Bi-component conductive silica gel as well as preparation method and application thereof

A conductive silicone, two-component technology, applied in the field of conductive adhesive, can solve the problem of large heat dissipation, and achieve the effect of improving shielding efficiency, excellent shielding efficiency and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

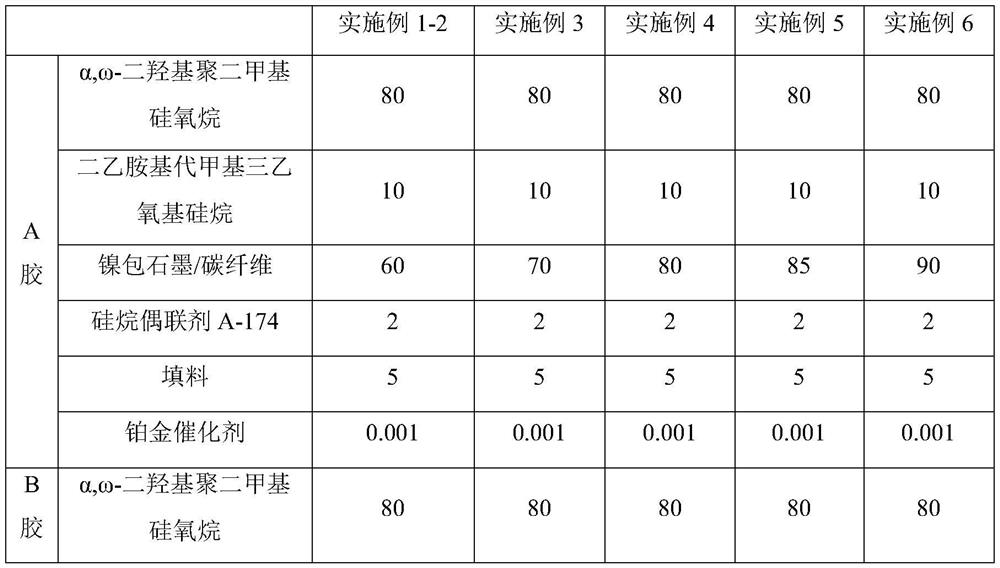

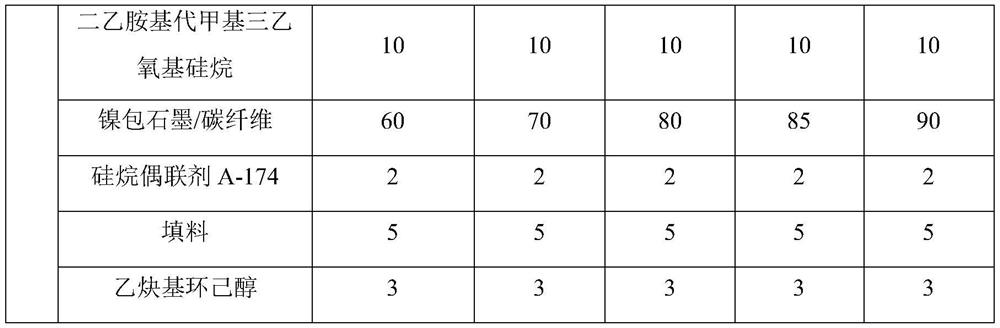

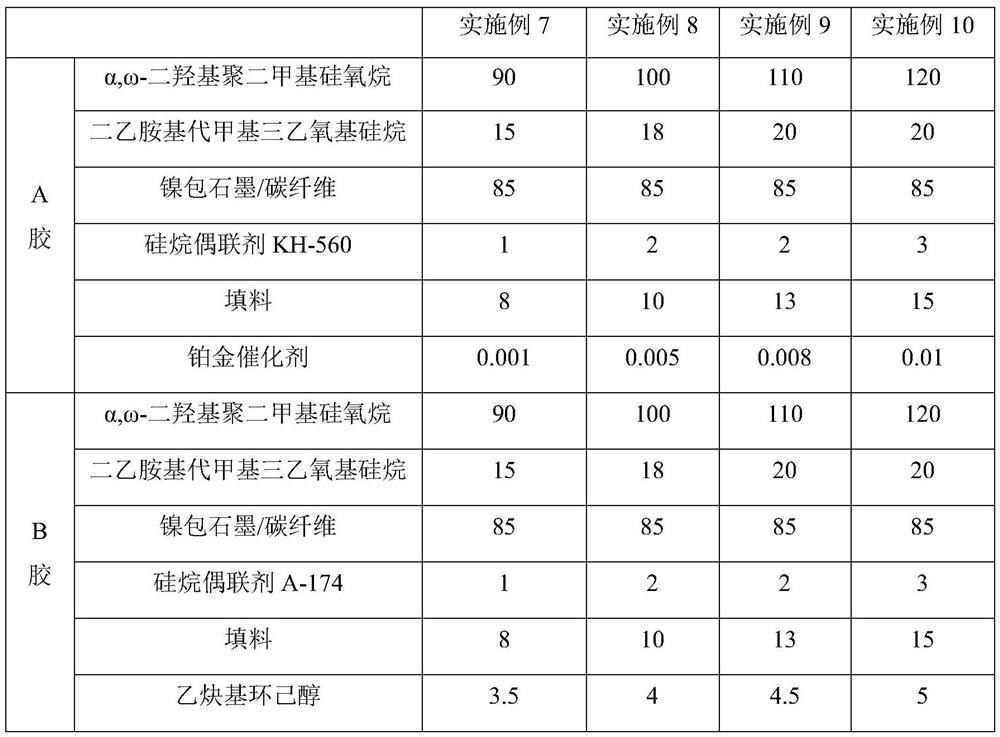

Examples

preparation example 1

[0042] A kind of nickel-coated graphite / carbon fiber in the application is prepared through the following steps:

[0043] a. Weigh graphite and carbon fiber according to the weight ratio of 1:3, and use ultrasonic treatment to uniformly mix the two to obtain graphite / carbon fiber composite material;

[0044] b. Degreasing: degreasing the above-mentioned graphite / carbon fiber composite material with 15wt% NaOH aqueous solution at 54°C for 10 minutes by ultrasonic vibration, taking out the sample, and washing it with deionized water until neutral;

[0045] c. Coarsening: use 10wt% HNO 3 The aqueous solution was roughened by ultrasonic vibration at 55°C for 10 minutes, and the sample was taken out and rinsed with deionized water until neutral;

[0046] d. Sensitization: in 37wt% hydrochloric acid 60mL / L, SnCl 2 2H 2 In the sensitization solution of O 30g / L, sensitize with ultrasonic vibration for 6min, take out the sample, and rinse it with deionized water;

[0047] e. Activa...

preparation example 2

[0051] The nickel-coated graphite / carbon fiber of Preparation Example 2 is the same as that of Preparation Example 1, except that the same amount of graphite is replaced with flexible graphite.

preparation example 3

[0053] The fumed silica-titanium dioxide composite powder in this application is prepared by the following operations:

[0054] Pretreatment of fumed silica: Add sodium polyacrylate with a total weight of 12% of the slurry under the conditions of 23°C, rotational speed 1200r / min, ball-to-material ratio 5.5:1, and slurry concentration of 2.3%, and ultrafine grinding for 80 minutes , to obtain the fumed silica after dispersion treatment;

[0055] Titanium dioxide pretreatment: Under the conditions of 24°C, rotational speed 1200r / min, ball-to-material ratio 4:1, and slurry concentration 50%, ultra-fine grinding for 60 minutes to obtain dispersed titanium dioxide;

[0056] Mix the treated fumed silica and titanium dioxide in a weight ratio of 1:0.5, control the slurry concentration to 12%, ultra-fine grinding for 40 minutes, and sieve to obtain a silica / titanium dioxide composite material with an average particle size of 1000 mesh .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com