Laser cutting protection liquid as well as preparation method and application thereof

A laser cutting and protective liquid technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as internal structure damage, chip chipping, scratches, etc., to save equipment and material costs, and achieve excellent heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

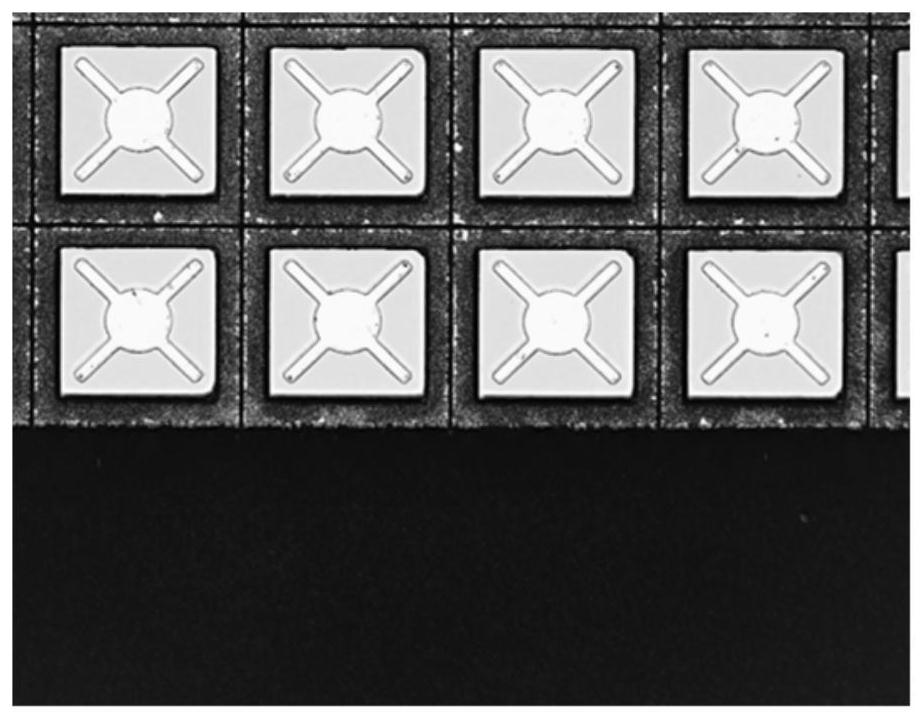

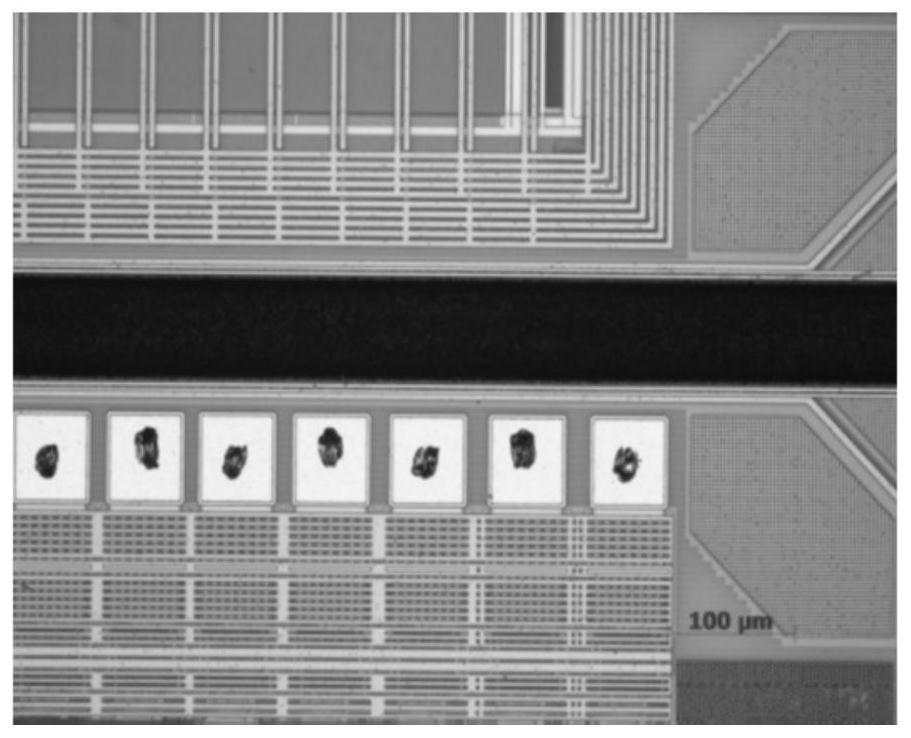

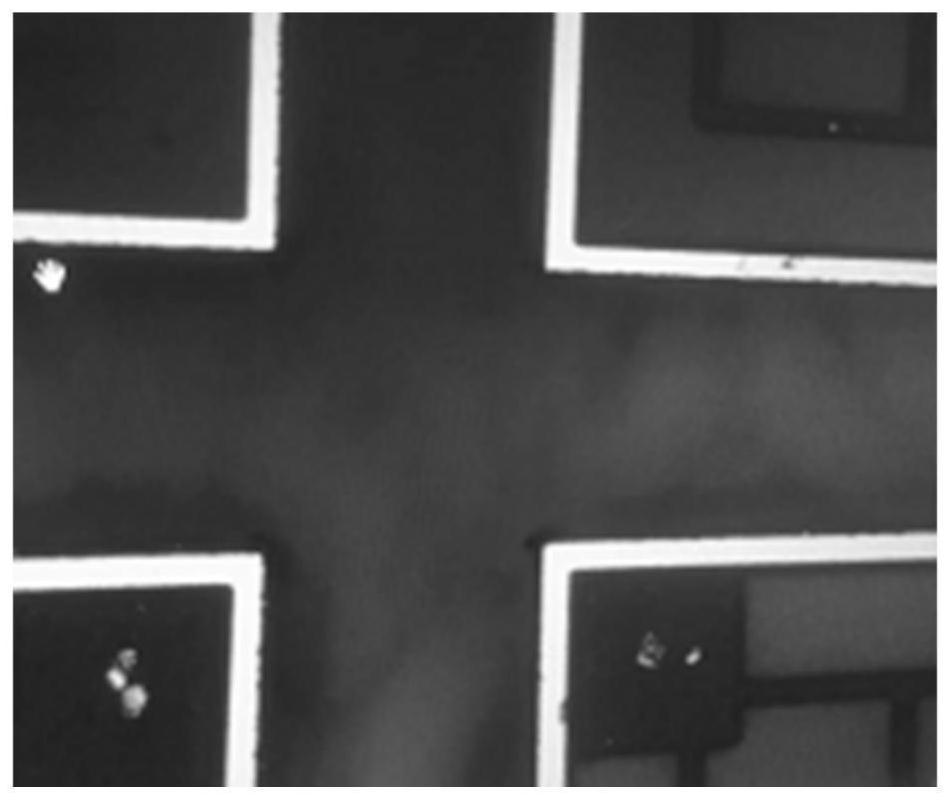

Image

Examples

Embodiment 1

[0062] The present embodiment provides a laser cutting protection solution, which includes the following components according to weight percentage: 20% water-soluble resin (polyvinylpyrrolidone, number average molecular weight 75000g / mol, purchased from BASF, the brand is Luvitec@ ), solvent 20% (diacetone alcohol), humectant 2% (propylene glycol), water-soluble UV absorber 0.5% (benzophenone-4-carboxylic acid), water-soluble antioxidant 0.25% (tannic acid) , water-soluble red pigment 5% (Food Red No. 105), pH regulator 1.5% (ethanolamine), anti-corrosion agent 0.15% (benzotriazole) and water 50.6%.

[0063] The preparation method of above-mentioned laser protective liquid is as follows:

[0064] Stir and mix the water-soluble resin, solvent and humectant in water according to the weight percentage, then add the water-soluble antioxidant, water-soluble red pigment and anti-corrosion agent according to the weight percentage, add the pH regulator according to the weight percenta...

Embodiment 2

[0066] This embodiment provides a laser cutting protection solution, which includes the following components according to weight percentage: 10% water-soluble resin (polyvinyl alcohol, number average molecular weight 60000g / mol, purchased from Chuanwei, the brand is 2488 ), solvent 5% (ethylene glycol butyl ether), humectant 0.5% (polyethylene glycol, number average molecular weight is 400g / mol, purchased from Dow Chemical, trade mark is PEG-400), water-soluble ultraviolet absorber 0.1 % (benzophenone-4,4-dicarboxylic acid), water-soluble antioxidant 0.1% (sodium sulfite), water-soluble red pigment 2% (erythrosine), pH regulator 1% (acetic acid), corrosion inhibitor 0.1% (mercaptobenzothiazole) and water 81.2%.

[0067] The preparation method of above-mentioned laser protective liquid is as follows:

[0068] Stir and mix the water-soluble resin, solvent and humectant in water according to the weight percentage, then add the water-soluble antioxidant, water-soluble red pigment...

Embodiment 3

[0070] The present embodiment provides a laser cutting protection solution, which comprises the following components according to weight percentage: 3% water-soluble resin (hydroxypropyl cellulose, number average molecular weight 90000g / mol, purchased from Dow, trade name METHOCEL K100MP), 30% solvent (ethylene glycol butyl ether and ethylene glycol tert-butyl ether with a mass ratio of 1:1), 5% humectant (dipropylene glycol and diethylene glycol with a mass ratio of 2:1), Water-soluble UV absorber 1% (2,7-anthraquinone disulfonic acid sodium salt), water-soluble antioxidant 0.5% (sodium sulfite), water-soluble red pigment 10% (carmine), pH regulator 2% (N , N-dimethylcyclohexylamine), 0.2% of corrosion inhibitor (benzothiazole and ATMP with a mass ratio of 1:1) and 48.3% of water.

[0071] The preparation method of above-mentioned laser protective liquid is as follows:

[0072]Stir and mix the water-soluble resin, solvent and humectant in water according to the weight percen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com