Powder environment-friendly heat stabilizer for slush molding products

A heat stabilizer and auxiliary stabilizer technology, applied in the field of heat stabilizer preparation, can solve the problems of high organic volatile components, high cost, and strong product odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 15 parts of powdered zinc stearate, 10 parts of calcium stearate, 15 parts of acid absorbing agent, 1 part of antioxidant, 5 parts of auxiliary stabilizer, 5 parts of coupling agent, and 10 parts of filler, and pour them in sequence In the high-speed mixer, start stirring after feeding, keep the speed at 800 rpm, and control the temperature of the material below 45°C. After mixing for 10 minutes, release the material and cool it to room temperature.

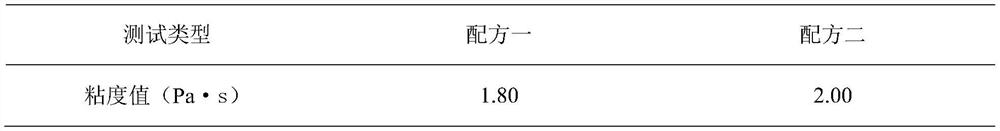

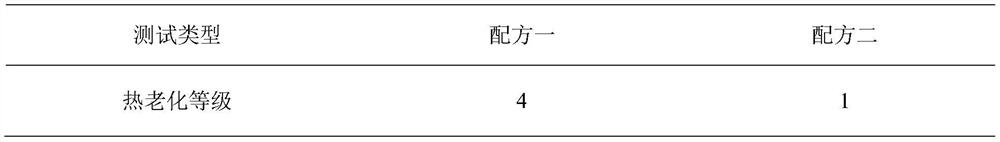

[0035] Weigh 100g of PVC paste resin, 70g of dioctyl terephthalate (DOTP), 3g of JCZ-100 liquid calcium zinc stabilizer, and record it as formula 1; 100g of PVC paste resin, 70g of dioctyl terephthalate (DOTP) , powder stabilizer 2g (the product of this embodiment) for slush molding, which is recorded as formula two. Stir evenly at room temperature, and test the colloidal viscosity and heat resistance after stirring respectively. The colloidal viscosity is shown in Table 1, and the heat resistance is shown in Table 2...

Embodiment 2

[0043] Weigh 25 parts of powdered zinc stearate, 20 parts of calcium stearate, 25 parts of acid absorbing agent, 5 parts of antioxidant, 10 parts of auxiliary stabilizer, 10 parts of coupling agent, and 20 parts of filler, and pour them in sequence In the high-speed mixer, start stirring after feeding, keep the speed at 1000 rpm, and control the temperature of the material below 45°C. After mixing for 20 minutes, release the material and cool it to room temperature.

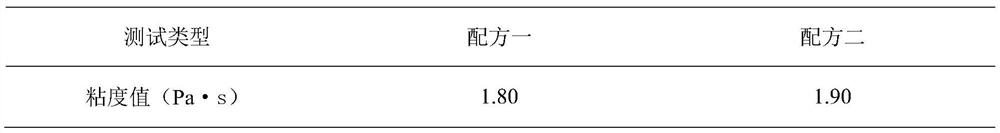

[0044] Weigh 100g of PVC paste resin, 70g of dioctyl terephthalate (DOTP), 3g of JCZ-100 liquid calcium zinc stabilizer, and record it as formula 1; 100g of PVC paste resin, 70g of dioctyl terephthalate (DOTP) , powder stabilizer 2g (the product of this embodiment) for slush molding, which is recorded as formula two. Stir evenly at room temperature, and test the colloidal viscosity and heat resistance after stirring respectively. The colloidal viscosity is shown in Table 3, and the heat resistance is shown in Tab...

Embodiment 3

[0051] Weigh 20 parts of powdered zinc stearate, 15 parts of calcium stearate, 20 parts of acid absorbing agent, 3 parts of antioxidant, 7 parts of auxiliary stabilizer, 7 parts of coupling agent, and 15 parts of filler, and pour them in sequence In the high-speed mixer, start stirring after feeding, keep the speed at 900 rpm, and control the temperature of the material below 45°C. After mixing for 15 minutes, release the material and cool it to room temperature.

[0052] Weigh 100g of PVC paste resin, 70g of dioctyl terephthalate (DOTP), 3g of JCZ-100 liquid calcium zinc stabilizer, and record it as formula 1; 100g of PVC paste resin, 70g of dioctyl terephthalate (DOTP) , powder stabilizer 2g (the product of this embodiment) for slush molding, which is recorded as formula two. Stir evenly at room temperature, and test the colloidal viscosity and heat resistance after stirring respectively. The colloidal viscosity is shown in Table 5, and the heat resistance is shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com