Inorganic nonmetal pipe cutting equipment

A kind of pipe cutting equipment, inorganic non-metal technology, applied in the direction of stone processing equipment, stone processing tools, work accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

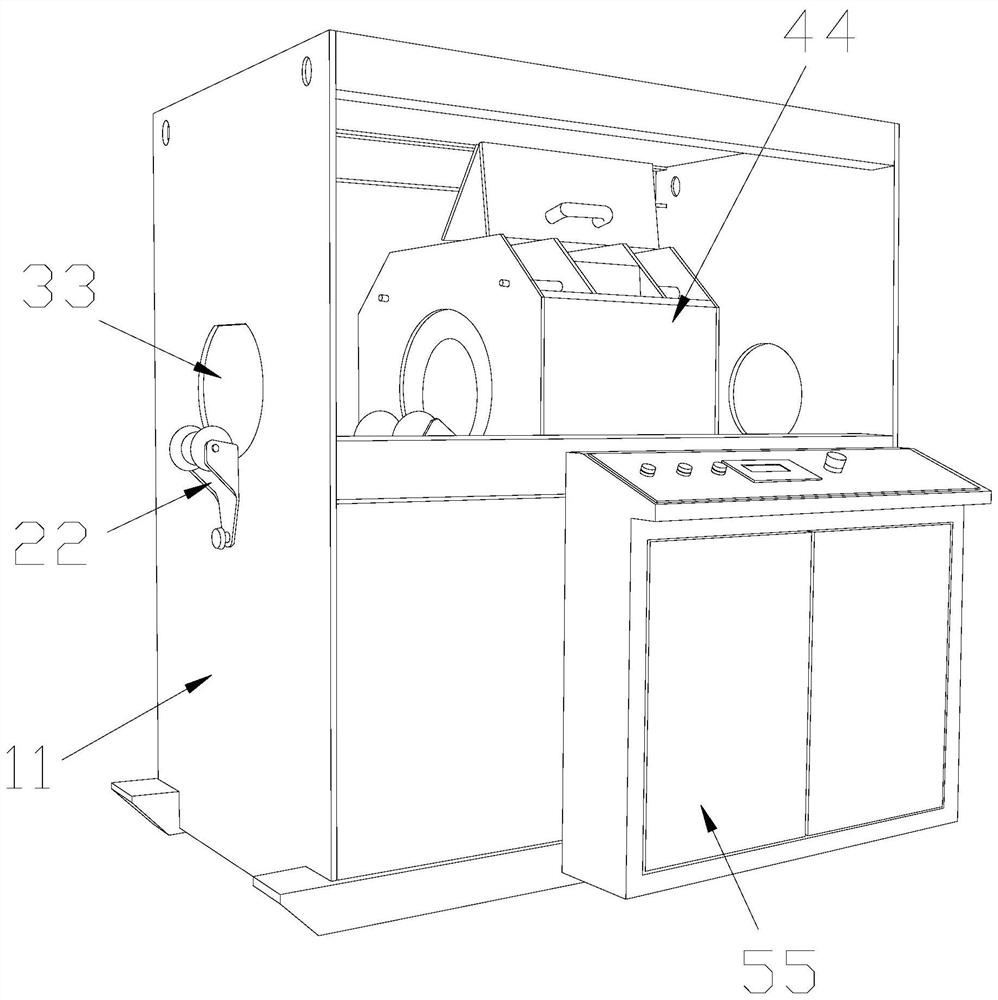

[0032] as attached figure 1 To attach Figure 6 Shown:

[0033] The present invention provides an inorganic non-metallic pipe cutting device, the structure of which includes a support plate 11, a transport wheel 22, an insertion port 33, a cutting box 44, and a control box 55. The insertion port 33 and the support plate 11 are an integrated structure. The transportation wheels 22 are installed on the outer surface of the support plates 11 , the cutting box 44 is fixedly installed between the support plates 11 , and the control box 55 is welded on the outer surface of the support plates 11 .

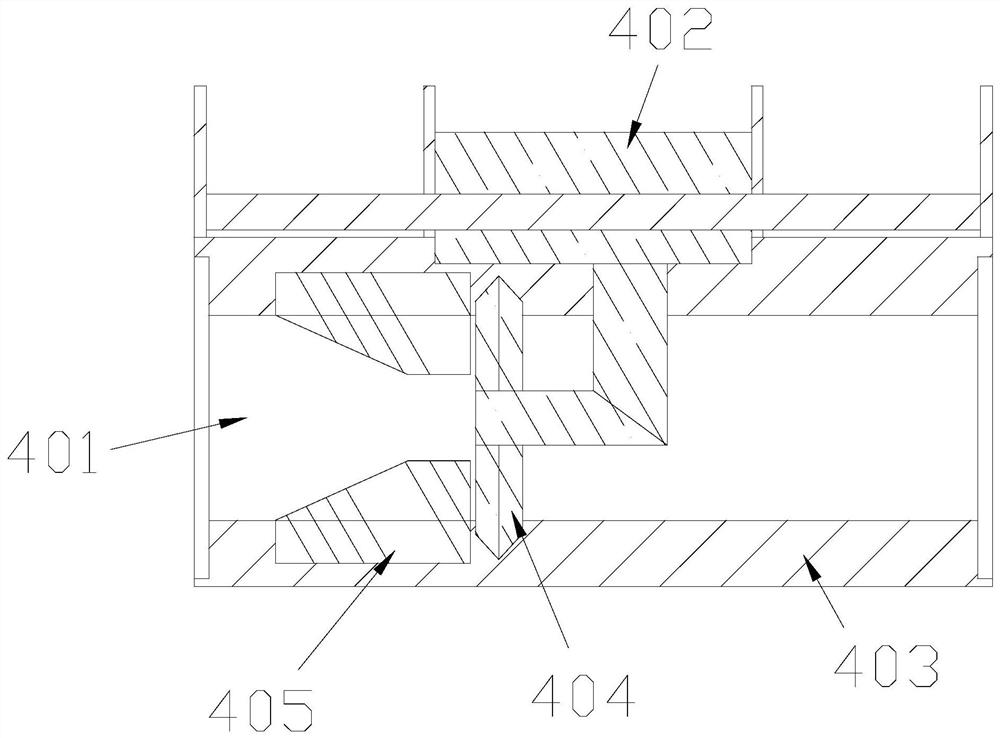

[0034] The cutting box 44 includes an insertion channel 401, a cutting control box 402, an outer limit case 403, a cutting piece 404, and an abutment ring 405. The insertion channel 401 runs through the outer limit case 403, and the abutment ring 405 is installed Inserted inside the channel 401, the cutting blade 404 and the cutting control box 402 are an integrated structure.

[0035]...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

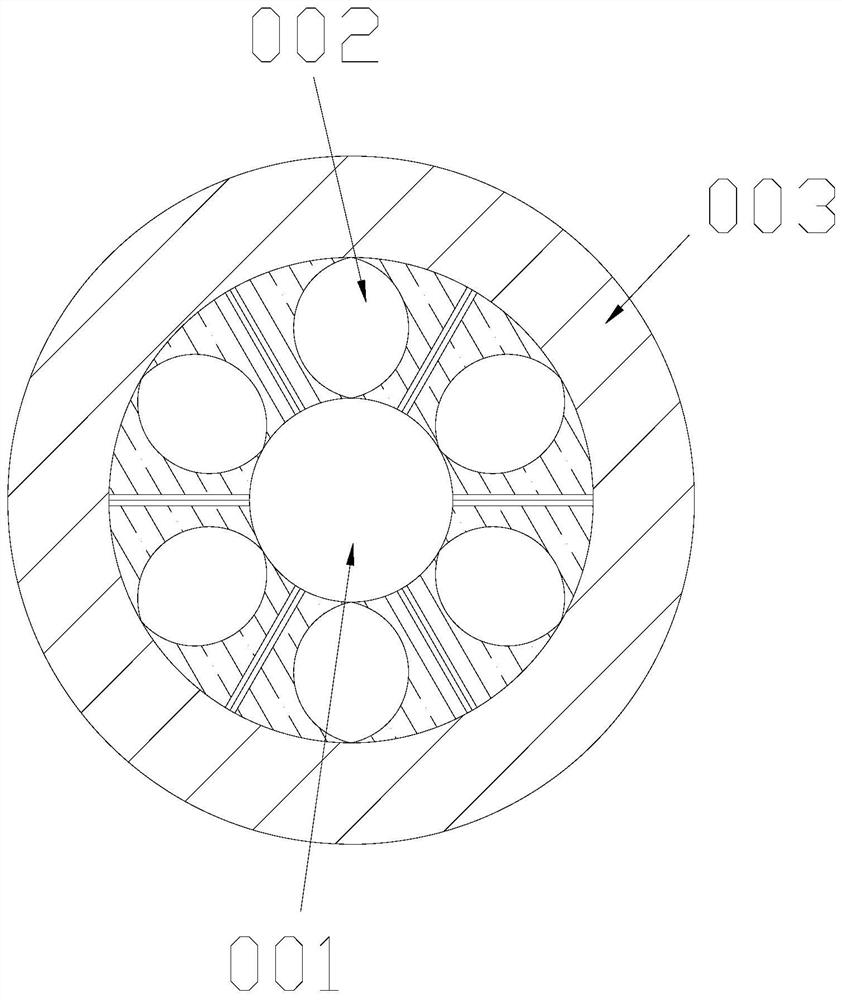

[0043] Wherein, the elastic ring 512 includes a protruding support block x11, an inner spring plate x12, and an adhesive layer x13, the inner elastic plate x12 is embedded inside the adhesive layer x13, and the outer surface of the adhesive layer x13 is equipped with a protruding support block x11, so The inner elastic plate x12 itself is made of elastic material and distributed symmetrically. There are four protrusions x11. The rubber layer x13 is made of rubber material. When the overall force is applied to the rubber layer x13, it will Appropriately deformed, the protrusion x11 allows the outer layer to have a certain undulation range, which can better resist the textured surface, and the inner elastic plate x12 continues to maintain a state of expansion, and will only bend when a force is applied.

[0044] Wherein, the protruding block x11 includes a header m11, an arc m12, and an elastic strip m13. The header m11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com