Device for converting low-calorific value fuel into clean thermal energy

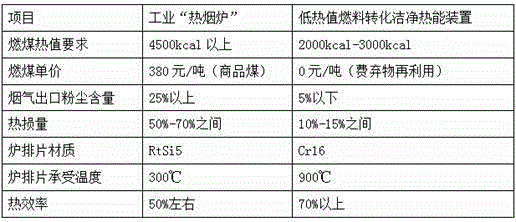

A technology of fuel conversion and low calorific value, which is used in the safety device of the combustion chamber, fuel supply, and combustion of solid fuel, etc., can solve the problems of waste of resources, obvious damage to downstream equipment along the process, and large heat loss, and achieve market prospects. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the examples.

[0040] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The parts, equipment and materials used are not indicated by the manufacturer, but they are all conventional products that can be obtained through purchase.

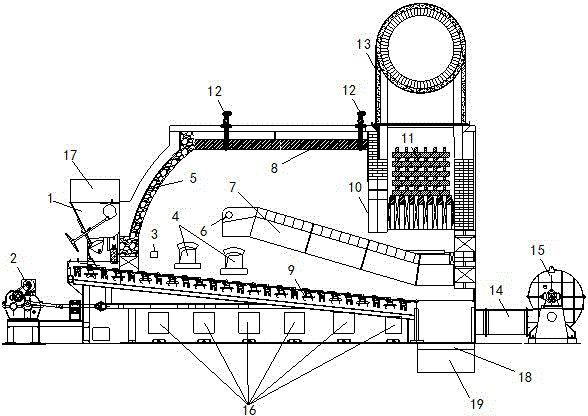

[0041] Such as figure 1 As shown, a clean heat energy conversion device suitable for low calorific value fuels includes a furnace body and an air induction pipe 13 connected to the furnace body. The furnace body has three arch walls, namely the front arch 5, the upper arch 8 and the rear arch 7. There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com