Two-stage asymmetric directional coupler-type optical polarization beam splitting rotator connected by u-shaped waveguide

A technology of directional coupler and polarization beam splitting, which is applied in the direction of optical waveguide light guide, instrument, optics, etc., can solve the problems of small device manufacturing tolerance, high overall performance, and large loss, so as to improve the manufacturing tolerance and solve the extinction ratio Low, the effect of improving the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

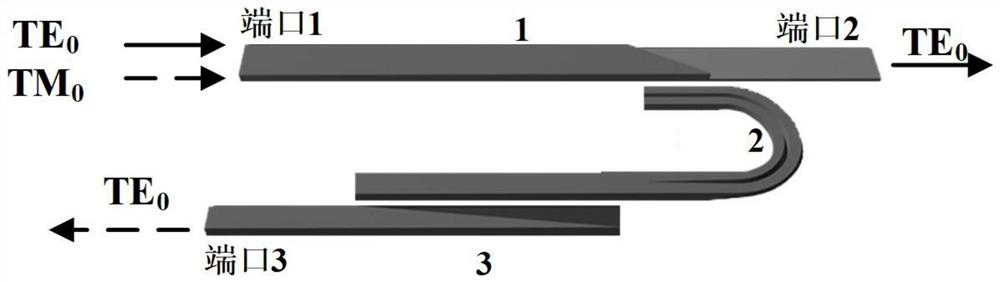

[0036] The present invention is a two-stage asymmetric directional coupler type optical polarization beam splitting rotator connected by a U-shaped waveguide. Such as figure 1 As shown, both the substrate and the upper cladding are made of silicon dioxide; silicon is used as the main body of the polarization beam splitting rotator.

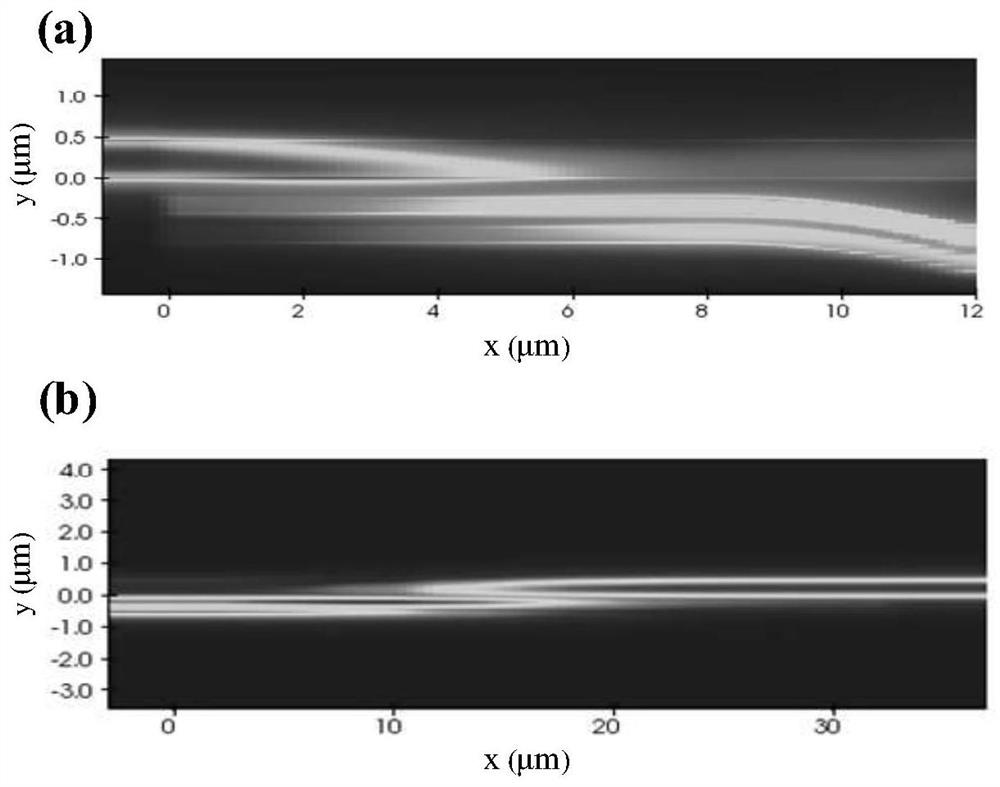

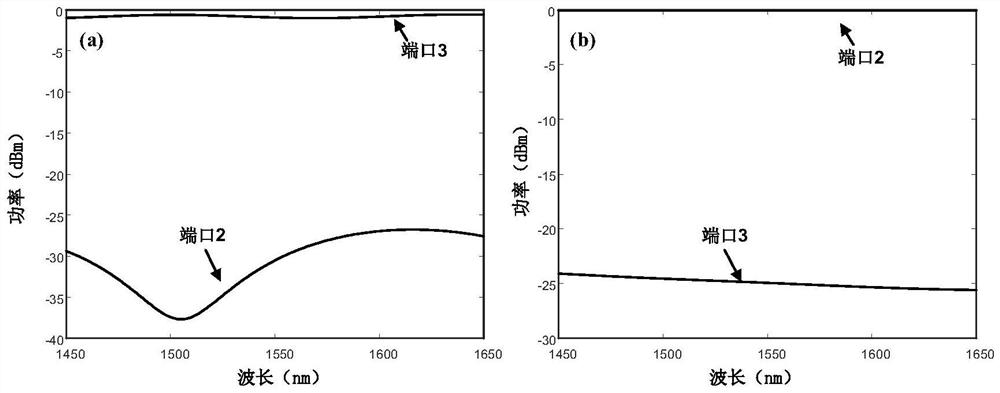

[0037] The overall structure of the device is divided into three parts: the waveguide 1 is a tapered etched waveguide, the etching depth is selected as 70nm according to the process requirements, and the polarization effective refractive index condition that can be coupled with the waveguide 2 is constructed by etching; the waveguide 2 It is a U-shaped waveguide, connecting waveguide 1 and waveguide 3, with a preset distance from waveguide 1, and its structure can be divided into three section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com