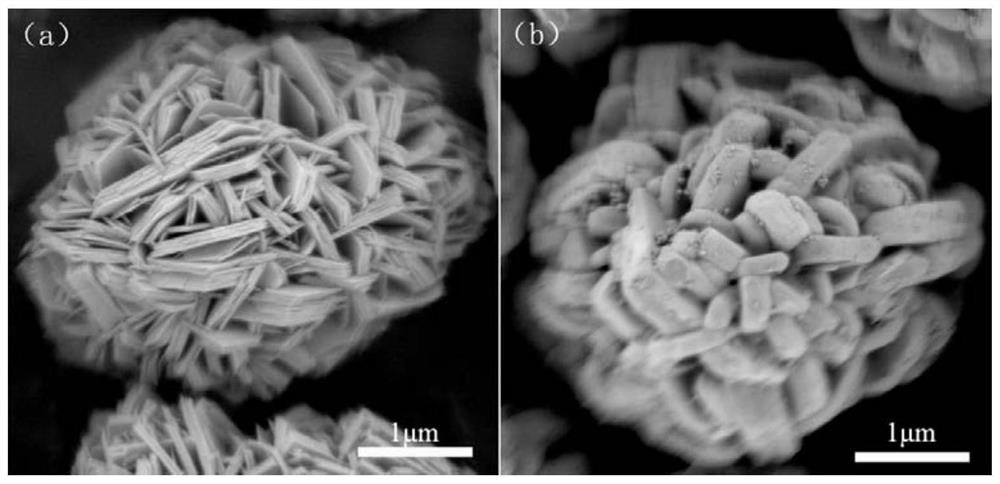

[0039] The positive electrode material precursor of the present embodiment, its chemical formula is Ni 0.5 co 0.3 mn 0.2 (OH) 2 ; The precursor is in the shape of obvious lamellar stacking, and the particle size widening coefficient of the precursor is K, K=0.75.

[0040] The preparation method of the positive electrode material precursor of the present embodiment comprises the following steps:

[0041] According to the Ni:Co:Mn molar ratio of 5:3:2, dissolve nickel sulfate, cobalt sulfate, and manganese sulfate in deionized water to prepare a metal liquid with a concentration of 0.5mol / L, and adjust the concentration of complexing agent ammonia water to 0.5g / L, and add molten metal, ammonia water, and NaOH into the reactor through a peristaltic pump, control the reaction temperature at 70°C, and stir at a speed of 200r / min. After 48 hours of reaction, switch the concentration of the molten metal to 2mol / L and to 2g / L, continue to react for 72h and then stop, and then go ...

Embodiment 2

[0052] The positive electrode material precursor of the present embodiment, its chemical formula is Ni 0.5 co 0.5 (OH) 2 ; The precursor is in the shape of obvious lamellar stacking, and the particle size widening coefficient of the precursor is 0.72, 0.72=(D v 90-D v 10) / D v 50.

[0053] The preparation method of the positive electrode material precursor of the present embodiment comprises the following steps:

[0054] According to the Ni:Co molar ratio of 5:5, nickel acetate and cobalt acetate were dissolved in deionized water to form a metal liquid with a concentration of 1mol / L, and the concentration of the complexing agent ammonia water was adjusted to 0.8g / L, and the Add molten metal, ammonia water, and NaOH into the reactor together, control the reaction temperature at 60°C, and stir at 400r / min. After 30 hours of reaction, switch the concentration of the molten metal to 1.5mol / L, and the concentration of ammonia water to 2.5g / L, and continue Stop after reacting f...

Embodiment 3

[0063] The positive electrode material precursor of the present embodiment, its chemical formula is Ni 0.2 mn 0.6 (OH) 2 ; The precursor is in the shape of obvious sheet stacking, and the particle size widening coefficient of the precursor is 0.73, 0.73=(D v 90-D v 10) / D v 50.

[0064] The preparation method of the positive electrode material precursor of the present embodiment comprises the following steps:

[0065] Dissolve nickel acetate and cobalt acetate in deionized water according to the molar ratio of Ni:Mn of 2:6, configure a metal liquid with a concentration of 0.5mol / L, adjust the concentration of complexing agent ammonia water to 2.5g / L, and pass through a peristaltic pump Add the metal liquid, ammonia water, and NaOH into the reaction kettle together, control the reaction temperature to 40°C, and the stirring speed to 100r / min. After 48 hours of reaction, switch the concentration of the metal liquid to 3mol / L, and the concentration of ammonia water to 5g / L, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com