Environment-friendly nano-planting agent used before coating for prestressed steel strand, and use process

A kind of prestressed steel strand, environmental protection technology, applied in the direction of metal material coating process, etc., can solve the problems of low efficiency in production process, waste water discharge and environmental pollution, etc., and achieve the effect of improving compactness and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

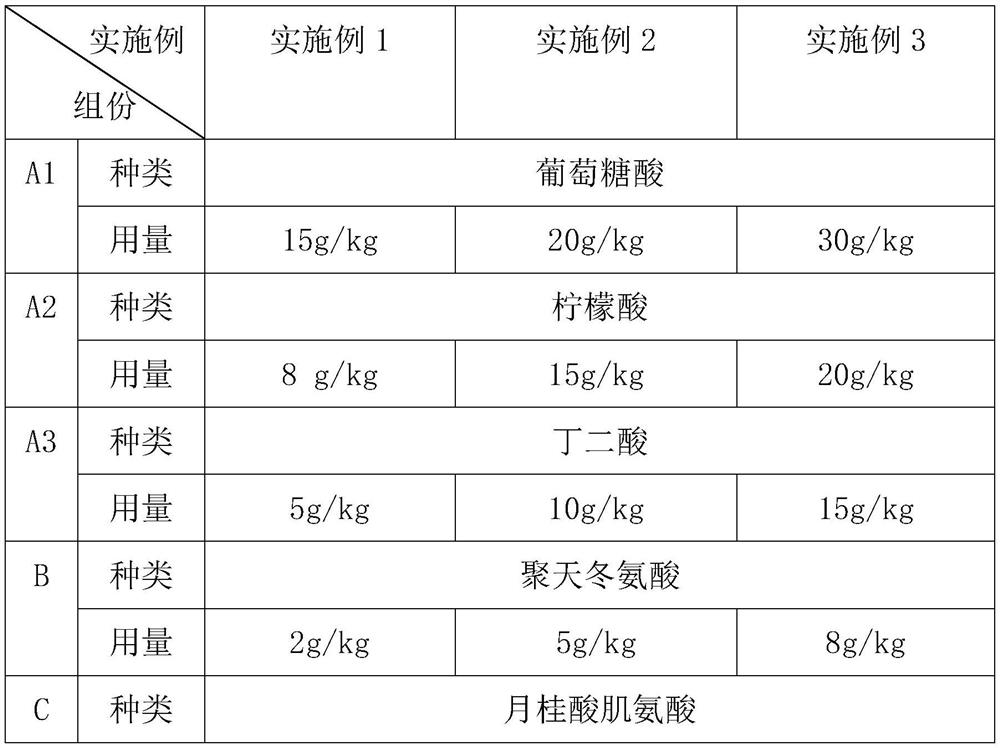

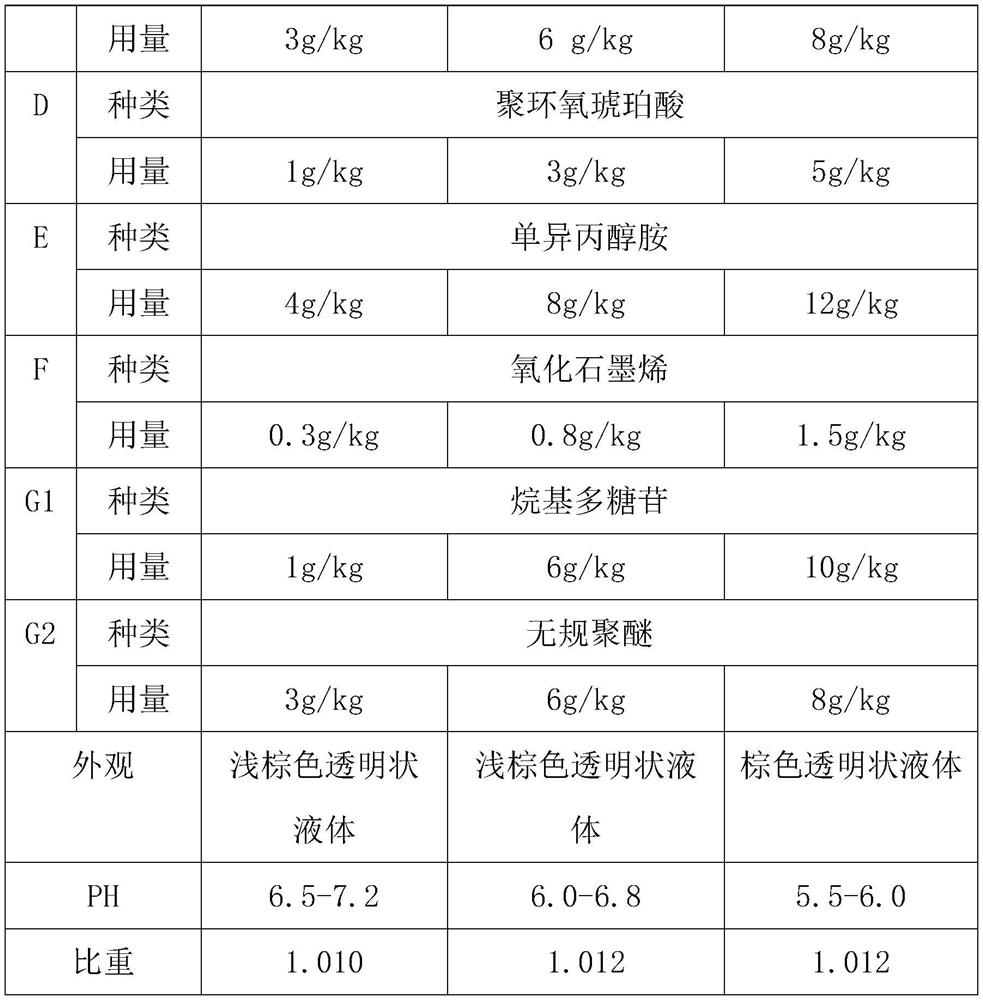

[0045] Environmentally-friendly nano-phytochemicals used for prestressed steel strands before coating, each 1Kg of environmentally-friendly nano-phytochemicals are made from the following raw materials in weight ratio: 28g of vegetable acid mixture, 2g of chelating dispersant , Chelating film forming agent 3g, film forming corrosion inhibitor 1g, pH regulator 4g, pore sealing agent 0.3g, compound low foam surfactant 4g and deionized water balance.

[0046] In the embodiment of the present invention, the plant acid mixture is composed of 15g gluconic acid, 8g citric acid and 5g succinic acid, and the compound low-foaming surfactant is composed of 1g alkyl polyglucoside and 3g random polyether. Ionized water is deionized water with conductivity ≤5μS / cm.

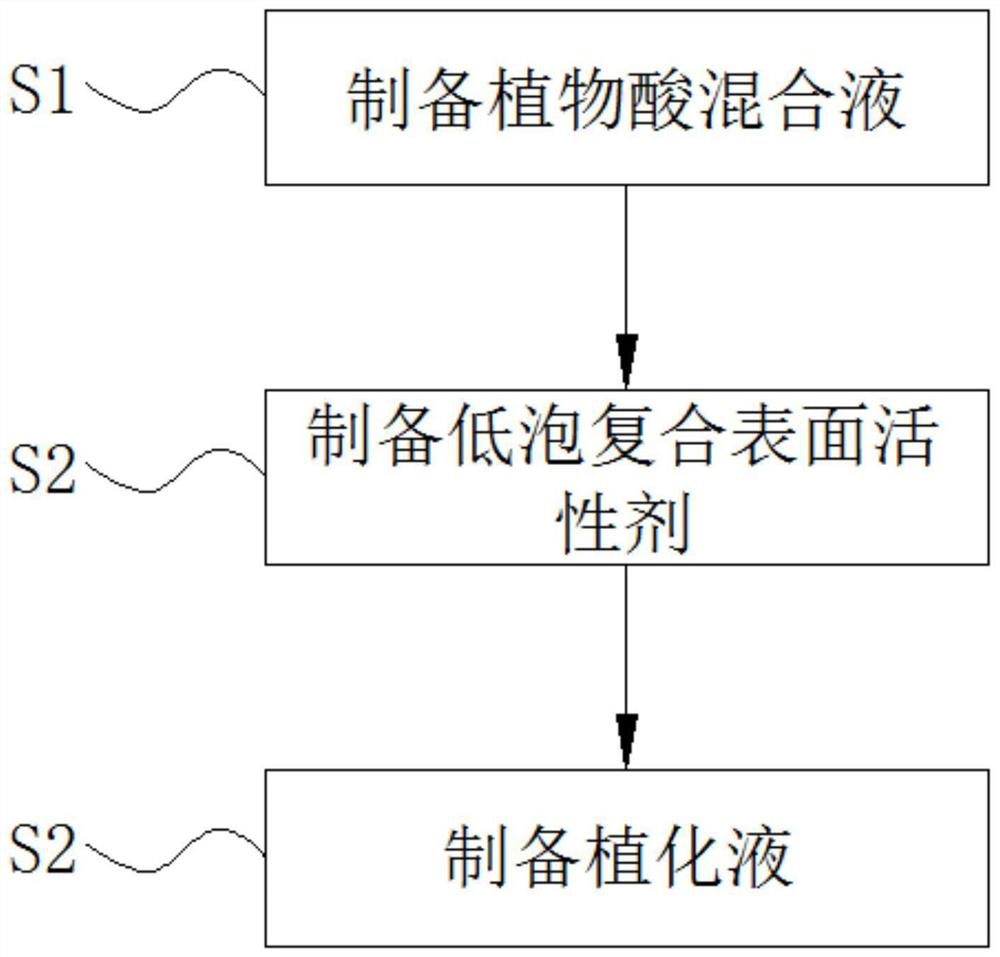

[0047] The embodiment of the present invention also provides a preparation method of an environment-friendly nano-phytochemical agent for prestressed steel strands before coating, which specifically includes the following steps...

Embodiment 2

[0059] Environmentally-friendly nano-phytochemical agent used for prestressed steel strands before coating, each 1Kg of environmentally-friendly nano-phytochemical agent is made from the following raw materials in weight ratio: plant acid mixture 45g, chelating dispersant 5g , 6 g of chelating film forming agent, 3 g of film forming corrosion inhibitor, 8 g of pH regulator, 0.8 g of pore sealing agent, 12 g of composite low foaming surfactant and the balance of deionized water.

[0060] In the embodiment of the present invention, the plant acid mixture is composed of 20g gluconic acid, 15g citric acid and 10g succinic acid, and the compound low-foaming surfactant is composed of 6g alkyl polyglucoside and 6g random polyether. Ionized water is deionized water with conductivity ≤5μS / cm.

[0061] The embodiment of the present invention also provides a preparation method of an environment-friendly nano-phytochemical agent for prestressed steel strands before coating, which specific...

Embodiment 3

[0073] Environmentally-friendly nano-phytochemical agent used for prestressed steel strands before coating, each 1Kg of environmentally-friendly nano-phytochemical agent is made from the following raw materials in weight ratio: plant acid mixture 65g, chelating dispersant 8g , Chelating film forming agent 8g, film forming corrosion inhibitor 5g, pH regulator 12g, pore sealing agent 1.5g, compound type low foaming surfactant 18g and deionized water balance.

[0074] In the embodiment of the present invention, the plant acid mixture is composed of 30g gluconic acid, 20g citric acid and 15g succinic acid, and the compound low-foaming surfactant is composed of 10g alkyl polyglucoside and 8g random polyether. Ionized water is deionized water with conductivity ≤5μS / cm.

[0075] The embodiment of the present invention also provides a preparation method of an environment-friendly nano-phytochemical agent for prestressed steel strands before coating, which specifically includes the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com