Power swing arm mechanism of cutting machine and cutting machine

A cutting machine and power technology, which is applied in the field of power swing arm mechanism and cutting machine, can solve the problems of motor and electrical components damage, escape, and difficulty in dynamic sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

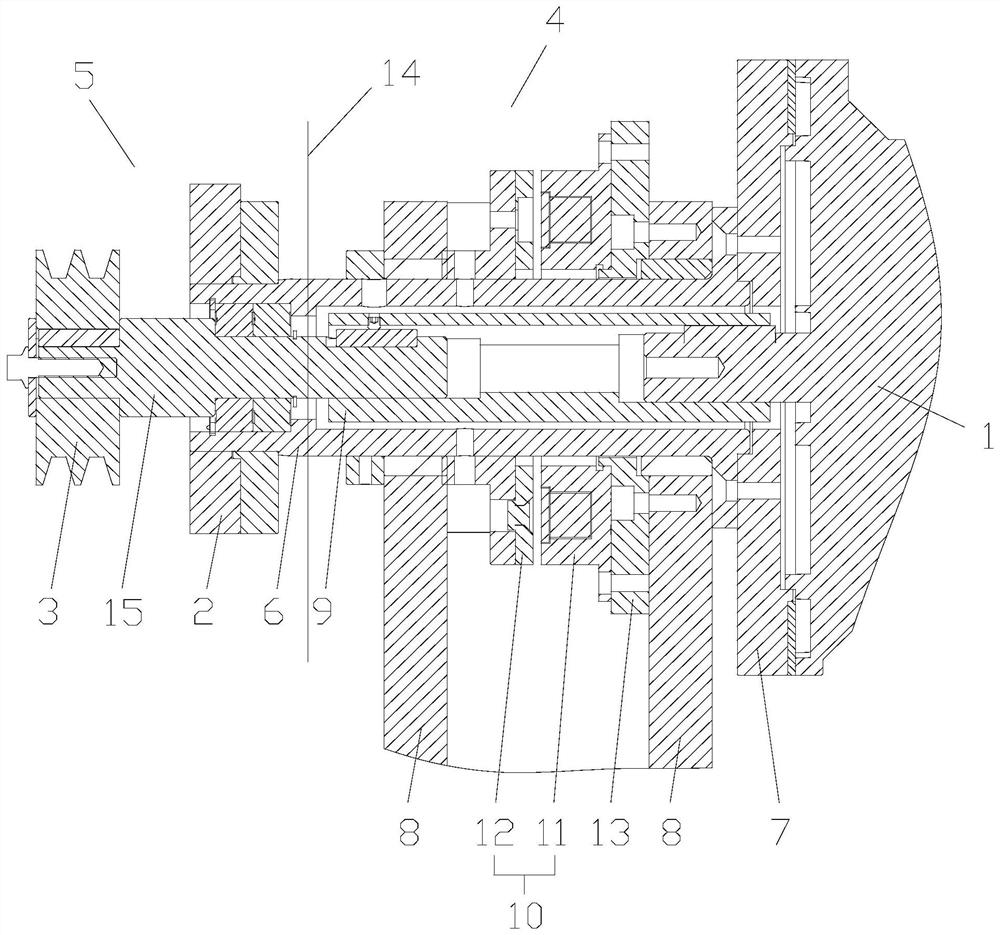

[0020] see figure 1 , the present invention provides a power swing arm mechanism of a cutting machine, which is arranged on a cutting machine with a dry cabin 4 and a wet cabin 5 .

[0021] The power swing arm mechanism of the cutting machine comprises a motor 1, a handle, a swing arm 2, a driving wheel 3, a driven wheel and a transmission belt.

[0022] The motor 1 is arranged in the dry chamber 4 and is rotatably connected to the cutting machine. The rotating shaft of the motor 1 extends to the wet chamber 5 . The swing arm 2 is fixedly connected with the motor 1 . The driving wheel 3 is coaxially fixed with the rotating shaft, and the driven wheel is rotatably arranged on the swing arm 2 for fixing the cutting blade, and the driven wheel and the driving wheel 3 are connected by a transmission belt. The handle is fixed on the motor 1 for driving the motor 1 to rotate.

[0023] Motor 1 is arranged in the dry cabin 4, has prevented the water vapor erosion in the wet cabin ...

Embodiment 2

[0029] see figure 1 , a cutting machine, including the power swing arm mechanism of the cutting machine as described in Embodiment 1, and also includes a dry cabin 4 and a wet cabin 5. The dry compartment 4 and the wet compartment 5 are separated by a partition 14, and a through hole is provided on the partition 14, and a sealing ring is provided on the through hole.

[0030] One end of the sleeve flange 6 is fixedly connected with the motor 1 in the dry compartment 4, and the other end is fixedly connected with the driving wheel 3 through the through hole on the partition plate 14, and the outer wall of the sleeve flange 6 is sealed with the through hole. Ring interference fit, so that there is no gap between the dry cabin 4 and the wet cabin 5, further preventing the possibility of fog entering the dry cabin 4.

[0031] In summary, the present invention can greatly reduce the sealing difficulty of the wet and dry cabin 5, and prevent the wet cabin 5 from eroding water mist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com