Hybrid Schottky barrier diode structure with P-type nickel oxide material

A Schottky potential, hybrid technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of narrow current channel, high breakdown voltage, increase forward conduction resistance of devices, etc., to reduce forward conduction Resistance, large forward current density, solving the effect of difficult acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

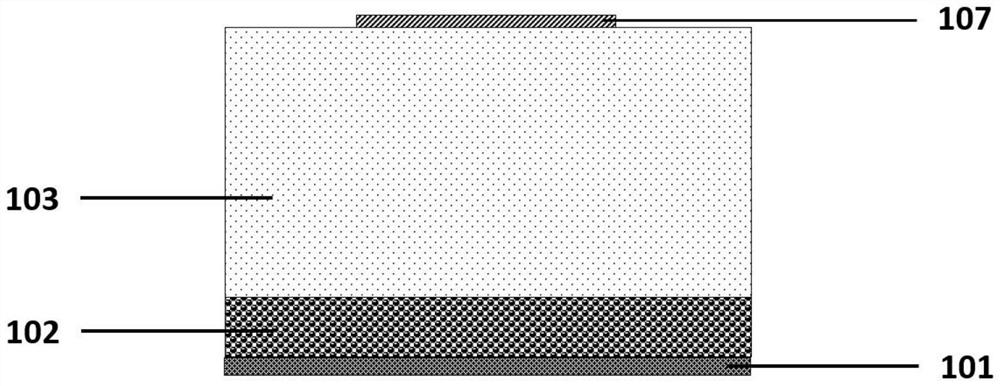

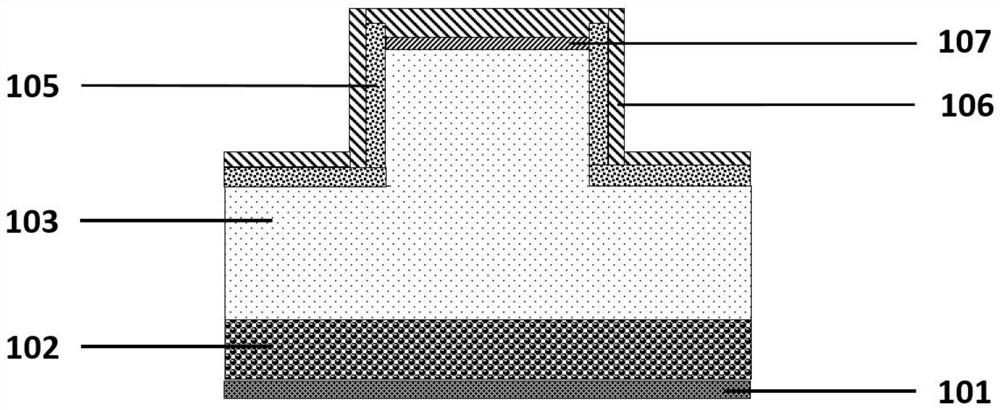

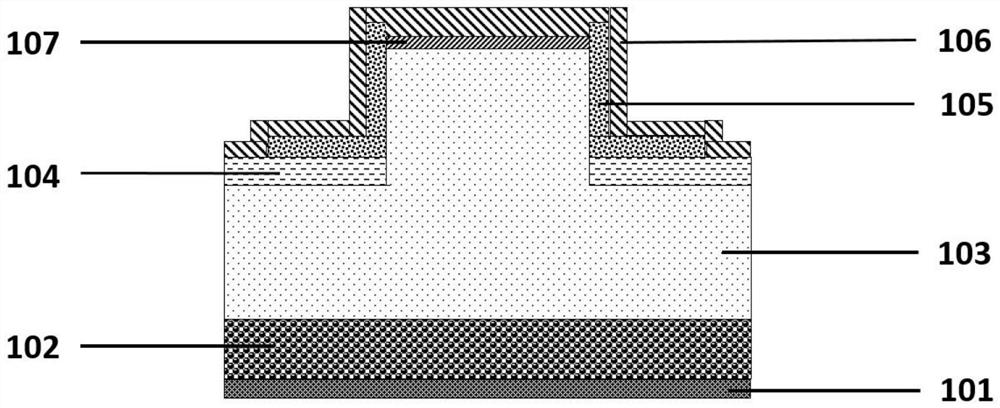

[0060] This embodiment adopts the structure of a hybrid Schottky barrier diode with p-type nickel oxide (p-NiO) material as image 3 shown. The device structure along the epitaxial direction is as follows: bottom ohmic contact electrodes 101, N + Substrate 102, N - drift layer 103, wherein, N - The drift layer 103 has protrusions arranged in an array, a single protrusion is a middle protrusion, a step structure, and the projected area of the protrusion part is all N - 35% of the area of the drift layer 103; the N of the raised part - On the drift layer 103 is a Schottky contact electrode 107; the N of the non-protruding part -The drift layer 103 is covered with a p-type layer 104, and the inner side of the upper surface of the p-type layer 104 is a field plate dielectric layer 105 (the projected area of the field plate dielectric layer 105 is 70% of the upper surface of the p-type layer 104), N - The side wall of the raised part of the drift layer 103 is also covere...

Embodiment 2

[0090] This embodiment adopts the structure of a hybrid Schottky barrier diode with p-type nickel oxide (p-NiO) material as Figure 6 As shown, the difference between this structure and the structure in Example 1 is that side wall field plate structures are provided on both sides of the p-NiO layer. The sidewall field plate structure is formed after the first ICP dry etching - The outer edges on both sides of the upper surface of the non-protruded part of the drift layer 103 are again subjected to ICP dry etching to form a second shallow step structure on the outer surface. The device structure along the epitaxial direction is as follows: bottom ohmic contact electrodes 101, N + Substrate 102, N - drift layer 103, wherein, N - The drift layer 103 is a two-layer stepped structure with a raised middle, and the area of the lowest groove is the entire N - 25% of the area of the drift layer 103 (that is, the projected area of the two layers of raised parts is all N - 75%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com