Magnetic nano material as well as preparation method and application thereof

A magnetic nanometer and nanoparticle technology, applied in the field of nanomaterials, can solve the problems of demanding demulsification temperature, slow demulsification speed, and limited popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

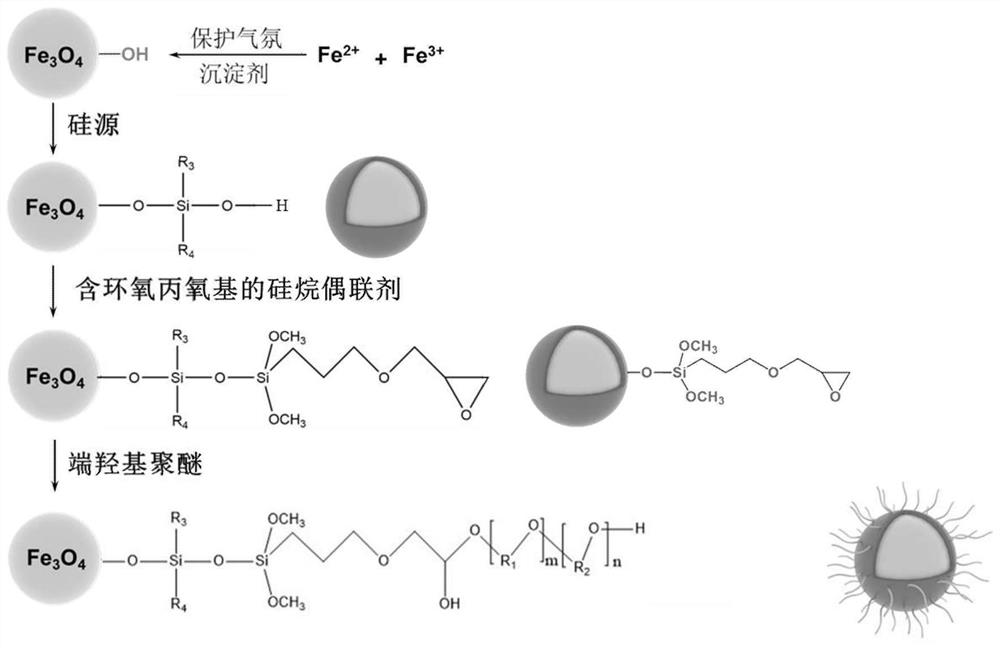

[0107] This embodiment provides a magnetic nanomaterial, the magnetic nanomaterial includes a magnetic core of ferroferric oxide, the outer side of the magnetic core is coated with a layer of silica shell, and the outer side of the silica shell is grafted as shown in the formula (1) the organic group shown;

[0108]

[0109] R in formula (1) 1 for -CH 2 -CH 2 -, R 2 for -CH 2 (CH 3 )CH-;

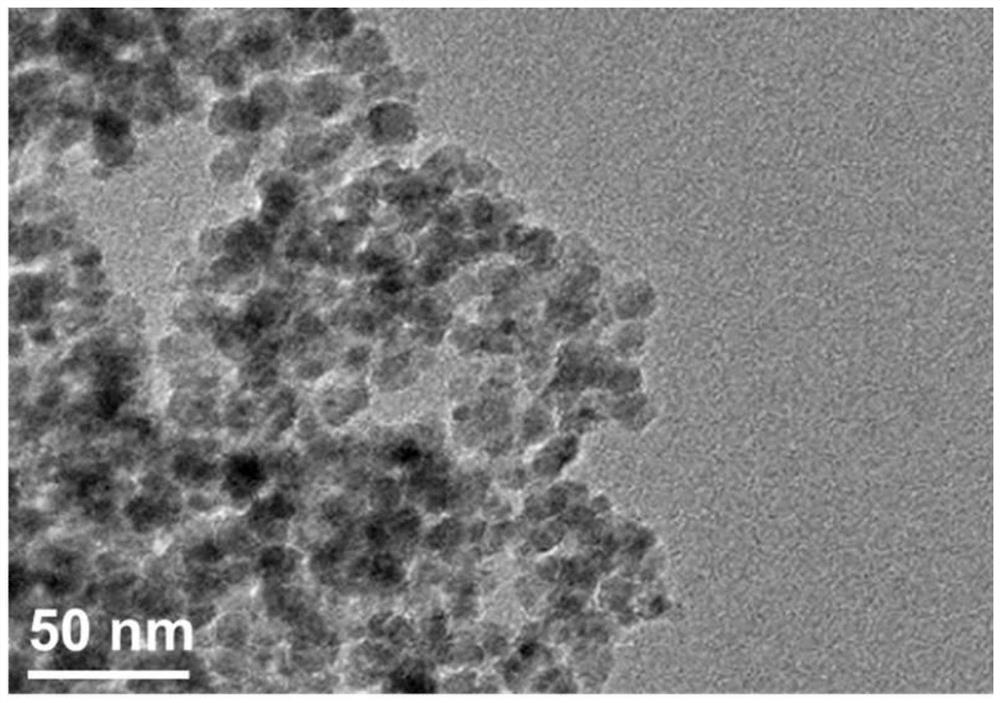

[0110] The average particle diameter of the magnetic nanomaterial is 9nm, and the silica shell is a group shown in formula (2):

[0111]

[0112] R described in formula (2) 3 and R 4 are each independently O- or OH.

[0113] This embodiment also provides a preparation method of the magnetic nanomaterial, the preparation method comprising the following steps:

[0114] (1) Weigh 0.44g FeCl 2 4H 2 O and 1.10 g FeCl 3 ·6H 2 O was dissolved in 50mL deionized water, the temperature of the solution was adjusted to 60°C, and 20mL of ammonia water (5wt%) was slowly added dropwise ...

Embodiment 2

[0122] This embodiment provides a magnetic nanomaterial, the magnetic nanomaterial includes a magnetic core of ferroferric oxide, the outer side of the magnetic core is coated with a layer of silica shell, and the outer side of the silica shell is grafted as shown in the formula (1) the organic group shown;

[0123]

[0124] R in formula (1) 1 for -CH 2 -CH 2 -, R 2 for -CH 2 (CH 3 )CH-;

[0125] The average particle diameter of the magnetic nanomaterial is 9.5nm, and the silica shell is a group shown in formula (2):

[0126]

[0127] R described in formula (2) 3 and R 4 are each independently O- or OH.

[0128] This embodiment also provides a preparation method of the magnetic nanomaterial, the preparation method comprising the following steps:

[0129] (1) Weigh 0.43g Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O and 0.40g Fe 2 (SO 4 ) 3 Dissolve in 50mL of deionized water, adjust the temperature of the solution to 60°C, slowly add 25mL of ammonia water (5wt%) dropwise...

Embodiment 3

[0134] This embodiment provides a magnetic nanomaterial, the magnetic nanomaterial includes a magnetic core of ferroferric oxide, the outer side of the magnetic core is coated with a layer of silica shell, and the outer side of the silica shell is grafted as shown in the formula (1) the organic group shown;

[0135]

[0136] R in formula (1) 1 for -CH 2 -CH 2 -, R 2 for -CH 2 (CH 3 )CH-;

[0137] The average particle diameter of the magnetic nanomaterial is 8.6nm, and the silica shell is a group shown in formula (2):

[0138]

[0139] R described in formula (2) 3 and R 4 each independently O- or CH 3 O-.

[0140] This embodiment also provides a preparation method of the magnetic nanomaterial, the preparation method comprising the following steps:

[0141] (1) Weigh 0.44g FeCl 2 4H 2 O and 1.10 g FeCl 3 ·6H 2 Dissolve O in 50mL deionized water, adjust the temperature of the solution to 60°C, and slowly add 10mL sodium hydroxide solution (0.10mol / L) dropwise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com