Pulverized coal boiler direct-fired biomass drying system and drying method

A pulverized coal boiler and drying system technology, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc., can solve the problems of biomass mixing and other problems, and achieve the effect of avoiding spontaneous combustion and extremely easy spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the present invention will be described in further detail below in conjunction with the examples.

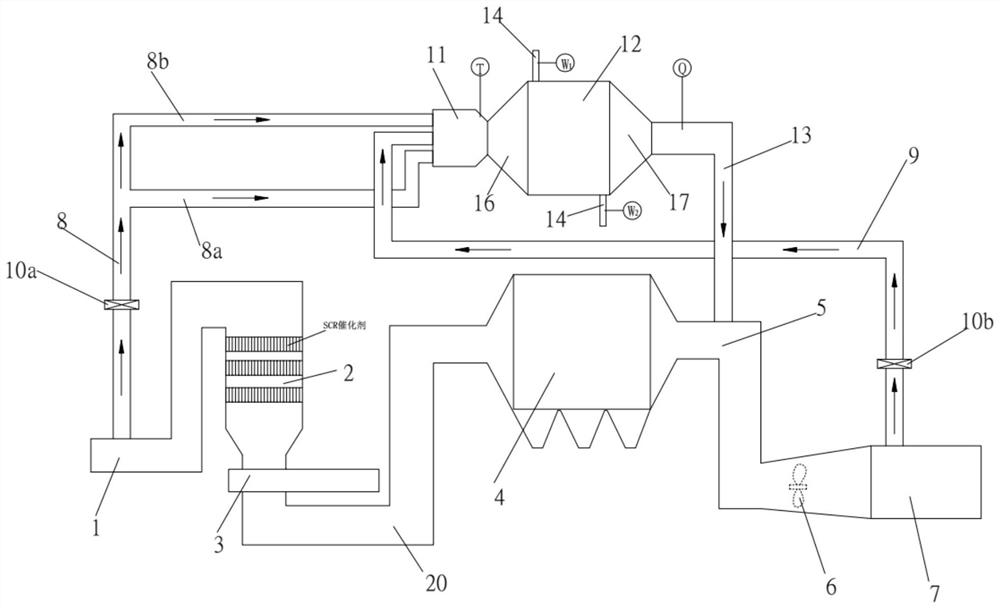

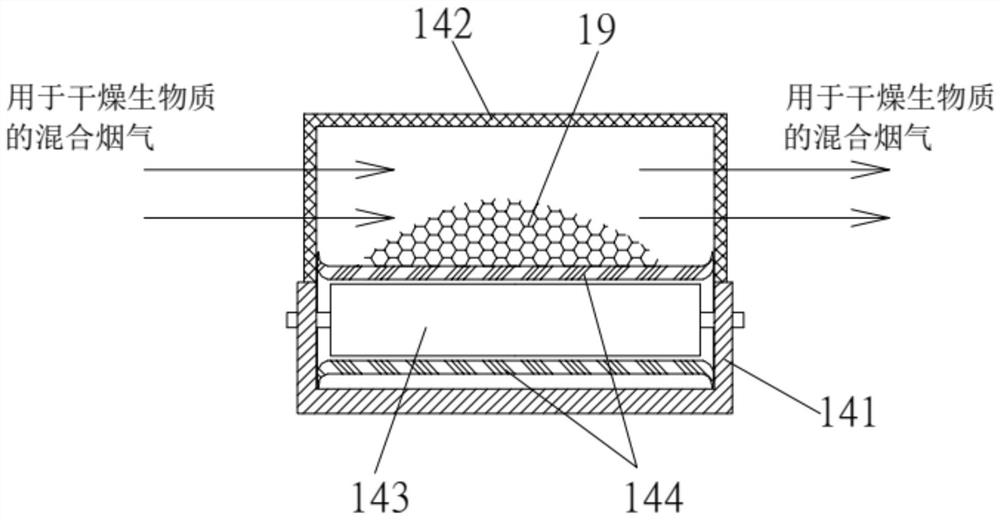

[0033] Depend on Figure 1-4 Given, a pulverized coal boiler direct-fired biomass drying system of the present invention includes SCR inlet flue 1, SCR reactor 2, SCR outlet flue 20, induced draft fan inlet flue 5 and induced draft fan outlet flue connected in sequence 7. The pulverized coal boiler direct-fired biomass drying system also includes a conveyor belt 14 for feeding the biomass 19 into the coal mill entrance for pulverization and a drying system for drying the biomass on the conveyor belt 14;

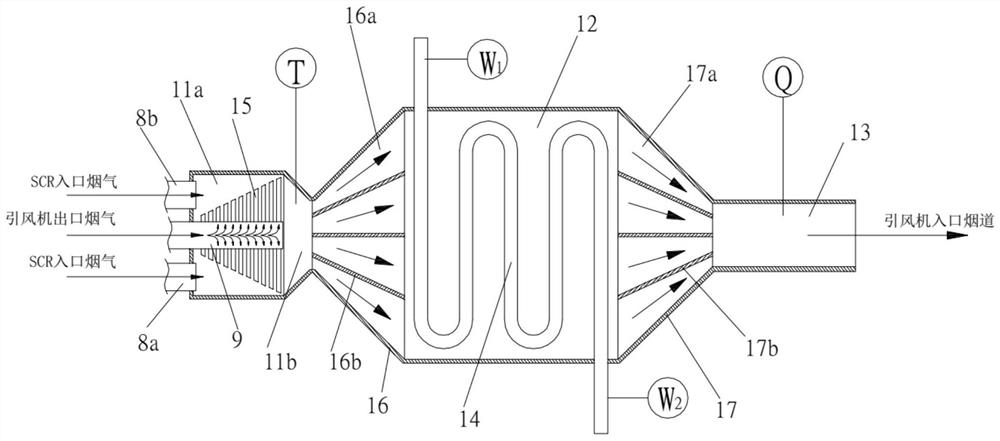

[0034] The drying system includes a flue gas mixing chamber 11 and a drying chamber 12 connected in sequence, and the flue gas mixing chamber 11 includes a jet mixing chamber 11a and a shrinking mixing chamber 11b connected in sequence, and the inner cavity of the shrinking mixing chamber 11b is formed into a constricted shape, One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com