Manufacturing process of insect specimen

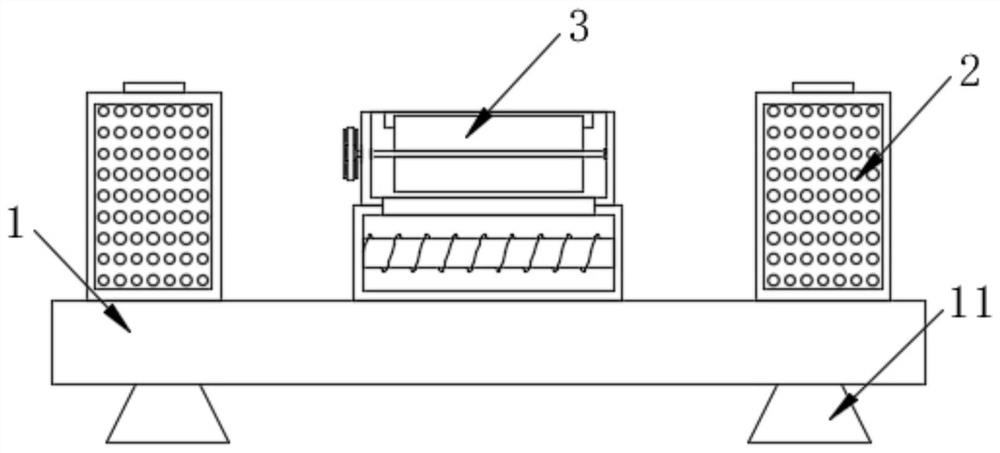

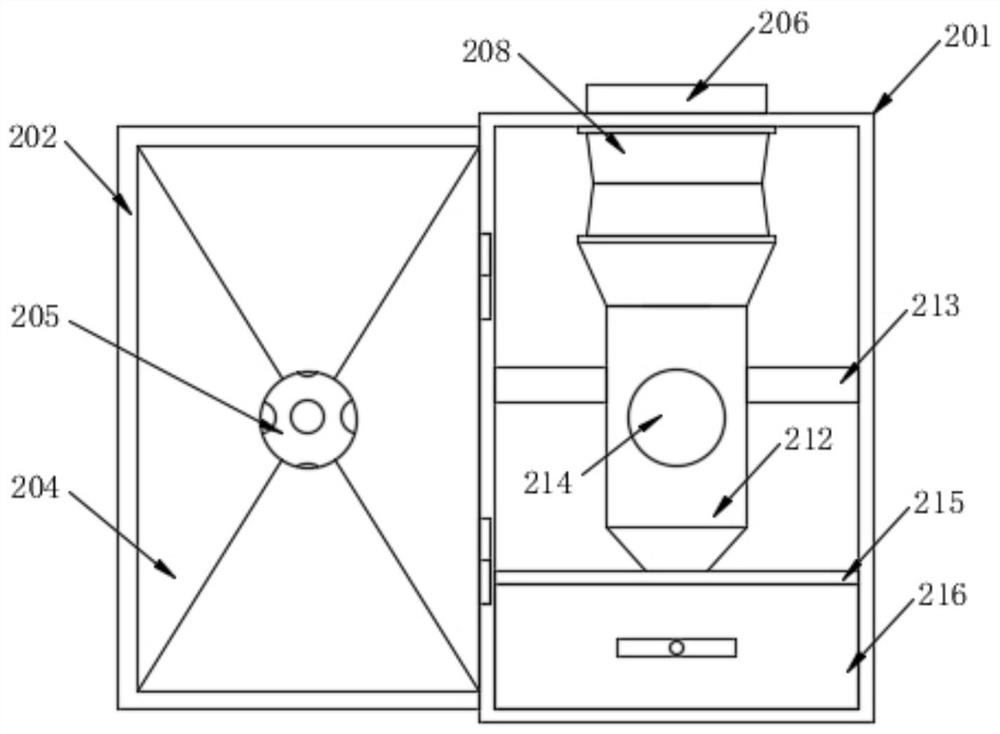

A technology for making crafts and insects, which is applied in the field of making insect specimens, and can solve problems such as inability to capture insects, poor insect catching effect, and slow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A manufacturing process of an insect specimen, comprising the steps of:

[0049] Step 1, collect information, collect information on the natural living environment and habits of insects, measure and record the body length, weight, tail length and limb length of insects;

[0050] Step 2, catching insects, using the insect catching device to capture insects, and putting the captured insects into poison bottles for poisoning;

[0051] Step 3, antisepsis, put the poisoned insects into 95% ethanol for alcohol disinfection, kill microorganisms and carry out antisepsis;

[0052] Step 4, shaping, fixing the insect with a triangular belt, and continuing to shape the shape of the insect according to the shape and size of the insect before its death;

[0053] Step 5, drying, placing the insects at a temperature of 50°C for 20 minutes;

[0054] Step 6. Re-softening, put the dried insects in a re-softening container, and add 10ml of carbolic acid dropwise for re-softening, and the...

Embodiment 2

[0061] A manufacturing process of an insect specimen, comprising the steps of:

[0062] Step 1, collect information, collect information on the natural living environment and habits of insects, measure and record the body length, weight, tail length and limb length of insects;

[0063] Step 2, catching insects, using the insect catching device to capture insects, and putting the captured insects into poison bottles for poisoning;

[0064] Step 3, antisepsis, put the poisoned insects into 95% ethanol for alcohol disinfection, kill microorganisms and carry out antisepsis;

[0065] Step 4, shaping, fixing the insect with a triangular belt, and continuing to shape the shape of the insect according to the shape and size of the insect before its death;

[0066] Step 5, drying, drying the insects at a temperature of 60°C for 25 minutes;

[0067] Step 6. Re-softening, put the dried insects in a re-softening container, and add 15ml of carbolic acid dropwise for re-softening, and the ...

Embodiment 3

[0074] A manufacturing process of an insect specimen, comprising the steps of:

[0075] Step 1, collect information, collect information on the natural living environment and habits of insects, measure and record the body length, weight, tail length and limb length of insects;

[0076] Step 2, catching insects, using the insect catching device to capture insects, and putting the captured insects into poison bottles for poisoning;

[0077] Step 3, antisepsis, put the poisoned insects into 95% ethanol for alcohol disinfection, kill microorganisms and carry out antisepsis;

[0078] Step 4, shaping, fixing the insect with a triangular belt, and continuing to shape the shape of the insect according to the shape and size of the insect before its death;

[0079] Step 5, drying, placing the insects at a temperature of 70°C for 30 minutes;

[0080] Step 6. Re-softening. Put the dried insects in a re-softening container, and add 20ml of carbolic acid dropwise for re-softening. The re-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com