Anticorrosive paint and preparation method thereof

A technology for anti-corrosion coatings and coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as high binding force requirements and slow drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

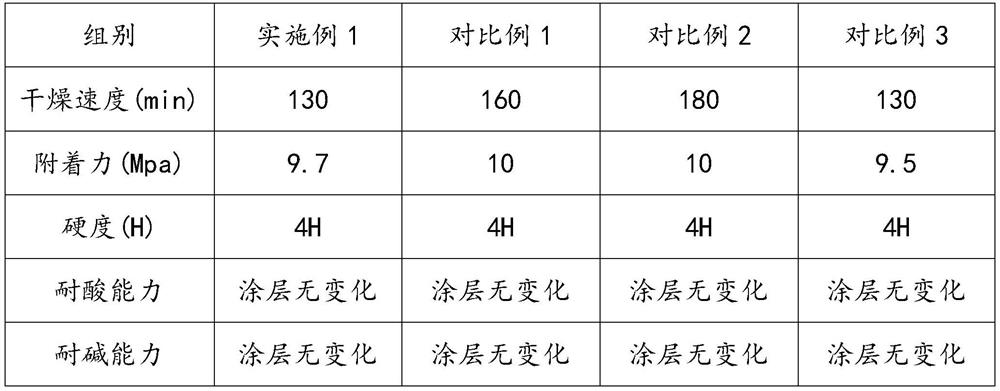

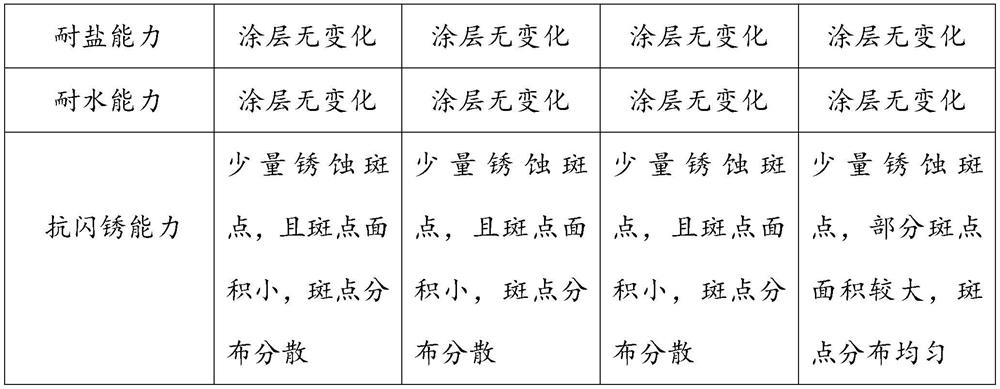

Examples

Embodiment 1

[0047] A kind of anti-corrosion coating, this anti-corrosion coating comprises lining coating and surface coating, wherein lining coating is prepared by the raw material of following weight part:

[0048] 30 parts by weight of epoxy resin, 3.5 parts by weight of epoxy resin reactive diluent, 0.35 parts by weight of water-based anti-flash rust agent, 8 parts by weight of sepiolite powder, 0.25 parts by weight of modified polyethylene fiber, 8 parts by weight of filler, water-based dispersant 0.2 parts by weight and 13 parts by weight of water;

[0049] Described epoxy resin reactive diluent is phenyl glycidyl ether;

[0050] The filler is quartz powder;

[0051] The surface active component is prepared from the following raw materials in parts by weight:

[0052] 30 parts by weight of epoxy resin, 3.5 parts by weight of epoxy resin reactive diluent, 1.2 parts by weight of glass flakes, 8 parts by weight of sepiolite powder, 8 parts by weight of filler, 0.2 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com